Aligning a pet with a string provides a tactile, visual guide that helps maintain consistent positioning during training or tasks, fostering steady focus and control. In contrast, aligning with a laser offers a precise, dynamic point that can quickly direct a pet's attention but may encourage chasing behavior rather than steady alignment. Choosing between string and laser alignment depends on the desired training outcome and the pet's responsiveness to visual stimuli.

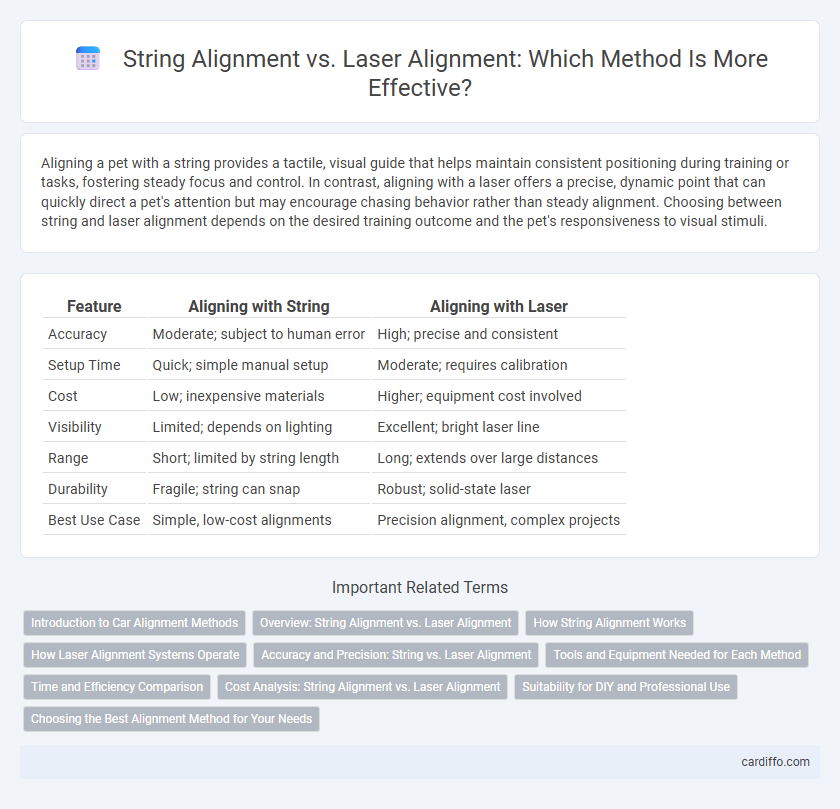

Table of Comparison

| Feature | Aligning with String | Aligning with Laser |

|---|---|---|

| Accuracy | Moderate; subject to human error | High; precise and consistent |

| Setup Time | Quick; simple manual setup | Moderate; requires calibration |

| Cost | Low; inexpensive materials | Higher; equipment cost involved |

| Visibility | Limited; depends on lighting | Excellent; bright laser line |

| Range | Short; limited by string length | Long; extends over large distances |

| Durability | Fragile; string can snap | Robust; solid-state laser |

| Best Use Case | Simple, low-cost alignments | Precision alignment, complex projects |

Introduction to Car Alignment Methods

Car alignment methods primarily include aligning with string and aligning with laser techniques, each offering precision in vehicle wheel positioning. Aligning with string involves setting up taut strings around the wheels to measure camber, caster, and toe angles manually, providing a cost-effective but labor-intensive approach. Laser alignment uses advanced laser beams and sensors to deliver highly accurate, quick adjustments and digital readouts, making it the preferred method in modern auto repair shops for enhanced accuracy and efficiency.

Overview: String Alignment vs. Laser Alignment

String alignment relies on physical lines for precision and is highly effective for short distances or low-budget projects, offering simplicity and ease of use. Laser alignment provides greater accuracy and efficiency, especially for long distances or complex setups, utilizing laser beams to detect misalignment with minimal human error. Both methods serve distinct purposes, with laser alignment favored in industrial and technical applications and string alignment common in construction and manual tasks.

How String Alignment Works

String alignment relies on a taut string stretched between two fixed points to create a precise visual reference line for measurement and layout tasks. This method is effective for ensuring straightness over long distances and is commonly used in construction and woodworking for aligning walls, posts, or other structural elements. Unlike laser alignment, string alignment requires manual adjustment and is less suitable for highly detailed or indoor applications where laser precision excels.

How Laser Alignment Systems Operate

Laser alignment systems operate by projecting a precise laser beam between measurement targets to detect angular and positional deviations with high accuracy. The technology utilizes sensors to capture discrepancies in the laser path, enabling real-time adjustments to machinery components for optimal alignment. This method outperforms traditional string alignment by providing faster, more accurate, and repeatable results that reduce setup time and increase equipment reliability.

Accuracy and Precision: String vs. Laser Alignment

Laser alignment offers superior accuracy and precision compared to string alignment by utilizing advanced optical technology that minimizes human error and environmental interference. String alignment, while cost-effective, often suffers from sagging and tension inconsistencies, reducing its reliability for tasks requiring exact measurements. Precision in laser alignment enables repeatable and highly detailed adjustments critical in engineering and construction projects demanding strict tolerances.

Tools and Equipment Needed for Each Method

Aligning with string requires basic tools such as a taut string, stakes, and measuring tape to ensure straight lines and consistent spacing, making it ideal for simple tasks and low-cost projects. In contrast, laser alignment demands specialized equipment including a laser level, tripods, and target detectors to achieve high precision and accuracy in complex or large-scale constructions. The choice between these methods depends on project requirements, with laser tools offering advanced control and efficiency despite higher costs and technical expertise needed.

Time and Efficiency Comparison

Aligning with laser systems significantly reduces setup time by providing precise, real-time feedback, allowing quicker adjustments compared to manual string alignment which is more time-consuming and prone to human error. Laser alignment improves operational efficiency by minimizing alignment errors and the need for multiple adjustments, resulting in faster project completion and reduced downtime. This precision-driven approach enhances overall workflow productivity in industrial and construction applications.

Cost Analysis: String Alignment vs. Laser Alignment

String alignment typically incurs lower upfront costs, relying on basic tools and manual labor, making it suitable for smaller projects or budgets. Laser alignment involves higher initial investment due to advanced equipment and technology but offers greater precision and reduced downtime, which can translate to long-term cost savings. Analyzing total cost of ownership highlights that laser alignment minimizes rework and maintenance expenses compared to string alignment, particularly in complex or large-scale applications.

Suitability for DIY and Professional Use

Aligning with string is highly suitable for DIY projects due to its low cost, simplicity, and ease of use, making it accessible for beginners and home improvement tasks. Laser alignment offers superior precision and speed, preferred by professionals in construction and engineering fields where accuracy and efficiency are critical. The choice depends on project complexity, with string alignment fitting basic needs and laser alignment excelling in detailed, large-scale applications.

Choosing the Best Alignment Method for Your Needs

Choosing between string alignment and laser alignment depends on accuracy requirements and project complexity. String alignment offers a cost-effective and straightforward method for basic setups, while laser alignment provides high precision and is ideal for detailed or industrial applications. Evaluate factors such as alignment tolerance, environmental conditions, and budget to select the most suitable technique.

Aligning with String vs Aligning with Laser Infographic

cardiffo.com

cardiffo.com