Active alignment involves continuous adjustments using sensors and feedback systems to maintain precise positioning in real time, enhancing accuracy and performance. Passive alignment relies on fixed components and mechanical design, offering simplicity but limited adaptability to changing conditions. Choosing between active and passive alignment depends on the application's need for flexibility, precision, and maintenance complexity.

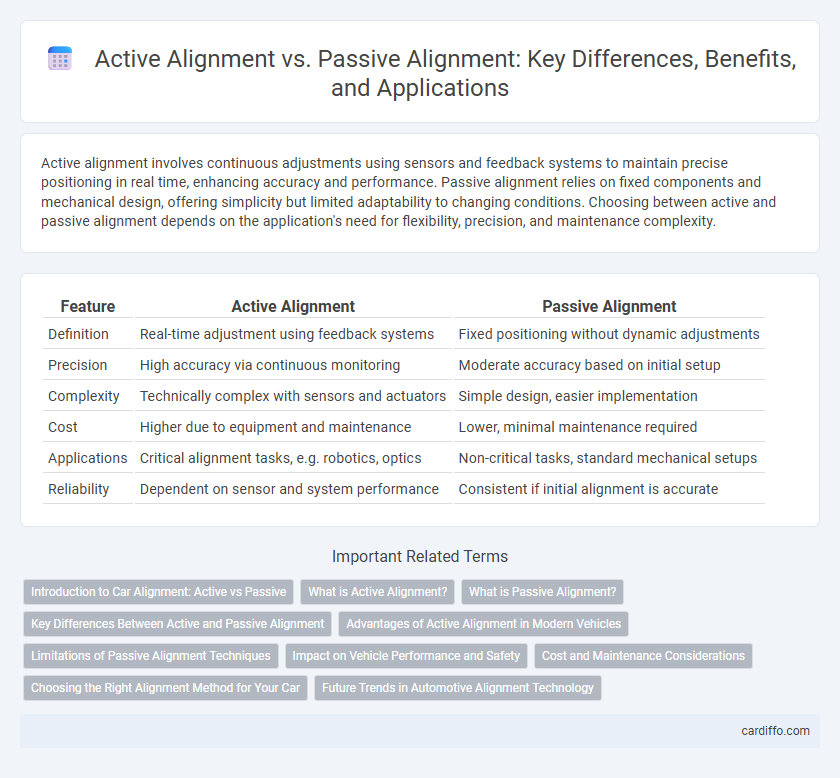

Table of Comparison

| Feature | Active Alignment | Passive Alignment |

|---|---|---|

| Definition | Real-time adjustment using feedback systems | Fixed positioning without dynamic adjustments |

| Precision | High accuracy via continuous monitoring | Moderate accuracy based on initial setup |

| Complexity | Technically complex with sensors and actuators | Simple design, easier implementation |

| Cost | Higher due to equipment and maintenance | Lower, minimal maintenance required |

| Applications | Critical alignment tasks, e.g. robotics, optics | Non-critical tasks, standard mechanical setups |

| Reliability | Dependent on sensor and system performance | Consistent if initial alignment is accurate |

Introduction to Car Alignment: Active vs Passive

Active alignment utilizes real-time sensor feedback and electronic adjustments to maintain optimal wheel positioning, enhancing vehicle stability and tire longevity. Passive alignment relies on fixed mechanical settings determined during initial setup or manual adjustments, which may degrade over time due to wear or road conditions. Understanding the distinction between active and passive alignment is crucial for optimizing handling performance and minimizing uneven tire wear.

What is Active Alignment?

Active alignment is a process where sensor feedback continuously guides real-time adjustments to maintain precise positioning between optical components. This method employs actuators and control systems to dynamically correct misalignments, ensuring optimal performance in complex optical assemblies. Active alignment enhances efficiency and accuracy compared to passive alignment, which relies solely on fixed mechanical positioning without feedback mechanisms.

What is Passive Alignment?

Passive alignment refers to a process in machinery and manufacturing where components naturally adjust to each other's positions without external forces or adjustments, relying on inherent material flexibility or design tolerances. This method contrasts with active alignment, which involves deliberate, controlled adjustments using sensors and actuators to achieve precise positioning. Passive alignment is commonly used in assembly lines and optical systems where cost-efficiency and simplicity are prioritized over ultra-precision.

Key Differences Between Active and Passive Alignment

Active alignment involves continuous, real-time adjustment using sensors and feedback mechanisms to maintain optimal positioning, enhancing system precision and responsiveness. Passive alignment relies on fixed components and pre-set adjustments without ongoing corrections, resulting in simplicity but less adaptability to dynamic changes. Key differences include responsiveness to external forces, complexity of implementation, and the degree of maintenance required to sustain alignment accuracy.

Advantages of Active Alignment in Modern Vehicles

Active alignment systems in modern vehicles provide continuous real-time adjustments that enhance handling precision and tire wear efficiency. By using sensors and actuators, active alignment optimizes steering response under various driving conditions, improving safety and performance. This technology reduces maintenance costs and energy consumption compared to passive alignment, which relies on fixed mechanical settings.

Limitations of Passive Alignment Techniques

Passive alignment techniques, commonly used in optical systems, rely on mechanical fixtures and tolerances without real-time adjustments, leading to limited precision and susceptibility to environmental variations such as temperature changes and vibrations. These constraints result in alignment drifts and reduced system performance over time, especially in applications demanding micrometer or sub-micrometer accuracy. The inability to dynamically correct misalignments restricts passive alignment's effectiveness in high-precision fields like fiber optics and photonics manufacturing.

Impact on Vehicle Performance and Safety

Active alignment systems continuously adjust wheel angles using sensors and actuators, enhancing vehicle handling, stability, and tire wear by maintaining optimal alignment under dynamic driving conditions. Passive alignment relies on fixed mechanical settings that can deteriorate over time, potentially causing uneven tire wear, reduced fuel efficiency, and compromised vehicle control. Active alignment technology significantly improves safety by adapting to road irregularities and driving behavior, reducing the risk of accidents compared to passive alignment.

Cost and Maintenance Considerations

Active alignment systems typically incur higher upfront costs due to advanced sensors and automated controls but reduce long-term maintenance expenses by continuously adjusting to operational changes, minimizing wear and tear. Passive alignment solutions offer lower initial investment and simpler installation but often require frequent manual adjustments and maintenance, leading to increased labor costs over time. Optimal alignment strategy depends on balancing initial budget constraints with anticipated maintenance demands and system reliability.

Choosing the Right Alignment Method for Your Car

Active alignment uses real-time sensors and computerized adjustments to maintain precise wheel angles, ideal for vehicles requiring dynamic tuning and optimal handling performance. Passive alignment relies on manual adjustments and fixed reference points, suitable for routine maintenance and vehicles with stable suspension setups. Selecting the right alignment method depends on factors such as vehicle type, driving conditions, and desired accuracy, with active alignment offering superior precision for performance cars and passive alignment providing cost-effective solutions for everyday driving.

Future Trends in Automotive Alignment Technology

Future trends in automotive alignment technology emphasize the shift from passive alignment systems, which rely on static reference points and manual adjustments, to active alignment systems utilizing real-time data and automated sensors for precision. Advanced driver-assistance systems (ADAS) integration demands dynamic alignment solutions that continuously monitor and adjust wheel angles to maintain optimal vehicle handling and safety. Machine learning algorithms and vehicle-to-infrastructure communication are expected to further enhance active alignment capabilities, enabling proactive maintenance and improved driving performance.

Active Alignment vs Passive Alignment Infographic

cardiffo.com

cardiffo.com