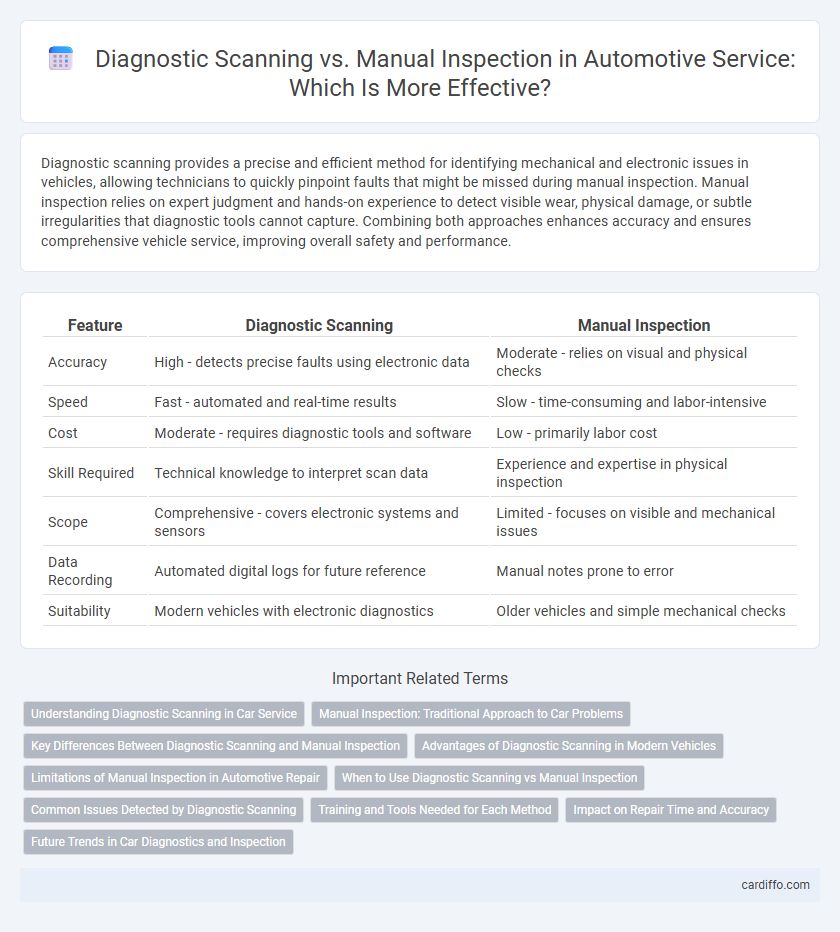

Diagnostic scanning provides a precise and efficient method for identifying mechanical and electronic issues in vehicles, allowing technicians to quickly pinpoint faults that might be missed during manual inspection. Manual inspection relies on expert judgment and hands-on experience to detect visible wear, physical damage, or subtle irregularities that diagnostic tools cannot capture. Combining both approaches enhances accuracy and ensures comprehensive vehicle service, improving overall safety and performance.

Table of Comparison

| Feature | Diagnostic Scanning | Manual Inspection |

|---|---|---|

| Accuracy | High - detects precise faults using electronic data | Moderate - relies on visual and physical checks |

| Speed | Fast - automated and real-time results | Slow - time-consuming and labor-intensive |

| Cost | Moderate - requires diagnostic tools and software | Low - primarily labor cost |

| Skill Required | Technical knowledge to interpret scan data | Experience and expertise in physical inspection |

| Scope | Comprehensive - covers electronic systems and sensors | Limited - focuses on visible and mechanical issues |

| Data Recording | Automated digital logs for future reference | Manual notes prone to error |

| Suitability | Modern vehicles with electronic diagnostics | Older vehicles and simple mechanical checks |

Understanding Diagnostic Scanning in Car Service

Diagnostic scanning in car service utilizes advanced onboard computer systems to identify error codes and system malfunctions quickly and accurately. This technology provides detailed insights into engine performance, transmission issues, and electronic system faults that manual inspection might overlook. By pinpointing exact problems, diagnostic scanning enhances repair precision, reduces labor time, and improves vehicle reliability.

Manual Inspection: Traditional Approach to Car Problems

Manual inspection remains a crucial service method for diagnosing car problems by relying on an experienced technician's expertise to identify issues through physical examination and testing. This traditional approach allows for detecting subtle symptoms, such as unusual noises or smells, that diagnostic scanning tools might miss. Despite advances in digital diagnostics, manual inspection continues to provide personalized and comprehensive assessment, especially for older vehicles with complex mechanical systems.

Key Differences Between Diagnostic Scanning and Manual Inspection

Diagnostic scanning employs advanced electronic tools to quickly detect faults by interfacing with a vehicle's onboard computer systems, providing precise error codes and real-time data analysis. Manual inspection relies on a technician's hands-on examination, visual checks, and sensory evaluation to identify visible or physical issues that may not trigger electronic alerts. While diagnostic scanning enhances speed and accuracy through technology, manual inspection delivers thorough, context-driven evaluation for complex or subtle problems.

Advantages of Diagnostic Scanning in Modern Vehicles

Diagnostic scanning offers precise fault detection and real-time data analysis, enabling quicker identification of vehicle issues compared to manual inspection. Modern vehicles equipped with complex electronic systems benefit from scanning tools that access onboard computer modules, providing detailed error codes and performance metrics. This technology reduces diagnostic time, increases accuracy, and supports preventative maintenance, enhancing overall vehicle reliability and service efficiency.

Limitations of Manual Inspection in Automotive Repair

Manual inspection in automotive repair often misses hidden faults due to its reliance on visual and tactile evaluation without advanced tools. Diagnostic scanning uses electronic data from onboard sensors to detect issues that are invisible during a surface-level inspection. Limitations of manual inspection include human error, inability to access complex systems, and lack of real-time data analysis, which delays accurate troubleshooting and increases repair time.

When to Use Diagnostic Scanning vs Manual Inspection

Diagnostic scanning excels in quickly identifying electronic and software-related issues within complex systems, making it ideal for modern vehicles and machinery equipped with onboard computers. Manual inspection proves essential for detecting physical wear, corrosion, or mechanical faults that diagnostic tools cannot sense, often serving as a complementary technique to scanning. Use diagnostic scanning for initial troubleshooting and data retrieval, then apply manual inspection to verify findings and assess components that require tactile evaluation.

Common Issues Detected by Diagnostic Scanning

Diagnostic scanning effectively detects common vehicle issues such as engine misfires, faulty oxygen sensors, and transmission malfunctions by analyzing error codes from the onboard computer system. This method identifies problems like misconfigured fuel injectors, sensor failures, and emission control issues faster than manual inspection. Early detection through diagnostic scanning prevents costly repairs and enhances overall vehicle performance.

Training and Tools Needed for Each Method

Diagnostic scanning requires specialized training in electronic diagnostic systems and proficiency with advanced scanning tools such as OBD-II scanners, multimeters, and software interfaces for accurate fault detection. Manual inspection demands extensive hands-on experience and knowledge of mechanical systems, along with essential tools like wrenches, screwdrivers, and inspection mirrors to identify physical wear and damage. Both methods benefit from ongoing training to stay updated with evolving automotive technologies and maintain diagnostic accuracy.

Impact on Repair Time and Accuracy

Diagnostic scanning significantly reduces repair time by quickly identifying fault codes that pinpoint specific issues, enhancing accuracy compared to manual inspection. Manual inspection, while useful for detecting physical damage or wear, often requires more time and carries a higher risk of human error, potentially leading to misdiagnosis. Integrating diagnostic scanning with manual inspection ensures comprehensive analysis, optimizing both repair speed and accuracy.

Future Trends in Car Diagnostics and Inspection

Future trends in car diagnostics emphasize the integration of advanced diagnostic scanning technologies that enable real-time data analysis, predictive maintenance, and enhanced fault detection accuracy. Manual inspection remains essential for complex, tactile assessments, but it is increasingly supplemented by machine learning algorithms and IoT-connected sensors that streamline diagnostics. Automotive service providers are adopting AI-driven platforms and augmented reality tools to improve diagnostic efficiency and reduce vehicle downtime.

Diagnostic Scanning vs Manual Inspection Infographic

cardiffo.com

cardiffo.com