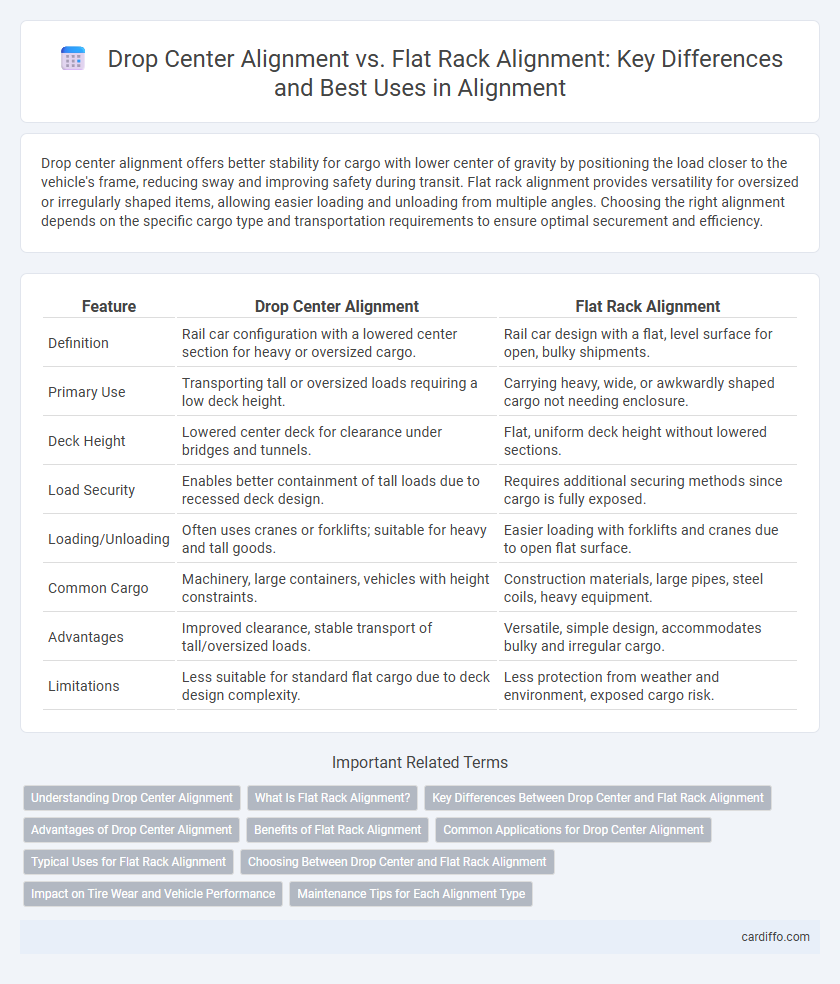

Drop center alignment offers better stability for cargo with lower center of gravity by positioning the load closer to the vehicle's frame, reducing sway and improving safety during transit. Flat rack alignment provides versatility for oversized or irregularly shaped items, allowing easier loading and unloading from multiple angles. Choosing the right alignment depends on the specific cargo type and transportation requirements to ensure optimal securement and efficiency.

Table of Comparison

| Feature | Drop Center Alignment | Flat Rack Alignment |

|---|---|---|

| Definition | Rail car configuration with a lowered center section for heavy or oversized cargo. | Rail car design with a flat, level surface for open, bulky shipments. |

| Primary Use | Transporting tall or oversized loads requiring a low deck height. | Carrying heavy, wide, or awkwardly shaped cargo not needing enclosure. |

| Deck Height | Lowered center deck for clearance under bridges and tunnels. | Flat, uniform deck height without lowered sections. |

| Load Security | Enables better containment of tall loads due to recessed deck design. | Requires additional securing methods since cargo is fully exposed. |

| Loading/Unloading | Often uses cranes or forklifts; suitable for heavy and tall goods. | Easier loading with forklifts and cranes due to open flat surface. |

| Common Cargo | Machinery, large containers, vehicles with height constraints. | Construction materials, large pipes, steel coils, heavy equipment. |

| Advantages | Improved clearance, stable transport of tall/oversized loads. | Versatile, simple design, accommodates bulky and irregular cargo. |

| Limitations | Less suitable for standard flat cargo due to deck design complexity. | Less protection from weather and environment, exposed cargo risk. |

Understanding Drop Center Alignment

Drop center alignment centers the cargo over a recessed section of the floor, ensuring balanced weight distribution and enhanced stability during transport. This method reduces stress on securing points and minimizes cargo movement by aligning the load with the vehicle's designed support areas. Proper understanding of drop center alignment is crucial for optimizing safety and efficiency in freight handling compared to flat rack alignment.

What Is Flat Rack Alignment?

Flat Rack Alignment is the process of arranging shipping containers or heavy cargo evenly on a flat rack, ensuring weight distribution is balanced and secure for transport, especially suited for oversized or irregularly shaped items. Unlike drop center alignment, which relies on containers with recessed bases to fit into vessel holds, flat rack alignment uses open-frame racks that support cargo from the base and sides, facilitating easier loading and unloading. Precise flat rack alignment minimizes the risk of cargo shift and damage, enhancing safety during maritime or land transport.

Key Differences Between Drop Center and Flat Rack Alignment

Drop center alignment features a recessed area in the middle of the rack, enabling easier stacking and interlocking of goods, which improves stability during transport. Flat rack alignment consists of a flat, even surface without recesses, offering versatility for oversized or irregularly shaped items but less inherent stacking security. The key difference lies in drop center's enhanced load stability through design versus flat rack's adaptability to varied cargo dimensions.

Advantages of Drop Center Alignment

Drop center alignment offers enhanced stability by centering the load, reducing sway during transportation compared to flat rack alignment. It provides easier loading and unloading due to the lowered center platform, increasing operational efficiency. This alignment optimizes weight distribution, minimizing strain on lifting equipment and extending container lifespan.

Benefits of Flat Rack Alignment

Flat rack alignment offers superior flexibility for transporting oversized or heavy cargo that cannot fit into standard drop center containers, ensuring safer and more efficient handling of irregular loads. Its open design facilitates easier loading and unloading, reducing time and labor costs compared to drop center alignment. Enhanced structural support in flat racks minimizes cargo movement and damage during transit, improving overall shipment security and reliability.

Common Applications for Drop Center Alignment

Drop center alignment is commonly applied in industries requiring precise handling of cylindrical or slightly curved objects, such as automotive tire mounting, wheel assembly, and pipe fitting. This alignment method ensures accurate positioning by accommodating the drop center's groove, making it ideal for tire servicing and manufacturing applications. Its use enhances stability and reduces errors in processes where round or curved surfaces must align perfectly.

Typical Uses for Flat Rack Alignment

Flat rack alignment is typically used for transporting oversized or heavy machinery, construction equipment, and large industrial components that do not fit within standard container dimensions. This alignment ensures the secure loading and unloading of goods requiring open sides or top access during transit. It is commonly employed in logistics involving heavy-duty shipments that need flexibility in handling and stacking.

Choosing Between Drop Center and Flat Rack Alignment

Choosing between drop center alignment and flat rack alignment depends on the specific loading requirements and cargo stability. Drop center alignment provides easier access for heavy or bulky items with its recessed platform, whereas flat rack alignment offers maximum surface area for irregular or oversized loads. Evaluating factors such as load shape, weight distribution, and handling equipment ensures optimal alignment selection for efficient and safe transport.

Impact on Tire Wear and Vehicle Performance

Drop center alignment minimizes uneven tire wear by ensuring the wheels maintain optimal contact with the road surface, resulting in improved vehicle stability and fuel efficiency. Flat rack alignment, while easier to set up, often leads to increased tire scrub and irregular tread wear due to less precise angling of the wheels. Choosing drop center alignment enhances long-term tire longevity and maintains better overall vehicle handling performance.

Maintenance Tips for Each Alignment Type

Drop center alignment requires regular inspection of centering mechanisms and lubricant application to ensure smooth operation and prevent wear. Flat rack alignment demands consistent checking of flat surface conditions, proper load distribution, and timely recalibration to maintain stability and accurate positioning. Both alignment types benefit from routine cleaning and immediate repairs to avoid misalignment and equipment damage.

Drop center alignment vs Flat rack alignment Infographic

cardiffo.com

cardiffo.com