Wet sump lubrication stores oil in a pan beneath the engine, offering simplicity and lower cost but posing risks of oil starvation during high-performance conditions. Dry sump systems use external reservoirs and pumps to circulate oil, ensuring consistent lubrication and improved engine cooling, ideal for racing and heavy-duty applications. Choosing between them depends on the engine design, performance requirements, and maintenance considerations.

Table of Comparison

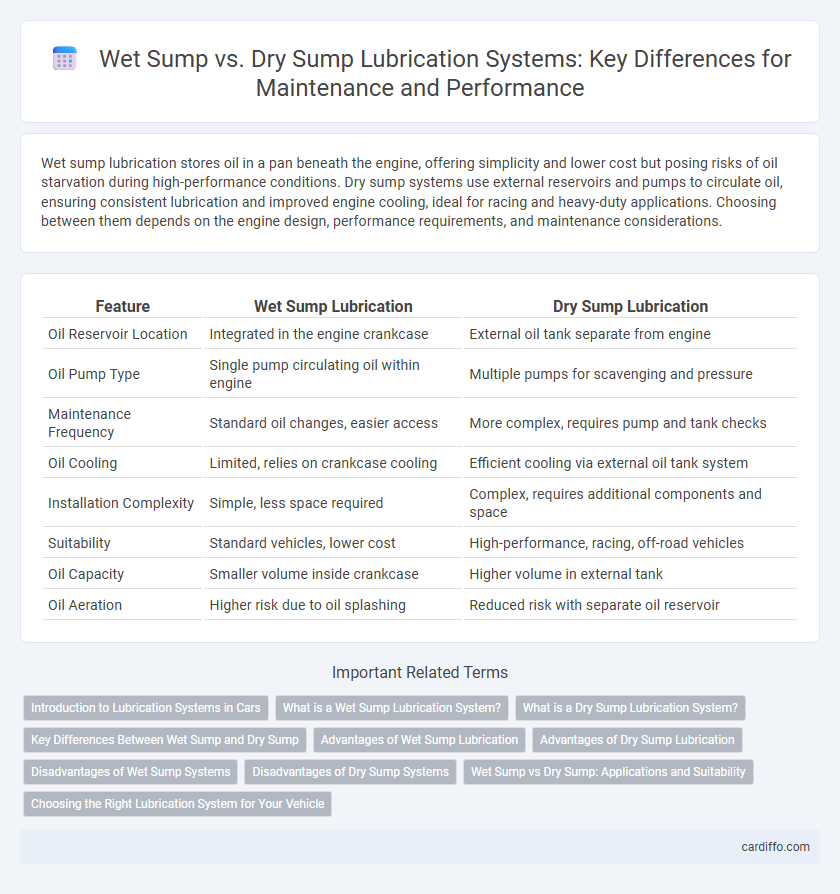

| Feature | Wet Sump Lubrication | Dry Sump Lubrication |

|---|---|---|

| Oil Reservoir Location | Integrated in the engine crankcase | External oil tank separate from engine |

| Oil Pump Type | Single pump circulating oil within engine | Multiple pumps for scavenging and pressure |

| Maintenance Frequency | Standard oil changes, easier access | More complex, requires pump and tank checks |

| Oil Cooling | Limited, relies on crankcase cooling | Efficient cooling via external oil tank system |

| Installation Complexity | Simple, less space required | Complex, requires additional components and space |

| Suitability | Standard vehicles, lower cost | High-performance, racing, off-road vehicles |

| Oil Capacity | Smaller volume inside crankcase | Higher volume in external tank |

| Oil Aeration | Higher risk due to oil splashing | Reduced risk with separate oil reservoir |

Introduction to Lubrication Systems in Cars

Wet sump lubrication systems store engine oil in a pan beneath the crankshaft, providing continuous oil flow through gravity and a pump, ideal for standard passenger vehicles due to simplicity and cost-effectiveness. Dry sump systems use external reservoirs and multiple pumps to circulate oil, preventing oil starvation during high-performance driving or extreme angles, common in racing and off-road vehicles. Understanding the differences in oil circulation, reservoir location, and system complexity is crucial for selecting appropriate lubrication based on vehicle application and maintenance demands.

What is a Wet Sump Lubrication System?

A wet sump lubrication system stores engine oil in a pan located directly beneath the crankshaft, allowing oil to be circulated by a pump to lubricate engine components. This design simplifies maintenance by integrating the oil reservoir within the engine block, reducing complexity and weight. Commonly used in most passenger vehicles, wet sump systems provide efficient lubrication under typical driving conditions but may be less effective during extreme performance or off-road scenarios.

What is a Dry Sump Lubrication System?

A dry sump lubrication system uses external reservoirs to store and circulate oil, preventing oil starvation during high-performance or off-road driving conditions. This system improves engine reliability by maintaining consistent oil pressure and reducing oil aeration. It is commonly employed in motorsports and high-performance vehicles where effective oil management is critical.

Key Differences Between Wet Sump and Dry Sump

Wet sump lubrication stores oil in a pan beneath the engine, simplifying design and reducing cost but limiting oil capacity and cooling efficiency. Dry sump lubrication uses an external reservoir and multiple scavenging pumps, enhancing oil control, preventing oil starvation during high-performance operation, and improving engine cooling. This system is preferred in racing and high-performance vehicles due to its superior oil management and consistent lubrication under extreme conditions.

Advantages of Wet Sump Lubrication

Wet sump lubrication offers simpler design and lower manufacturing costs compared to dry sump systems, making it ideal for everyday vehicles. Its integrated oil reservoir within the engine crankcase reduces complexity and maintenance requirements, enhancing reliability. Wet sump systems ensure efficient lubrication for typical driving conditions while minimizing space and weight.

Advantages of Dry Sump Lubrication

Dry sump lubrication offers superior oil control by preventing oil starvation during high-performance or off-road driving. It enhances engine cooling and reliability through consistent oil circulation and reduces crankcase pressure, minimizing leaks and seal wear. This system also allows for a lower engine placement, improving the vehicle's center of gravity and handling.

Disadvantages of Wet Sump Systems

Wet sump lubrication systems often face disadvantages including oil starvation during high-performance cornering or steep inclines due to oil sloshing away from the pickup. The pooling of oil in the sump increases parasitic drag, reducing engine efficiency and power output. Additionally, wet sump systems are prone to overheating as the oil capacity and cooling surface area are limited compared to dry sump configurations.

Disadvantages of Dry Sump Systems

Dry sump lubrication systems entail higher complexity and cost due to additional components such as external oil reservoirs, scavenging pumps, and extensive plumbing. Maintenance challenges increase with the need for frequent inspection of hoses and seals to prevent leaks and contamination. Furthermore, dry sump setups require more space and weight, making them less suitable for compact or lightweight applications.

Wet Sump vs Dry Sump: Applications and Suitability

Wet sump lubrication systems are commonly used in passenger cars and light trucks due to their simplicity, lower cost, and ease of maintenance, making them suitable for everyday driving conditions and moderate engine loads. Dry sump lubrication is favored in high-performance, racing, and heavy-duty applications where consistent oil pressure and superior engine cooling are critical, as it prevents oil starvation during high G-forces and allows for lower engine placement. The choice between wet sump and dry sump systems depends on factors such as engine design, operational demands, and desired performance characteristics.

Choosing the Right Lubrication System for Your Vehicle

Selecting the appropriate lubrication system for your vehicle depends on factors such as engine design, operating conditions, and performance requirements. Wet sump systems offer simplicity and lower cost, ideal for standard driving and everyday maintenance, while dry sump systems provide superior oil control, improved cooling, and enhanced performance for high-performance or racing engines. Consider vehicle usage and maintenance capabilities to ensure optimal engine longevity and efficiency.

Wet Sump vs Dry Sump Lubrication Infographic

cardiffo.com

cardiffo.com