Alignment racks provide a stable and sturdy platform for precise wheel alignment by securely positioning the vehicle, while turn plates offer controlled wheel rotation to measure caster, camber, and toe angles accurately. Turn plates enhance the alignment process by allowing smooth movement of the wheels during adjustments, reducing friction and ensuring more accurate readings. Using both tools together optimizes alignment accuracy and improves vehicle handling and tire wear.

Table of Comparison

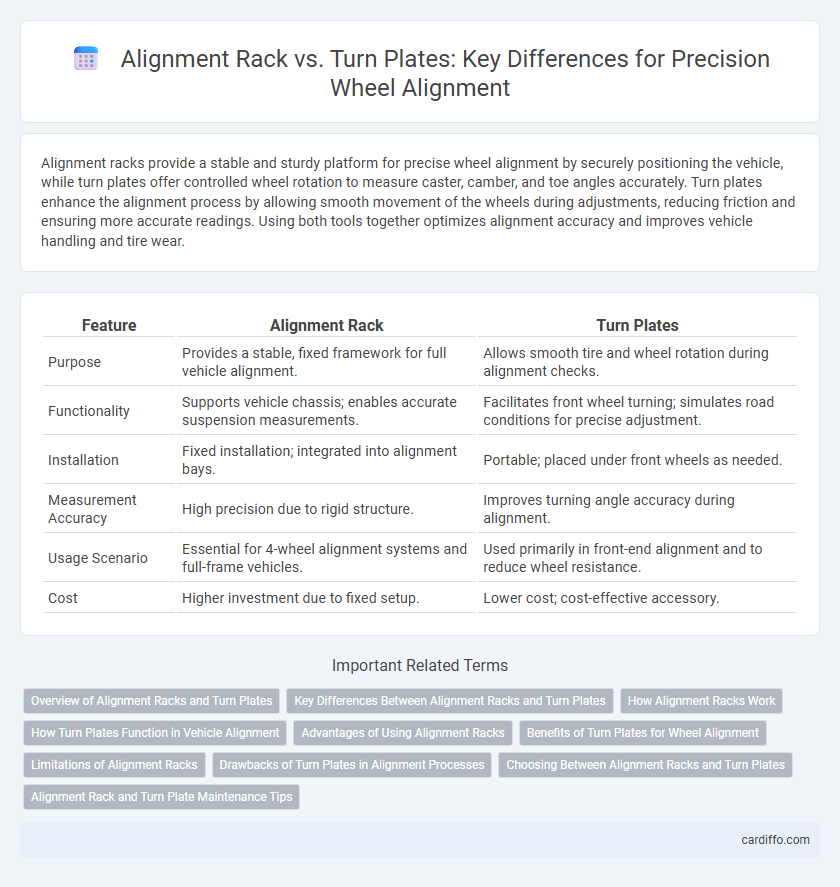

| Feature | Alignment Rack | Turn Plates |

|---|---|---|

| Purpose | Provides a stable, fixed framework for full vehicle alignment. | Allows smooth tire and wheel rotation during alignment checks. |

| Functionality | Supports vehicle chassis; enables accurate suspension measurements. | Facilitates front wheel turning; simulates road conditions for precise adjustment. |

| Installation | Fixed installation; integrated into alignment bays. | Portable; placed under front wheels as needed. |

| Measurement Accuracy | High precision due to rigid structure. | Improves turning angle accuracy during alignment. |

| Usage Scenario | Essential for 4-wheel alignment systems and full-frame vehicles. | Used primarily in front-end alignment and to reduce wheel resistance. |

| Cost | Higher investment due to fixed setup. | Lower cost; cost-effective accessory. |

Overview of Alignment Racks and Turn Plates

Alignment racks provide a stable, flat surface essential for accurate vehicle frame measurements and adjustments, facilitating efficient repair and realignment processes. Turn plates, installed at wheel positions, enable smooth rotation and precise steering angle adjustments by reducing friction during alignment procedures. Together, these tools optimize alignment accuracy, enhancing vehicle safety and performance.

Key Differences Between Alignment Racks and Turn Plates

Alignment racks provide a stable platform for precise vehicle positioning during wheel alignment, featuring built-in sensors and measuring systems that track suspension angles. Turn plates, placed under the front wheels, specifically allow smooth and accurate rotation of the wheels to measure steering angles and toe settings. While alignment racks offer comprehensive vehicle support and integrated measurement, turn plates focus on facilitating wheel movement and angle adjustments during the alignment process.

How Alignment Racks Work

Alignment racks function by securely positioning the vehicle using hydraulic or mechanical lifts, allowing precise measurements of the wheel alignment angles such as camber, caster, and toe. Reflectors or sensors attached to the wheels communicate with scanners or cameras mounted on the rack, providing accurate data for computer systems to analyze and adjust suspension components. This process ensures optimal tire contact with the road, improving vehicle handling, fuel efficiency, and tire longevity.

How Turn Plates Function in Vehicle Alignment

Turn plates function by allowing a vehicle's wheels to rotate freely during alignment procedures, reducing friction and enabling precise angle adjustments. These plates are placed under the front wheels to measure and adjust toe, camber, and caster angles accurately. Their smooth rotation and load-bearing capacity ensure the alignment system captures exact wheel positioning for optimal vehicle handling and tire wear.

Advantages of Using Alignment Racks

Alignment racks provide a stable and precise platform for vehicle suspension measurements, minimizing errors caused by uneven surfaces. They enhance the efficiency of wheel alignment by facilitating quicker and more accurate adjustments compared to turn plates, which primarily assist with steering angle measurements. Using alignment racks ensures comprehensive alignment data, leading to improved vehicle handling and tire longevity.

Benefits of Turn Plates for Wheel Alignment

Turn plates enhance wheel alignment accuracy by allowing precise measurement of tire movement during steering adjustments, reducing alignment errors. They minimize friction between the tires and the floor, enabling smoother and more consistent rotation for improved suspension calibration. Using turn plates leads to faster, more efficient alignment procedures, saving time and improving overall vehicle handling performance.

Limitations of Alignment Racks

Alignment racks have limitations including reduced accuracy on uneven surfaces, as slight floor irregularities can cause misalignment readings. They typically require substantial space, making them less practical for smaller workshops or mobile use. Compared to turn plates, alignment racks lack the ability to easily simulate wheel rotation dynamics, limiting precise measurement of steering axis inclination and caster angles.

Drawbacks of Turn Plates in Alignment Processes

Turn plates in alignment processes often pose drawbacks such as limited load capacity and potential inaccuracies due to uneven surface contact, which can affect the precision of vehicle positioning. Their fixed rotational points may restrict movement flexibility, making fine-tuning alignment adjustments challenging. Furthermore, turn plates typically require additional maintenance to ensure smooth operation, increasing downtime during alignment procedures.

Choosing Between Alignment Racks and Turn Plates

Choosing between alignment racks and turn plates depends on the specific needs of the vehicle alignment process. Alignment racks provide a stable platform for accurate measurements and adjustments, optimizing lift capabilities and vehicle positioning. Turn plates enhance wheel movement measurement by allowing precise tracking of steering angles and suspension response, making them essential for detailed alignment diagnostics.

Alignment Rack and Turn Plate Maintenance Tips

Proper maintenance of alignment racks ensures precise vehicle positioning and prolongs equipment lifespan by regularly calibrating sensors and checking hydraulic components. Turn plates require consistent lubrication, inspection for wear, and calibration to maintain accurate wheel rotation during alignment procedures. Combining routine maintenance of both alignment racks and turn plates minimizes measurement errors and enhances shop efficiency.

Alignment Rack vs Turn Plates Infographic

cardiffo.com

cardiffo.com