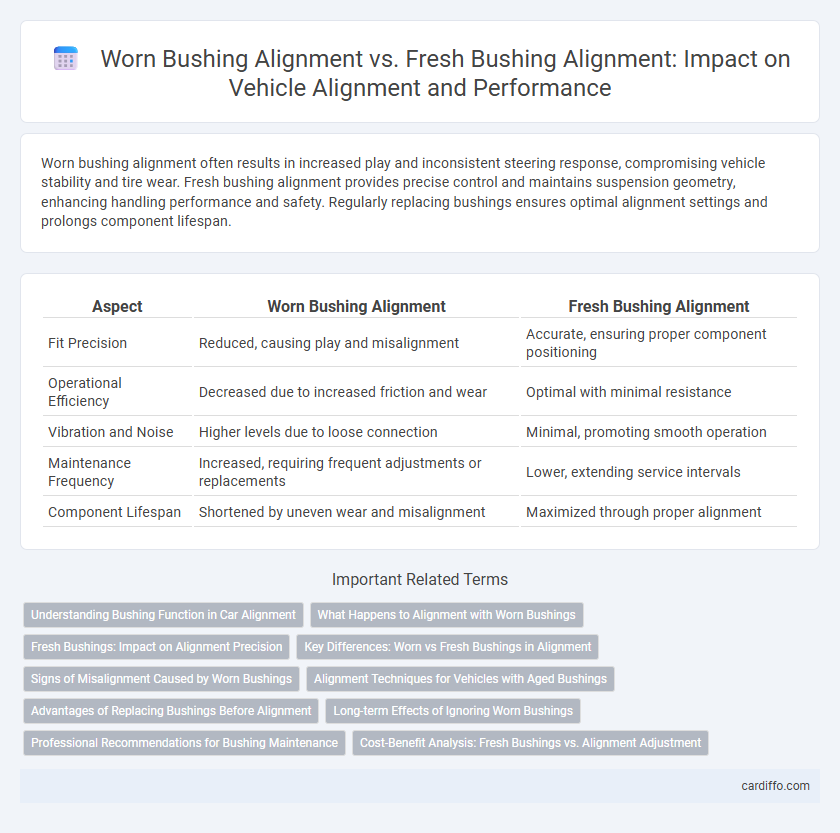

Worn bushing alignment often results in increased play and inconsistent steering response, compromising vehicle stability and tire wear. Fresh bushing alignment provides precise control and maintains suspension geometry, enhancing handling performance and safety. Regularly replacing bushings ensures optimal alignment settings and prolongs component lifespan.

Table of Comparison

| Aspect | Worn Bushing Alignment | Fresh Bushing Alignment |

|---|---|---|

| Fit Precision | Reduced, causing play and misalignment | Accurate, ensuring proper component positioning |

| Operational Efficiency | Decreased due to increased friction and wear | Optimal with minimal resistance |

| Vibration and Noise | Higher levels due to loose connection | Minimal, promoting smooth operation |

| Maintenance Frequency | Increased, requiring frequent adjustments or replacements | Lower, extending service intervals |

| Component Lifespan | Shortened by uneven wear and misalignment | Maximized through proper alignment |

Understanding Bushing Function in Car Alignment

Worn bushing alignment causes excessive play and misalignment in suspension components, leading to uneven tire wear and reduced vehicle stability. Fresh bushing alignment ensures precise control of suspension geometry by maintaining proper alignment angles, promoting optimal tire contact and smooth handling. Understanding bushing function is critical for diagnosing alignment issues and restoring accurate suspension performance.

What Happens to Alignment with Worn Bushings

Alignment with worn bushings deteriorates as increased play and movement within the suspension components cause shifts in wheel positioning. The wear reduces bushing stiffness, leading to inconsistent camber, caster, and toe angles that negatively impact handling and tire wear. Regular inspection and timely bushing replacement are essential to maintain precise alignment and vehicle stability.

Fresh Bushings: Impact on Alignment Precision

Fresh bushings significantly enhance alignment precision by providing a stable and uniform interface that minimizes lateral movement and vibration during machine operation. Unlike worn bushings, which introduce play and uneven surfaces leading to misalignment, fresh bushings maintain original tolerances and improve load distribution across the aligned components. This stability directly translates to reduced wear on parts and prolonged machinery lifespan, making fresh bushing installation critical for optimal alignment performance.

Key Differences: Worn vs Fresh Bushings in Alignment

Worn bushings cause misalignment by allowing increased play and unwanted movement in suspension components, leading to inaccurate wheel alignment measurements. Fresh bushings maintain precise alignment by minimizing vibrations and ensuring stable positioning of suspension parts, resulting in improved handling and tire wear. The key difference lies in the inherent rigidity of fresh bushings compared to the degraded elasticity of worn bushings, which directly impacts alignment accuracy and vehicle performance.

Signs of Misalignment Caused by Worn Bushings

Signs of misalignment caused by worn bushings include increased vibration, uneven wear patterns on machinery components, and excessive noise during operation. Worn bushings lose their ability to absorb shocks and maintain proper alignment, leading to accelerated wear on shafts and bearings. Detecting these symptoms early helps prevent costly equipment failure and maintain optimal performance.

Alignment Techniques for Vehicles with Aged Bushings

Alignment techniques for vehicles with aged, worn bushings require precise measurement tools such as laser alignment systems or computerized wheel alignment machines to compensate for bushing play and deformation. Technicians often perform a thorough inspection of suspension components to assess bushing wear and may use shim adjustments or alignment fixtures that account for the slight shifts caused by degraded bushings. Proper alignment focusing on caster, camber, and toe angles ensures optimal handling and tire wear, compensating for the reduced stability introduced by worn bushings.

Advantages of Replacing Bushings Before Alignment

Replacing worn bushings before alignment ensures accurate suspension geometry, improving vehicle handling and tire life. Fresh bushings eliminate excess play and vibration, allowing precise adjustment of camber, caster, and toe angles. This preventative measure reduces wear on other suspension components and enhances overall safety.

Long-term Effects of Ignoring Worn Bushings

Ignoring worn bushings during alignment leads to persistent misalignment, increasing uneven tire wear and reducing suspension efficiency over time. This neglect accelerates component fatigue and can cause premature failure of steering parts. Consistently addressing worn bushings in alignment procedures ensures optimal vehicle handling and prolongs the lifespan of suspension systems.

Professional Recommendations for Bushing Maintenance

Professional recommendations for bushing maintenance emphasize inspecting worn bushings regularly to detect misalignment early, as worn bushings can cause increased vibration and uneven wear. Fresh bushing alignment ensures optimal load distribution and reduces stress on adjacent components, prolonging equipment life. Technicians advise replacing worn bushings promptly to restore proper alignment and maintain machinery performance.

Cost-Benefit Analysis: Fresh Bushings vs. Alignment Adjustment

Worn bushing alignment often leads to increased machinery vibration and uneven wear, resulting in higher maintenance costs and reduced operational efficiency. Investing in fresh bushings improves alignment precision, extending equipment lifespan and minimizing downtime, which offsets the initial replacement expense. Analyzing the cost-benefit reveals that the long-term savings from reduced repairs and enhanced performance outweigh the upfront costs of fresh bushing installation compared to mere alignment adjustments on worn components.

Worn bushing alignment vs fresh bushing alignment Infographic

cardiffo.com

cardiffo.com