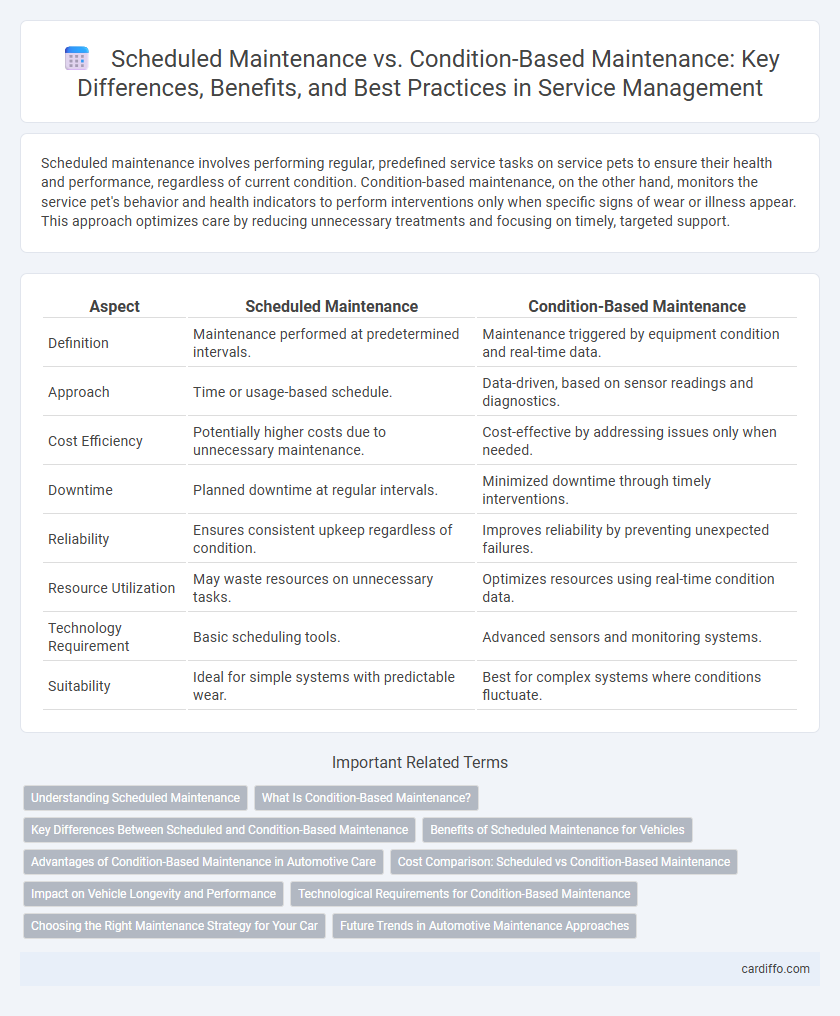

Scheduled maintenance involves performing regular, predefined service tasks on service pets to ensure their health and performance, regardless of current condition. Condition-based maintenance, on the other hand, monitors the service pet's behavior and health indicators to perform interventions only when specific signs of wear or illness appear. This approach optimizes care by reducing unnecessary treatments and focusing on timely, targeted support.

Table of Comparison

| Aspect | Scheduled Maintenance | Condition-Based Maintenance |

|---|---|---|

| Definition | Maintenance performed at predetermined intervals. | Maintenance triggered by equipment condition and real-time data. |

| Approach | Time or usage-based schedule. | Data-driven, based on sensor readings and diagnostics. |

| Cost Efficiency | Potentially higher costs due to unnecessary maintenance. | Cost-effective by addressing issues only when needed. |

| Downtime | Planned downtime at regular intervals. | Minimized downtime through timely interventions. |

| Reliability | Ensures consistent upkeep regardless of condition. | Improves reliability by preventing unexpected failures. |

| Resource Utilization | May waste resources on unnecessary tasks. | Optimizes resources using real-time condition data. |

| Technology Requirement | Basic scheduling tools. | Advanced sensors and monitoring systems. |

| Suitability | Ideal for simple systems with predictable wear. | Best for complex systems where conditions fluctuate. |

Understanding Scheduled Maintenance

Scheduled maintenance involves performing predefined service tasks at regular, fixed intervals, based on time or usage metrics, to prevent equipment failure and extend asset life. This proactive approach relies on manufacturer recommendations and historical data to ensure consistent reliability and reduce unexpected downtime. By adhering to a strict maintenance calendar, organizations optimize resource allocation and maintain operational efficiency.

What Is Condition-Based Maintenance?

Condition-based maintenance (CBM) monitors real-time equipment data using sensors and diagnostic tools to predict and address issues before failure occurs. Unlike scheduled maintenance, which follows fixed intervals, CBM optimizes service timing based on actual equipment condition, reducing downtime and repair costs. Implementing CBM enhances operational efficiency and extends asset lifespan by targeting maintenance precisely when needed.

Key Differences Between Scheduled and Condition-Based Maintenance

Scheduled maintenance occurs at predetermined intervals regardless of equipment condition, ensuring routine servicing to prevent unexpected failures. Condition-based maintenance relies on real-time data and sensor monitoring to perform repairs only when specific wear or fault indicators are detected. The key difference lies in the proactive, time-driven approach of scheduled maintenance versus the reactive, data-driven strategy of condition-based maintenance, optimizing resource allocation and minimizing downtime.

Benefits of Scheduled Maintenance for Vehicles

Scheduled maintenance for vehicles ensures consistent performance and minimizes unexpected breakdowns by adhering to manufacturer-recommended service intervals. It helps in maintaining warranty validity and optimizing fuel efficiency through regular inspections and timely replacement of critical components. This proactive approach extends vehicle lifespan and enhances safety by addressing potential issues before they escalate.

Advantages of Condition-Based Maintenance in Automotive Care

Condition-based maintenance in automotive care optimizes vehicle performance by using real-time data and sensor technology to predict component wear, reducing unnecessary servicing and preventing unexpected breakdowns. This approach extends equipment lifespan and lowers maintenance costs while enhancing safety by addressing issues precisely when needed. Maintenance efficiency improves through targeted interventions that minimize downtime and preserve vehicle reliability.

Cost Comparison: Scheduled vs Condition-Based Maintenance

Scheduled maintenance involves fixed intervals for inspections and part replacements, often leading to unnecessary labor and parts costs when equipment is still functioning well. Condition-based maintenance relies on real-time data and sensor monitoring to perform maintenance only when equipment shows signs of wear or impending failure, significantly reducing downtime and associated repair expenses. Overall, condition-based maintenance tends to optimize costs by minimizing both labor and material waste compared to the routine expenses incurred in scheduled maintenance.

Impact on Vehicle Longevity and Performance

Scheduled maintenance follows a fixed timeline for servicing vehicles, ensuring consistent upkeep but potentially replacing parts before necessary, which may lead to higher costs. Condition-based maintenance relies on real-time data and diagnostics to address issues only when performance metrics indicate wear or failure risk, enhancing vehicle longevity by minimizing unnecessary interventions. Implementing condition-based maintenance optimizes vehicle performance and extends lifespan through targeted, data-driven service actions.

Technological Requirements for Condition-Based Maintenance

Condition-based maintenance relies on real-time data collection through sensors, IoT devices, and advanced analytics platforms to monitor asset health continuously. Integrating machine learning algorithms and predictive modeling enables accurate failure predictions and optimized maintenance scheduling. Implementing cloud computing infrastructure ensures scalable data storage and processing capabilities critical for effective condition-based maintenance systems.

Choosing the Right Maintenance Strategy for Your Car

Scheduled maintenance involves performing routine services at fixed intervals, ensuring consistent upkeep and reducing unexpected breakdowns. Condition-based maintenance relies on real-time data from sensors and diagnostics to address issues only when specific wear or performance thresholds are met, optimizing resource use and minimizing downtime. Selecting the right maintenance strategy for your car depends on factors like vehicle age, usage patterns, and available technology, with modern cars often benefiting from condition-based approaches for enhanced efficiency.

Future Trends in Automotive Maintenance Approaches

Scheduled maintenance remains a foundational approach in automotive service, relying on predetermined intervals to ensure vehicle reliability and safety. Condition-based maintenance is gaining traction through advanced sensor technologies and real-time data analytics, enabling proactive identification of potential component failures before they occur. Future trends point toward integrating AI-driven predictive maintenance systems that optimize service schedules, reduce downtime, and personalize vehicle care based on actual usage patterns.

Scheduled maintenance vs Condition-based maintenance Infographic

cardiffo.com

cardiffo.com