Thrust alignment focuses on ensuring the propulsive force is properly directed through the shaft to prevent undue stress on bearings, while centerline alignment prioritizes the precise positioning of the shaft along the center axis of connected equipment to avoid misalignment. Accurate thrust alignment reduces axial load issues and extends bearing life, whereas centerline alignment minimizes vibration and improves coupling performance. Both methods are essential for optimal equipment reliability, but the choice depends on whether axial force or radial alignment is the primary concern.

Table of Comparison

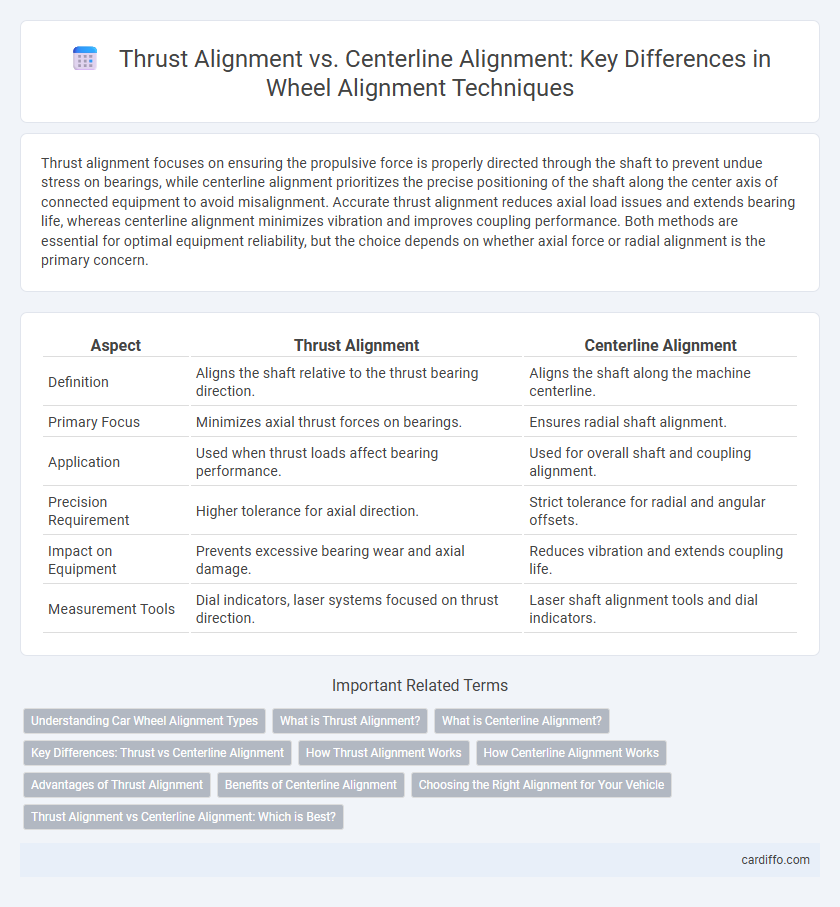

| Aspect | Thrust Alignment | Centerline Alignment |

|---|---|---|

| Definition | Aligns the shaft relative to the thrust bearing direction. | Aligns the shaft along the machine centerline. |

| Primary Focus | Minimizes axial thrust forces on bearings. | Ensures radial shaft alignment. |

| Application | Used when thrust loads affect bearing performance. | Used for overall shaft and coupling alignment. |

| Precision Requirement | Higher tolerance for axial direction. | Strict tolerance for radial and angular offsets. |

| Impact on Equipment | Prevents excessive bearing wear and axial damage. | Reduces vibration and extends coupling life. |

| Measurement Tools | Dial indicators, laser systems focused on thrust direction. | Laser shaft alignment tools and dial indicators. |

Understanding Car Wheel Alignment Types

Thrust alignment measures the rear axle's angle to ensure it is square and parallel to the vehicle's centerline, preventing the car from pulling to one side. Centerline alignment focuses on aligning the front wheels parallel to the vehicle's geometric centerline for optimal steering response and tire wear. Understanding these wheel alignment types helps maintain vehicle stability, improve handling, and extend tire life.

What is Thrust Alignment?

Thrust alignment is a method used in shaft alignment where two coupled machines are positioned so their thrust faces are in proper contact, ensuring axial loads are transferred correctly. This alignment technique focuses on aligning components to manage axial thrust forces, preventing excessive wear and potential damage to bearings and seals. Proper thrust alignment is critical in turbines, pumps, and compressors to maintain optimal performance and extend equipment lifespan.

What is Centerline Alignment?

Centerline alignment refers to the precise positioning of machinery components along a common central axis to ensure optimal operational efficiency and reduce mechanical stress. This method involves measuring and adjusting the alignment based on the shaft centerlines rather than external surfaces, which enhances accuracy in rotating equipment like pumps and motors. Proper centerline alignment minimizes vibration, prevents premature bearing and seal failure, and extends equipment lifespan by maintaining uniform load distribution.

Key Differences: Thrust vs Centerline Alignment

Thrust alignment focuses on aligning the shaft to manage axial forces created by thrust loads, ensuring proper load distribution and reduced wear on thrust bearings. Centerline alignment involves aligning machinery components along a common horizontal axis to prevent misalignment that can cause vibration and premature failure. The primary difference lies in thrust alignment addressing axial thrust forces, while centerline alignment targets radial shaft positioning for optimal rotational balance.

How Thrust Alignment Works

Thrust alignment works by adjusting the position of the machine's thrust bearing to ensure axial forces are properly managed and transmitted along the intended path, preventing shaft movement and reducing wear. Unlike centerline alignment, which focuses on aligning the shaft and bearing centers, thrust alignment targets the balance of axial thrust loads within the system. Precise calibration of thrust alignment improves machine reliability by maintaining axial stability and minimizing stress on components such as thrust bearings and seals.

How Centerline Alignment Works

Centerline alignment works by ensuring the rotational axes of coupled equipment are precisely aligned using visual tools, laser measurement, or dial indicators to measure deviations along the centerline. This method focuses on matching the centerlines of shafts or rotating components rather than just the driven components' positions, reducing misalignment-induced stresses. Proper centerline alignment enhances machinery performance, reduces wear, and prevents premature failures in pumps, motors, and turbines.

Advantages of Thrust Alignment

Thrust alignment offers precise control over axial forces by directly aligning the rotating components with the machine's thrust bearing, reducing stress and wear on critical parts. This method enhances operational stability and extends equipment lifespan by minimizing shaft misalignment and vibration. Thrust alignment is particularly advantageous in heavy machinery where accurate axial load management is essential for optimal performance.

Benefits of Centerline Alignment

Centerline alignment ensures precise shaft alignment by positioning rotating equipment along a shared rotational axis, reducing wear and preventing premature component failure. This method enhances operational efficiency, lowers vibration levels, and minimizes energy consumption compared to thrust alignment, which primarily focuses on axial load management. By optimizing equipment balance, centerline alignment improves machine reliability and extends maintenance intervals.

Choosing the Right Alignment for Your Vehicle

Choosing the right alignment between thrust alignment and centerline alignment depends on your vehicle's suspension and steering configuration. Thrust alignment ensures the rear wheels are square to the vehicle's centerline, optimizing stability and reducing tire wear for vehicles with independent rear suspension. Centerline alignment focuses on aligning all wheels to the vehicle's geometric centerline, providing precise tracking ideal for solid rear axle setups and enhancing overall handling performance.

Thrust Alignment vs Centerline Alignment: Which is Best?

Thrust alignment precisely ensures that the driving force is directed along the shaft's axis, minimizing axial loads and reducing wear on bearings, making it ideal for high-speed rotating equipment. Centerline alignment aligns machinery based on the geometric center of shafts, providing an overall balance but potentially allowing axial thrust issues. Choosing between thrust alignment and centerline alignment depends on the application's sensitivity to axial forces, with thrust alignment offering superior performance in scenarios demanding reduced axial load and enhanced equipment longevity.

Thrust Alignment vs Centerline Alignment Infographic

cardiffo.com

cardiffo.com