Static alignment involves measuring a vehicle's wheel positions when it is stationary, ensuring proper angles like camber, caster, and toe for optimal tire wear and handling. Dynamic alignment adjusts these parameters while the vehicle is in motion, accounting for real-world driving conditions to enhance steering response and stability. Choosing between static and dynamic alignment depends on the specific needs for precision in performance and everyday driving comfort.

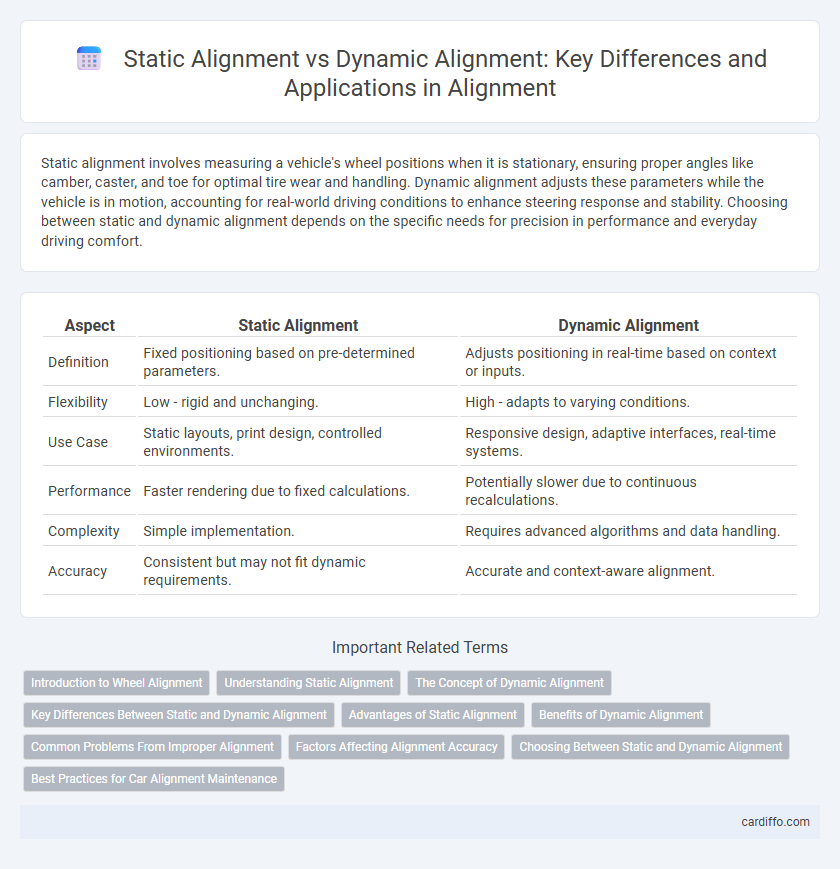

Table of Comparison

| Aspect | Static Alignment | Dynamic Alignment |

|---|---|---|

| Definition | Fixed positioning based on pre-determined parameters. | Adjusts positioning in real-time based on context or inputs. |

| Flexibility | Low - rigid and unchanging. | High - adapts to varying conditions. |

| Use Case | Static layouts, print design, controlled environments. | Responsive design, adaptive interfaces, real-time systems. |

| Performance | Faster rendering due to fixed calculations. | Potentially slower due to continuous recalculations. |

| Complexity | Simple implementation. | Requires advanced algorithms and data handling. |

| Accuracy | Consistent but may not fit dynamic requirements. | Accurate and context-aware alignment. |

Introduction to Wheel Alignment

Wheel alignment ensures vehicle wheels are set to the optimum position relative to each other and the road, enhancing tire longevity and handling performance. Static alignment involves adjusting the wheels when the vehicle is stationary, focusing on camber, caster, and toe angles at rest. Dynamic alignment considers these same angles during actual driving conditions, accounting for forces and suspension movement to achieve precise handling and stability.

Understanding Static Alignment

Static alignment refers to the precise positioning and orientation of components or systems when they are stationary, ensuring they remain properly aligned without movement or load. It involves measurements and adjustments conducted in a controlled environment, often using laser alignment tools, dial indicators, or optical systems to achieve accurate positioning. Understanding static alignment is crucial for maintaining machine longevity, preventing premature wear, and ensuring optimal performance before dynamic forces come into play.

The Concept of Dynamic Alignment

Dynamic alignment emphasizes real-time adjustments of body positioning to optimize movement efficiency and reduce strain, contrasting with static alignment that focuses on fixed postural positioning. It integrates proprioception and muscular engagement to adapt to varying physical demands, enhancing functional performance and injury prevention. This concept is essential in disciplines such as physical therapy, sports training, and ergonomics, where movement fluidity and adaptability are prioritized.

Key Differences Between Static and Dynamic Alignment

Static alignment refers to the fixed positioning of body segments in a neutral posture without movement, primarily assessed through static poses or images. Dynamic alignment involves the continuous adjustment and coordination of body parts during movement, emphasizing optimal biomechanics in real-time activities. Key differences between static and dynamic alignment include the assessment method--static uses stationary positions while dynamic is movement-based--and the application, where static alignment provides baseline structural analysis, and dynamic alignment offers insights into functional performance and injury prevention.

Advantages of Static Alignment

Static alignment provides consistent positioning that enhances structural stability and minimizes wear on mechanical components. It allows precise calibration without the variability introduced by movement, ensuring reliable operation in fixed systems. This type of alignment is ideal for applications requiring unwavering accuracy and reduced maintenance frequency.

Benefits of Dynamic Alignment

Dynamic alignment enhances performance by allowing continuous real-time adjustments that improve movement efficiency and reduce injury risk. It supports natural biomechanics by adapting joint positioning and muscle activation during activity, leading to better balance and stability. Athletes and individuals experience increased flexibility and longevity in physical function through the personalized responsiveness of dynamic alignment systems.

Common Problems From Improper Alignment

Improper static alignment often leads to uneven wear on joints and ligaments, resulting in chronic pain and increased risk of osteoarthritis. Dynamic misalignment during movement can cause muscle imbalances, decreased efficiency, and higher susceptibility to injuries such as strains or tendonitis. Both alignment issues compromise overall biomechanics, affecting posture, gait, and long-term musculoskeletal health.

Factors Affecting Alignment Accuracy

Static alignment accuracy depends heavily on precise sensor calibration, consistent environmental conditions, and rigid mechanical structures that minimize movement during measurement. Dynamic alignment accuracy, however, is influenced by factors such as real-time motion compensation algorithms, sensor fusion quality, and latency in data processing to handle changing positions and velocities. Both alignment types require robust error correction techniques and high-resolution measurement tools to optimize overall system performance.

Choosing Between Static and Dynamic Alignment

Choosing between static and dynamic alignment depends on the specific use case, performance requirements, and system constraints. Static alignment offers faster access and predictable memory layout by fixing data alignment at compile-time, ideal for embedded systems and real-time applications. Dynamic alignment provides flexibility with runtime adaptation to varying data sizes and architectures, suitable for systems requiring interoperability and dynamic memory management.

Best Practices for Car Alignment Maintenance

Static alignment involves adjusting the vehicle's wheels while the car is stationary, ensuring proper camber, caster, and toe angles based on factory specifications. Dynamic alignment measures and corrects wheel angles while the vehicle is in motion, addressing real-world driving conditions and suspension behavior. For optimal car alignment maintenance, regularly inspect suspension components, avoid sudden impacts, and perform alignment checks every 12,000 miles or after significant repairs.

Static alignment vs dynamic alignment Infographic

cardiffo.com

cardiffo.com