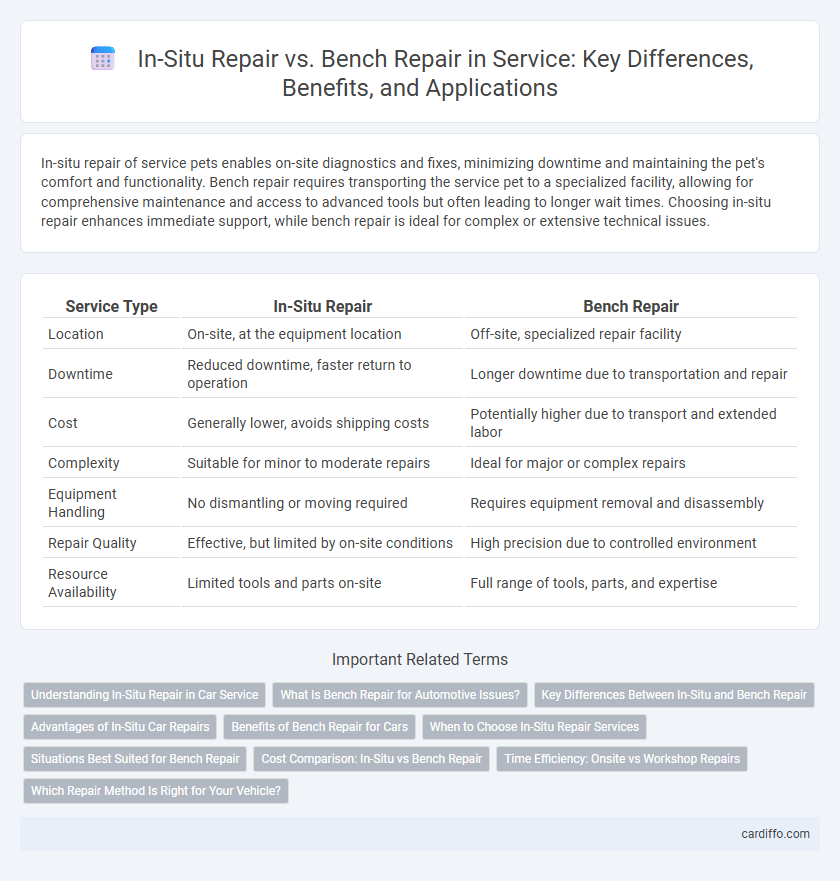

In-situ repair of service pets enables on-site diagnostics and fixes, minimizing downtime and maintaining the pet's comfort and functionality. Bench repair requires transporting the service pet to a specialized facility, allowing for comprehensive maintenance and access to advanced tools but often leading to longer wait times. Choosing in-situ repair enhances immediate support, while bench repair is ideal for complex or extensive technical issues.

Table of Comparison

| Service Type | In-Situ Repair | Bench Repair |

|---|---|---|

| Location | On-site, at the equipment location | Off-site, specialized repair facility |

| Downtime | Reduced downtime, faster return to operation | Longer downtime due to transportation and repair |

| Cost | Generally lower, avoids shipping costs | Potentially higher due to transport and extended labor |

| Complexity | Suitable for minor to moderate repairs | Ideal for major or complex repairs |

| Equipment Handling | No dismantling or moving required | Requires equipment removal and disassembly |

| Repair Quality | Effective, but limited by on-site conditions | High precision due to controlled environment |

| Resource Availability | Limited tools and parts on-site | Full range of tools, parts, and expertise |

Understanding In-Situ Repair in Car Service

In-situ repair in car service enables technicians to fix vehicle components directly at their installed location, reducing downtime and avoiding the costs associated with part removal and transportation to a workshop. This method often utilizes advanced diagnostic tools and mobile repair units to address issues efficiently on-site. Compared to bench repair, in-situ repair enhances service speed and convenience, particularly for large or complex assemblies like transmissions or engine parts that are difficult to disassemble.

What Is Bench Repair for Automotive Issues?

Bench repair in automotive service involves disassembling and fixing vehicle components at a specialized workstation, allowing technicians to address complex mechanical or electrical issues in a controlled environment. This method ensures precise diagnostics, thorough cleaning, and the use of specialized tools to restore parts like alternators, starters, and fuel injectors to optimal function. Bench repair is essential for components that require detailed inspection or cannot be efficiently repaired on-site through in-situ methods.

Key Differences Between In-Situ and Bench Repair

In-situ repair involves fixing equipment directly at its operational location, minimizing downtime and transportation costs, while bench repair requires moving the equipment to a specialized facility for comprehensive diagnostics and restoration. In-situ repair is ideal for minor issues and maintenance tasks, allowing immediate intervention with limited resources. Bench repair suits complex failures needing advanced tools and detailed inspection, offering thorough restoration but with extended repair time and logistical considerations.

Advantages of In-Situ Car Repairs

In-situ car repairs offer significant advantages by eliminating the need to transport vehicles to service centers, reducing downtime and associated costs. This approach enables technicians to diagnose and fix issues directly at the vehicle's location, ensuring faster turnaround and minimizing disruption to the owner. Enhanced convenience and immediate access to the vehicle's environment often lead to more accurate repairs and improved customer satisfaction.

Benefits of Bench Repair for Cars

Bench repair for cars provides precise diagnostics and controlled conditions unavailable in in-situ repair, ensuring higher accuracy in identifying and resolving complex issues. Technicians benefit from specialized tools and equipment on the bench, leading to enhanced repair quality and extended component lifespan. This method reduces vehicle downtime by streamlining the repair process and minimizing repeat visits, resulting in increased customer satisfaction and cost efficiency.

When to Choose In-Situ Repair Services

In-situ repair services are ideal when equipment downtime must be minimized and immediate restoration is critical for operational continuity. This method is preferable for large, immovable systems or components that are costly and time-consuming to disassemble and transport to a repair bench. Choosing in-situ repair reduces logistical challenges and accelerates service response, especially in industries like manufacturing, energy, and aerospace where prolonged outages can lead to significant losses.

Situations Best Suited for Bench Repair

Bench repair is best suited for complex component failures that require detailed diagnostics and precision tools unavailable on-site, such as electronic circuit board refurbishing or intricate mechanical part replacements. Situations involving heavy or bulky equipment that cannot be easily transported benefit from in-situ repair, but smaller, delicate parts typically yield better quality and reliability outcomes when serviced in a controlled bench environment. Bench repair also allows for extensive testing and calibration under standardized conditions, ensuring optimal performance post-repair.

Cost Comparison: In-Situ vs Bench Repair

In-situ repair significantly reduces labor and transportation costs by eliminating the need to dismantle and move equipment to off-site facilities. Bench repair may incur higher expenses due to additional handling, shipping, and extended downtime impacting operational productivity. Cost analysis consistently favors in-situ methods for large-scale or critical systems where minimizing service interruption is essential.

Time Efficiency: Onsite vs Workshop Repairs

In-situ repair significantly reduces downtime by eliminating the need to transport equipment to the workshop, enabling immediate troubleshooting and restoration. Workshop repairs, while often allowing for more comprehensive diagnostics, involve additional time for disassembly, shipping, and reassembly, leading to extended operational interruptions. Prioritizing onsite repairs enhances time efficiency, crucial for industries requiring continuous or rapid equipment availability.

Which Repair Method Is Right for Your Vehicle?

In-situ repair offers the advantage of fixing your vehicle directly at its location, minimizing downtime and transportation costs, ideal for minor to moderate damages. Bench repair, performed in a dedicated facility, ensures comprehensive diagnostics and access to specialized tools, making it suitable for extensive or complex repairs. The choice depends on damage severity, repair complexity, and urgency, with in-situ favored for quick fixes and bench repair preferred for thorough restoration.

in-situ repair vs bench repair Infographic

cardiffo.com

cardiffo.com