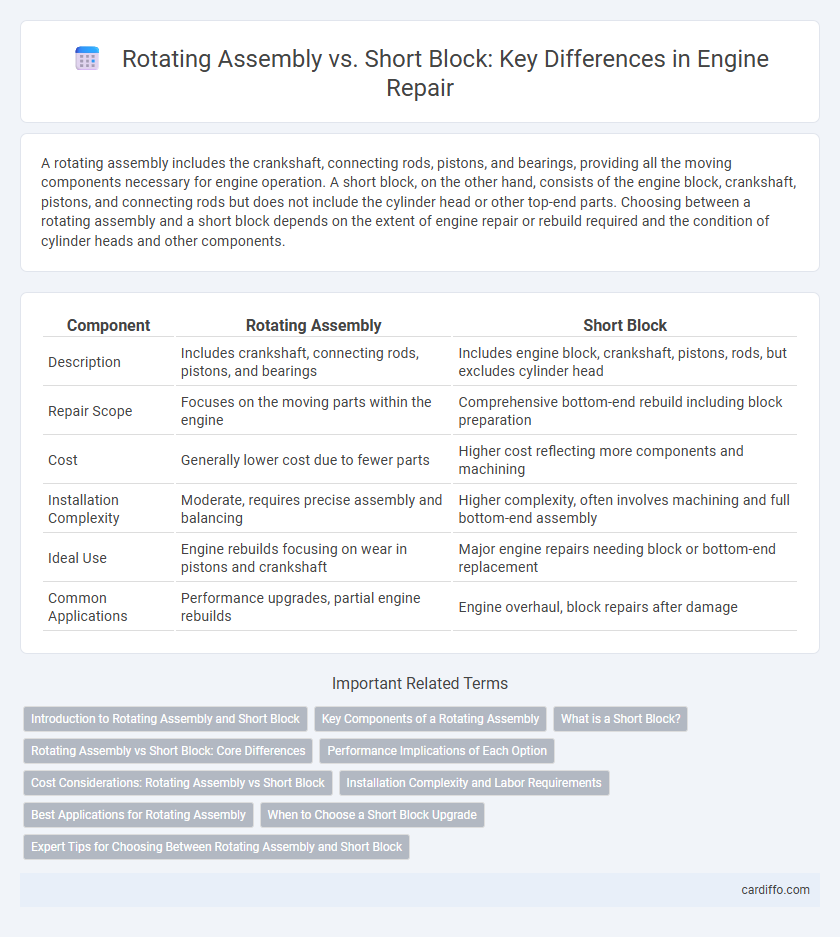

A rotating assembly includes the crankshaft, connecting rods, pistons, and bearings, providing all the moving components necessary for engine operation. A short block, on the other hand, consists of the engine block, crankshaft, pistons, and connecting rods but does not include the cylinder head or other top-end parts. Choosing between a rotating assembly and a short block depends on the extent of engine repair or rebuild required and the condition of cylinder heads and other components.

Table of Comparison

| Component | Rotating Assembly | Short Block |

|---|---|---|

| Description | Includes crankshaft, connecting rods, pistons, and bearings | Includes engine block, crankshaft, pistons, rods, but excludes cylinder head |

| Repair Scope | Focuses on the moving parts within the engine | Comprehensive bottom-end rebuild including block preparation |

| Cost | Generally lower cost due to fewer parts | Higher cost reflecting more components and machining |

| Installation Complexity | Moderate, requires precise assembly and balancing | Higher complexity, often involves machining and full bottom-end assembly |

| Ideal Use | Engine rebuilds focusing on wear in pistons and crankshaft | Major engine repairs needing block or bottom-end replacement |

| Common Applications | Performance upgrades, partial engine rebuilds | Engine overhaul, block repairs after damage |

Introduction to Rotating Assembly and Short Block

The rotating assembly consists of critical moving components such as the crankshaft, connecting rods, pistons, and bearings, essential for converting linear piston motion into rotational power. The short block includes the rotating assembly housed within the engine block, often paired with cylinder liners and a lubricated crankcase, serving as the foundation for engine rebuilds. Understanding these components is vital for precise engine repair and performance restoration.

Key Components of a Rotating Assembly

The rotating assembly in engine repair includes critical components such as the crankshaft, connecting rods, pistons, and main bearings, which work together to convert linear piston motion into rotational energy. Unlike a short block, which typically consists of the engine block, crankshaft, pistons, and camshaft without cylinder heads, the rotating assembly emphasizes moving parts essential for engine rotation and power generation. Precision balancing and component integrity within the rotating assembly are vital for reducing engine vibration and ensuring optimal performance during repair and rebuild.

What is a Short Block?

A short block is a partially assembled engine component that includes the engine block, crankshaft, connecting rods, and pistons, but excludes the cylinder head, valve train, and other external parts. It serves as a core foundation for engine repair or rebuilds, offering a cost-effective way to replace worn internal components without buying a fully assembled rotating assembly. Mechanics often choose a short block for its balance between completeness and customization during engine repairs.

Rotating Assembly vs Short Block: Core Differences

A rotating assembly includes essential moving components like the crankshaft, connecting rods, pistons, and sometimes the camshaft, providing a complete mechanical foundation for engine operation. In contrast, a short block primarily consists of the engine block, crankshaft, pistons, and connecting rods, but excludes the cylinder head and valvetrain, making it a more basic engine rebuild option. Choosing between a rotating assembly and a short block depends on the level of engine damage and repair needs, where a rotating assembly offers a more comprehensive upgrade to crucial moving parts while a short block focuses on core structural elements.

Performance Implications of Each Option

Choosing a rotating assembly over a short block significantly enhances engine performance due to its comprehensive inclusion of matched pistons, rods, and crankshaft, ensuring optimal balance and strength for high RPM operation. A short block, consisting primarily of the engine block and rotating assembly without the cylinder heads or valvetrain, offers less tuning flexibility and may limit peak horsepower and torque potential. Performance enthusiasts favor rotating assemblies for precision-engineered components that improve durability and allow customized upgrades tailored to aggressive driving or racing conditions.

Cost Considerations: Rotating Assembly vs Short Block

Rotating assemblies generally cost more than short blocks due to the inclusion of critical moving parts like the crankshaft, pistons, and rods, which require precise machining and balancing. Short blocks, consisting mainly of the engine block and rotating assembly components without the cylinder head, offer a more affordable repair option while still restoring core engine functionality. Choosing between the two depends on budget constraints and the extent of engine wear or damage, with rotating assemblies providing a comprehensive rebuild at a higher price point.

Installation Complexity and Labor Requirements

Rotating assembly installation demands precise alignment of components like the crankshaft, connecting rods, and pistons, resulting in higher labor intensity and specialized skill requirements compared to short block installation. Short block replacement involves fewer steps, primarily focusing on fitting a pre-assembled engine section, significantly reducing installation time and complexity. Technicians often prefer short block repairs for efficiency, while rotating assemblies require meticulous attention to detail to ensure engine balance and performance integrity.

Best Applications for Rotating Assembly

Rotating assemblies are best suited for engine rebuilds requiring precise balancing of the crankshaft, rods, and pistons to improve performance and reduce vibration. These assemblies are ideal for high-performance applications, where custom tuning and enhanced durability are essential. Using a rotating assembly allows mechanics to replace worn components without the need for a complete short block, optimizing cost-efficiency and engine lifespan.

When to Choose a Short Block Upgrade

A short block upgrade is ideal when the engine's internal components such as pistons, rods, and crankshaft show significant wear but the cylinder heads remain in good condition, offering a cost-effective balance between rebuilding and full replacement. Selecting a short block minimizes labor time because it includes pre-assembled rotating assembly parts, which enhances installation efficiency compared to assembling each component individually. Opt for a short block when comprehensive internal engine damage exists, yet you want to retain your existing cylinder heads, making it a strategic choice for optimizing repair durability and performance.

Expert Tips for Choosing Between Rotating Assembly and Short Block

When deciding between a rotating assembly and a short block for engine repair, consider the extent of internal damage and budget constraints. Rotating assemblies include key components like the crankshaft, connecting rods, and pistons, offering comprehensive rebuilds ideal for worn or damaged internals. Short blocks provide a more cost-effective option by supplying the engine block, crankshaft, and pistons without the cylinder head, suitable for repairs when the head and valve train are reusable.

Rotating Assembly vs Short Block Infographic

cardiffo.com

cardiffo.com