Absorbed Glass Mat (AGM) batteries feature a tightly wound fiberglass mat that absorbs electrolyte, offering superior vibration resistance and lower internal resistance compared to traditional Spiral Cell batteries. Spiral Cell batteries employ coiled electrodes to enhance surface area and improve energy density, making them ideal for high-performance, deep-cycle applications. AGM batteries generally provide better cold-cranking amps and longer life under high-stress conditions, while Spiral Cell designs excel in sustained power output and faster recharge times.

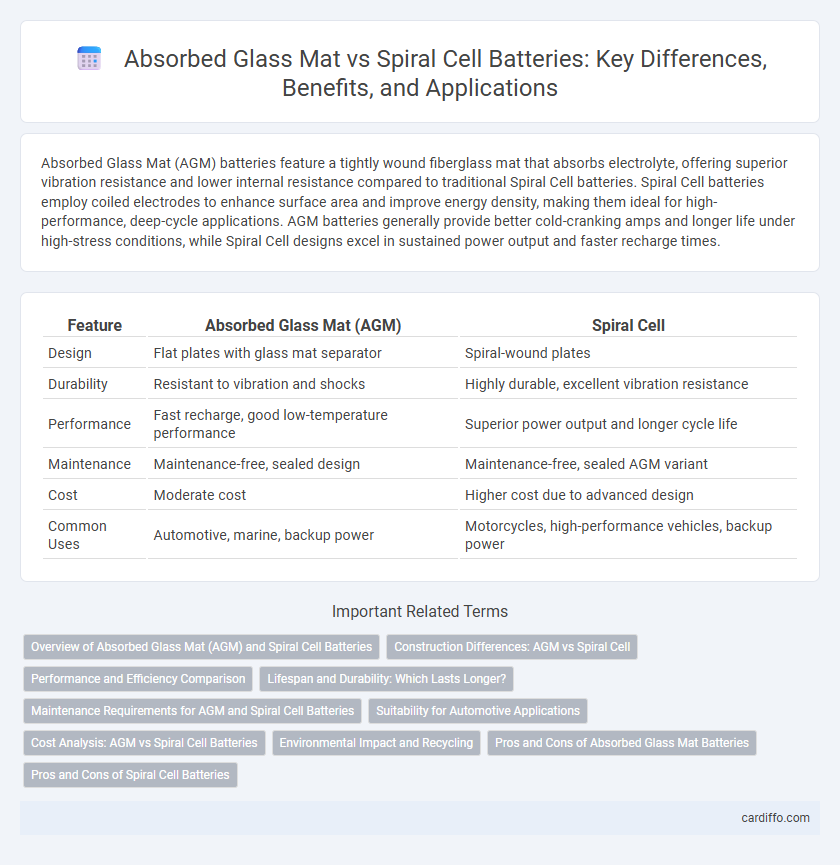

Table of Comparison

| Feature | Absorbed Glass Mat (AGM) | Spiral Cell |

|---|---|---|

| Design | Flat plates with glass mat separator | Spiral-wound plates |

| Durability | Resistant to vibration and shocks | Highly durable, excellent vibration resistance |

| Performance | Fast recharge, good low-temperature performance | Superior power output and longer cycle life |

| Maintenance | Maintenance-free, sealed design | Maintenance-free, sealed AGM variant |

| Cost | Moderate cost | Higher cost due to advanced design |

| Common Uses | Automotive, marine, backup power | Motorcycles, high-performance vehicles, backup power |

Overview of Absorbed Glass Mat (AGM) and Spiral Cell Batteries

Absorbed Glass Mat (AGM) batteries use a fiberglass mat to absorb electrolyte, providing enhanced vibration resistance and faster charging compared to traditional flooded batteries. Spiral Cell batteries feature tightly wound lead plates designed to maximize surface area, resulting in higher power density and improved deep cycle performance. Both battery types offer maintenance-free operation and superior durability, making them ideal for demanding automotive and marine applications.

Construction Differences: AGM vs Spiral Cell

Absorbed Glass Mat (AGM) batteries feature a design where the electrolyte is absorbed into a fiberglass mat separator, allowing for a sealed, spill-proof construction that enhances vibration resistance and reduces maintenance. Spiral cell batteries consist of rolled electrode plates tightly coiled with a fiberglass separator, promoting a compact structure that improves surface area and gas recombination efficiency, leading to faster recharge capabilities. The key construction difference lies in AGM's flat plate arrangement within a rigid casing versus spiral cell's cylindrical, wound electrode design, impacting performance characteristics such as durability and charging speed.

Performance and Efficiency Comparison

Absorbed Glass Mat (AGM) batteries feature tightly wound glass fibers that enhance electrolyte absorption, resulting in lower internal resistance and improved cold-cranking performance compared to Spiral Cell batteries. Spiral Cell batteries utilize coiled plates that increase surface area, providing superior energy density and longer cycle life, which boosts overall efficiency in high-demand applications. AGM batteries excel in rapid charge acceptance and vibration resistance, whereas Spiral Cell designs offer enhanced durability and sustained power output under continuous discharge.

Lifespan and Durability: Which Lasts Longer?

Absorbed Glass Mat (AGM) batteries typically offer longer lifespan and superior durability compared to Spiral Cell batteries due to their robust design that resists vibration and deep cycling damage. Spiral Cell batteries, while known for high power output and compact size, generally exhibit shorter lifespans under heavy usage and are more susceptible to capacity loss over time. For applications demanding long-term reliability and endurance, AGM batteries are often the preferred choice, with operational life extending up to 5-7 years under optimal conditions.

Maintenance Requirements for AGM and Spiral Cell Batteries

AGM batteries require minimal maintenance due to their sealed design, preventing electrolyte loss and eliminating the need for water refilling. Spiral cell batteries, also sealed, offer similar maintenance-free benefits but excel in durability and resistance to vibration, reducing the risk of internal damage during use. Both types maintain optimal performance without regular electrolyte checks, making them ideal for applications demanding reliability and low upkeep.

Suitability for Automotive Applications

Absorbed Glass Mat (AGM) batteries offer superior vibration resistance and faster recharge times, making them highly suitable for modern automotive applications with stop-start systems and increased electrical demands. Spiral Cell batteries provide exceptional durability and electrical performance under extreme temperature conditions, ideal for heavy-duty vehicles and high-performance engines. Choosing between AGM and Spiral Cell largely depends on the vehicle's specific power needs and operating environment.

Cost Analysis: AGM vs Spiral Cell Batteries

Absorbed Glass Mat (AGM) batteries typically incur higher initial costs due to advanced design and sealed construction, enhancing durability and maintenance-free operation. Spiral cell batteries often come at a premium price because of their superior energy density, longer cycle life, and better performance under extreme conditions. When analyzing total cost of ownership, AGM batteries may present lower upfront expenses but shorter lifespan, whereas spiral cell solutions justify higher investment through extended service life and lower replacement frequency.

Environmental Impact and Recycling

Absorbed Glass Mat (AGM) batteries contain fewer hazardous materials, making them easier to recycle and less harmful to the environment compared to Spiral Cell batteries, which often use more complex lead and acid mixtures. AGM batteries have a sealed design that minimizes acid leakage, reducing soil and water contamination risks during disposal. The efficient recycling process of AGM batteries recovers up to 99% of lead and other valuable materials, supporting sustainable battery lifecycle management.

Pros and Cons of Absorbed Glass Mat Batteries

Absorbed Glass Mat (AGM) batteries offer superior vibration resistance and spill-proof design, making them ideal for off-road and marine applications. They feature low internal resistance, which allows for faster charging and high power output but can be more expensive compared to spiral cell batteries. However, AGM batteries have a lower cycle life and are more sensitive to overcharging, requiring precise battery management systems to maximize performance.

Pros and Cons of Spiral Cell Batteries

Spiral cell batteries offer higher energy density and longer cycle life compared to Absorbed Glass Mat (AGM) batteries, making them ideal for applications requiring frequent deep discharges and extended runtime. Their compact design allows better heat dissipation and improved vibration resistance, enhancing durability in automotive and marine environments. However, spiral cell batteries generally come at a higher cost and may have a slightly reduced cold cranking performance compared to AGM batteries.

Absorbed Glass Mat vs Spiral Cell Infographic

cardiffo.com

cardiffo.com