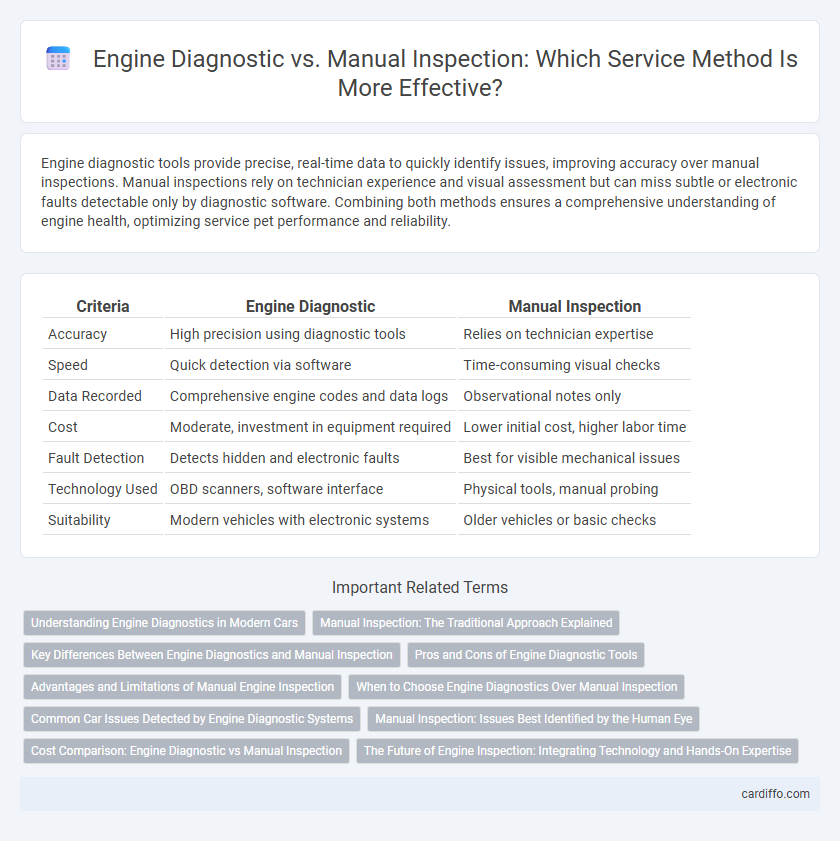

Engine diagnostic tools provide precise, real-time data to quickly identify issues, improving accuracy over manual inspections. Manual inspections rely on technician experience and visual assessment but can miss subtle or electronic faults detectable only by diagnostic software. Combining both methods ensures a comprehensive understanding of engine health, optimizing service pet performance and reliability.

Table of Comparison

| Criteria | Engine Diagnostic | Manual Inspection |

|---|---|---|

| Accuracy | High precision using diagnostic tools | Relies on technician expertise |

| Speed | Quick detection via software | Time-consuming visual checks |

| Data Recorded | Comprehensive engine codes and data logs | Observational notes only |

| Cost | Moderate, investment in equipment required | Lower initial cost, higher labor time |

| Fault Detection | Detects hidden and electronic faults | Best for visible mechanical issues |

| Technology Used | OBD scanners, software interface | Physical tools, manual probing |

| Suitability | Modern vehicles with electronic systems | Older vehicles or basic checks |

Understanding Engine Diagnostics in Modern Cars

Engine diagnostics in modern cars utilize advanced computer systems to monitor and analyze vehicle performance, identifying issues with precision through onboard sensors and diagnostic tools. This technology provides real-time data on engine functions, enabling quicker problem detection compared to traditional manual inspections. By accessing detailed error codes and performance metrics, engine diagnostics improve maintenance accuracy and reduce repair times.

Manual Inspection: The Traditional Approach Explained

Manual inspection remains a fundamental component of engine diagnostics, relying on skilled technicians to identify issues through direct visual and tactile examination. This traditional approach allows for the detection of subtle mechanical problems and irregularities that automated tools might overlook. Emphasizing hands-on assessment, manual inspection supports comprehensive engine care by evaluating components such as belts, hoses, and fluid levels in real time.

Key Differences Between Engine Diagnostics and Manual Inspection

Engine diagnostics utilizes advanced computerized tools to detect and analyze engine faults with high accuracy, offering real-time data and error codes. Manual inspection relies on physical examination and experience-based assessments, making it useful for identifying visible issues but less effective for complex internal problems. The key difference lies in diagnostics providing precise, data-driven insights, whereas manual inspection depends on visual and tactile evaluation.

Pros and Cons of Engine Diagnostic Tools

Engine diagnostic tools provide precise, real-time data by interfacing directly with the vehicle's onboard computer system, allowing for faster identification of issues compared to manual inspection. However, they can be limited by software compatibility and may not detect physical wear or subtle mechanical problems that a hands-on manual inspection can reveal. Investing in both methods ensures comprehensive engine health assessment, balancing technological accuracy with tactile expertise.

Advantages and Limitations of Manual Engine Inspection

Manual engine inspection offers the advantage of direct human assessment, allowing technicians to identify subtle issues like unusual noises or smells that diagnostic tools may miss. This method requires skilled expertise and can be time-consuming, limiting its efficiency for complex engine systems. However, manual inspection remains essential for detecting physical wear, leaks, and visual damage that automated diagnostics might overlook.

When to Choose Engine Diagnostics Over Manual Inspection

Engine diagnostics should be chosen over manual inspection when precise fault detection and real-time data analysis are critical for accurate assessment and efficient repair. Advanced diagnostic tools rapidly identify error codes and sensor malfunctions that may be invisible during manual inspection, reducing downtime and repair costs. This method is particularly effective for complex engine systems equipped with modern electronic control units (ECUs) requiring specialized software to interpret performance metrics.

Common Car Issues Detected by Engine Diagnostic Systems

Engine diagnostic systems swiftly identify common car issues such as faulty oxygen sensors, misfiring cylinders, and malfunctioning catalytic converters by analyzing real-time data from the vehicle's onboard computer. These systems detect problems related to engine performance, emissions, and fuel efficiency more accurately than manual inspections, which rely heavily on visual checks and mechanic experience. Early detection through engine diagnostics reduces repair costs and prevents breakdowns by addressing underlying issues before they escalate.

Manual Inspection: Issues Best Identified by the Human Eye

Manual inspection excels at identifying subtle visual issues such as hairline cracks, corrosion, and fluid leaks that engine diagnostics may overlook. Human inspectors can detect irregular wear patterns, loose connections, and unusual odors, providing insights beyond electronic sensor data. This hands-on approach ensures a comprehensive assessment of the engine's condition, complementing diagnostic tool findings.

Cost Comparison: Engine Diagnostic vs Manual Inspection

Engine diagnostic tools provide a cost-effective solution by quickly identifying faults, reducing labor hours and minimizing the risk of overlooked issues compared to manual inspection. Manual inspection often incurs higher labor costs due to its time-intensive nature and reliance on technician experience, potentially leading to missed or misdiagnosed problems. Investing in engine diagnostics lowers overall service expenses by streamlining the repair process and preventing costly engine damage.

The Future of Engine Inspection: Integrating Technology and Hands-On Expertise

Engine diagnostic technology enhances accuracy and efficiency by utilizing advanced sensors and real-time data analytics, reducing human error in engine inspection. Manual inspection remains critical for detecting subtle physical issues and interpreting complex mechanical nuances that technology may miss. Integrating both methods leverages cutting-edge diagnostics with skilled hands-on expertise, driving the future of comprehensive engine maintenance and reliability.

Engine Diagnostic vs Manual Inspection Infographic

cardiffo.com

cardiffo.com