Absorbed Glass Mat (AGM) batteries use a fiberglass mat to absorb electrolyte, providing better vibration resistance and lower maintenance compared to Flooded Lead-acid (FLA) batteries, which require periodic water refilling and ventilation. AGM batteries typically offer faster charging times and longer lifespan due to their sealed design, making them ideal for high-performance or deep-cycle applications. In contrast, flooded lead-acid batteries are often more cost-effective and easier to recycle but are bulkier and less efficient in extreme temperatures.

Table of Comparison

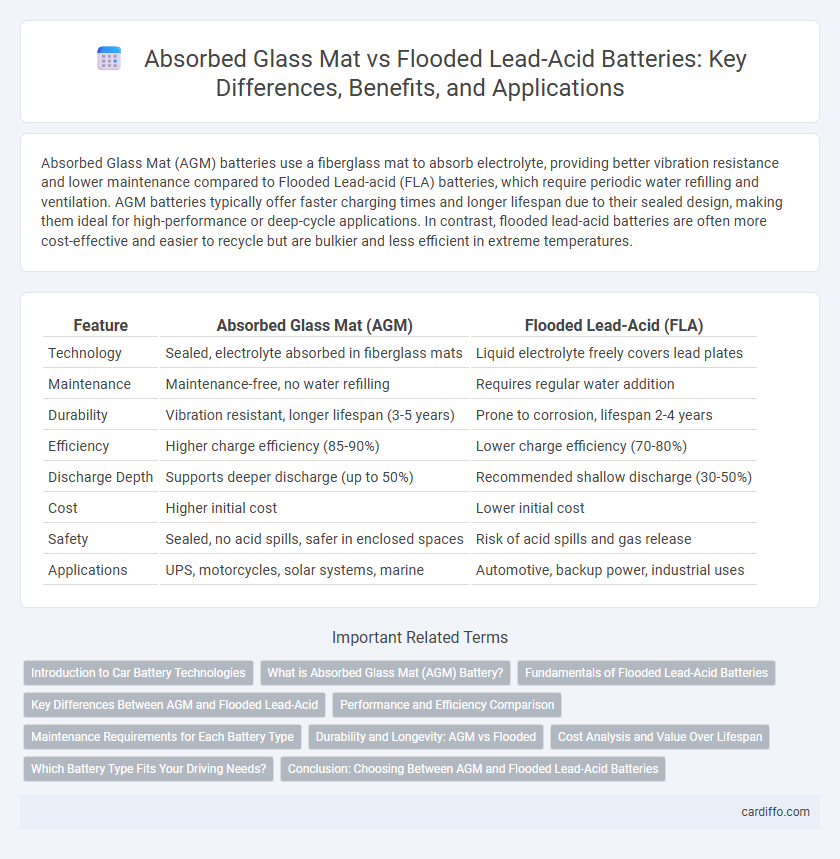

| Feature | Absorbed Glass Mat (AGM) | Flooded Lead-Acid (FLA) |

|---|---|---|

| Technology | Sealed, electrolyte absorbed in fiberglass mats | Liquid electrolyte freely covers lead plates |

| Maintenance | Maintenance-free, no water refilling | Requires regular water addition |

| Durability | Vibration resistant, longer lifespan (3-5 years) | Prone to corrosion, lifespan 2-4 years |

| Efficiency | Higher charge efficiency (85-90%) | Lower charge efficiency (70-80%) |

| Discharge Depth | Supports deeper discharge (up to 50%) | Recommended shallow discharge (30-50%) |

| Cost | Higher initial cost | Lower initial cost |

| Safety | Sealed, no acid spills, safer in enclosed spaces | Risk of acid spills and gas release |

| Applications | UPS, motorcycles, solar systems, marine | Automotive, backup power, industrial uses |

Introduction to Car Battery Technologies

Absorbed Glass Mat (AGM) batteries utilize a fiberglass mat separator that absorbs electrolyte, offering superior vibration resistance and faster recharge times compared to traditional Flooded Lead-acid batteries, which contain liquid electrolyte prone to spillage and require regular maintenance. AGM batteries provide enhanced performance and longevity in modern vehicles with advanced electrical systems, while Flooded Lead-acid batteries remain common due to lower initial cost and simplicity. Understanding these differences is crucial for selecting the optimal car battery technology based on vehicle requirements and usage conditions.

What is Absorbed Glass Mat (AGM) Battery?

Absorbed Glass Mat (AGM) batteries utilize a fiberglass mat separator that absorbs and immobilizes the electrolyte, preventing spills and enabling a sealed design. AGM batteries offer superior vibration resistance, faster recharge times, and lower internal resistance compared to flooded lead-acid batteries, making them ideal for high-performance and deep-cycle applications. Their maintenance-free nature and enhanced durability provide advantages in automotive, marine, and renewable energy storage systems.

Fundamentals of Flooded Lead-Acid Batteries

Flooded lead-acid batteries feature liquid electrolyte suspended in the battery casing, allowing for easy maintenance through electrolyte top-ups and visual inspections. Their robust design supports high surge currents and is commonly used in automotive and industrial applications due to cost-effectiveness and reliability. However, they require proper ventilation to prevent gas buildup and are susceptible to acid stratification and water loss during operation.

Key Differences Between AGM and Flooded Lead-Acid

Absorbed Glass Mat (AGM) batteries use fiberglass mats to absorb electrolyte, providing spill-proof, vibration-resistant, and maintenance-free operation, while Flooded Lead-Acid batteries contain liquid electrolyte requiring regular maintenance and ventilation. AGM batteries offer faster recharge times and better deep-cycle capabilities compared to the slower charging Flooded Lead-Acid types, which are more prone to sulfation if not properly maintained. Temperature tolerance and shelf life are superior in AGM batteries, making them ideal for high-performance and extreme conditions, whereas Flooded Lead-Acid batteries are cost-effective and preferred for applications with consistent access to maintenance.

Performance and Efficiency Comparison

Absorbed Glass Mat (AGM) batteries deliver higher performance and efficiency than Flooded Lead-Acid batteries due to their superior charge acceptance and lower internal resistance, resulting in faster recharge times and reduced energy loss. AGM technology enables better deep-cycle capabilities and longer service life with minimal maintenance, contrasting with the frequent watering and ventilation required by Flooded batteries. The sealed design of AGM batteries enhances safety by preventing acid spills and gas emissions, further optimizing reliability and operational efficiency in various applications.

Maintenance Requirements for Each Battery Type

Absorbed Glass Mat (AGM) batteries require minimal maintenance as they are sealed and do not need water refilling, reducing the risk of acid spills and corrosion. Flooded Lead-acid batteries demand regular maintenance, including periodic checking and topping off of electrolyte levels to prevent sulfation and ensure optimal performance. Proper maintenance practices for Flooded Lead-acid batteries include equalizing charges and cleaning terminals to extend battery lifespan and maintain efficiency.

Durability and Longevity: AGM vs Flooded

Absorbed Glass Mat (AGM) batteries exhibit superior durability compared to Flooded Lead-Acid batteries due to their sealed, maintenance-free design and enhanced resistance to vibration and shock. AGM batteries typically offer a longer lifespan, often reaching 4 to 7 years, while Flooded Lead-Acid batteries generally last 3 to 5 years under similar usage conditions. The improved cycle life and reduced sulfation risk in AGM technology contribute significantly to its extended longevity in demanding applications.

Cost Analysis and Value Over Lifespan

Absorbed Glass Mat (AGM) batteries typically have a higher initial cost compared to Flooded Lead-acid (FLA) batteries, but their longer lifespan and reduced maintenance needs often lead to lower total cost of ownership over time. FLA batteries require regular watering and ventilation, increasing operational expenses despite their lower upfront price. When factoring in cycle life and efficiency, AGM batteries provide better value, especially in applications demanding reliability and minimal downtime.

Which Battery Type Fits Your Driving Needs?

Absorbed Glass Mat (AGM) batteries offer superior vibration resistance, faster charging, and lower maintenance, making them ideal for vehicles with start-stop technology or frequent short trips. Flooded Lead-acid batteries, known for their affordability and ease of replacement, perform well in standard driving conditions with regular deep cycling. Selecting the right battery depends on driving habits, budget, and vehicle electrical demands, with AGM favored for modern, high-demand applications and Flooded Lead-acid suited for traditional, long-distance use.

Conclusion: Choosing Between AGM and Flooded Lead-Acid Batteries

Absorbed Glass Mat (AGM) batteries deliver superior performance in deep cycling, maintenance-free operation, and resistance to vibration, making them ideal for applications requiring reliability and longevity with minimal upkeep. Flooded Lead-Acid batteries offer cost-effectiveness and easier recycling but require regular maintenance and ventilation due to acid spillage risks and gas emissions. Selecting between AGM and Flooded Lead-Acid batteries depends on balancing budget constraints, maintenance capacity, and performance requirements specific to the intended use case.

Absorbed Glass Mat vs Flooded Lead-acid Infographic

cardiffo.com

cardiffo.com