Direct injection cleaning targets fuel injectors located inside the combustion chamber, effectively removing carbon deposits that impair engine performance. Port injection cleaning focuses on injectors positioned outside the combustion chamber, enhancing fuel atomization and preventing intake valve buildup. Choosing the appropriate cleaning method depends on the vehicle's fuel system type to ensure optimal engine efficiency and longevity.

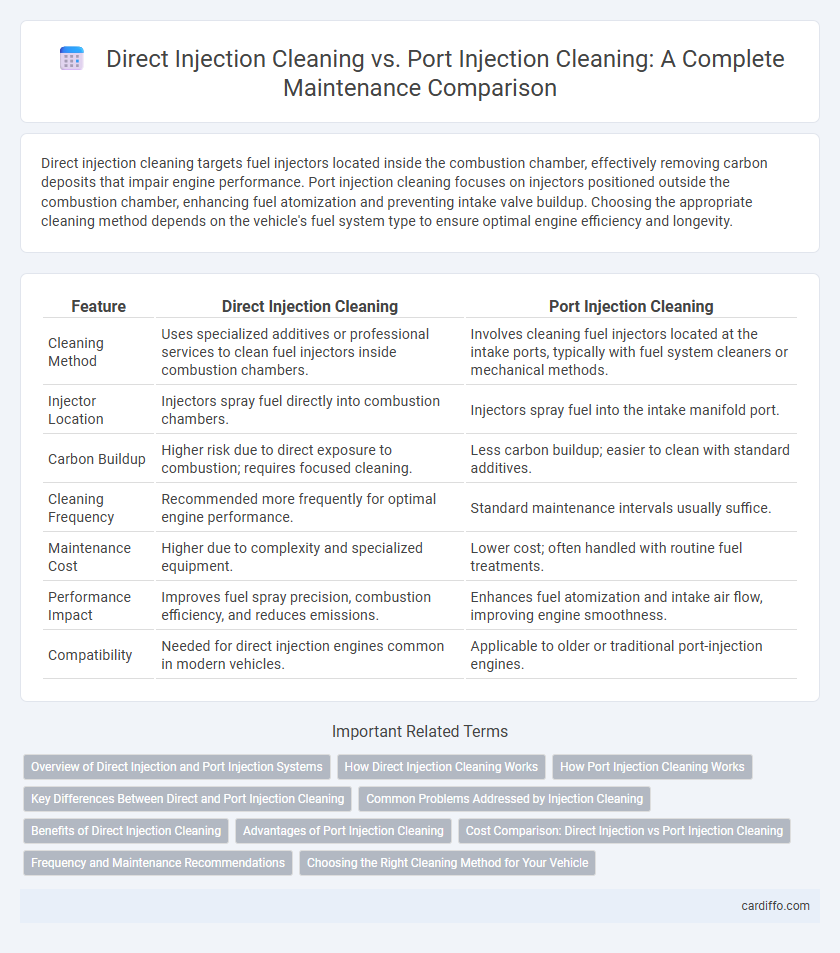

Table of Comparison

| Feature | Direct Injection Cleaning | Port Injection Cleaning |

|---|---|---|

| Cleaning Method | Uses specialized additives or professional services to clean fuel injectors inside combustion chambers. | Involves cleaning fuel injectors located at the intake ports, typically with fuel system cleaners or mechanical methods. |

| Injector Location | Injectors spray fuel directly into combustion chambers. | Injectors spray fuel into the intake manifold port. |

| Carbon Buildup | Higher risk due to direct exposure to combustion; requires focused cleaning. | Less carbon buildup; easier to clean with standard additives. |

| Cleaning Frequency | Recommended more frequently for optimal engine performance. | Standard maintenance intervals usually suffice. |

| Maintenance Cost | Higher due to complexity and specialized equipment. | Lower cost; often handled with routine fuel treatments. |

| Performance Impact | Improves fuel spray precision, combustion efficiency, and reduces emissions. | Enhances fuel atomization and intake air flow, improving engine smoothness. |

| Compatibility | Needed for direct injection engines common in modern vehicles. | Applicable to older or traditional port-injection engines. |

Overview of Direct Injection and Port Injection Systems

Direct injection systems spray fuel directly into the combustion chamber, allowing for precise fuel delivery and improved engine efficiency. Port injection systems inject fuel into the intake manifold, mixing it with air before entering the combustion chamber, which helps maintain cleaner intake valves. Both systems require specialized cleaning techniques to optimize performance and prevent buildup, with direct injection systems often accumulating more deposits due to lack of fuel washing over intake valves.

How Direct Injection Cleaning Works

Direct Injection Cleaning works by removing carbon deposits directly from the fuel injectors and combustion chamber using specialized cleaning solvents or ultrasonic cleaning methods. This process targets the high-pressure fuel spray nozzles to restore proper atomization and combustion efficiency. It improves engine performance, fuel economy, and reduces emissions by ensuring precise fuel delivery.

How Port Injection Cleaning Works

Port injection cleaning involves injecting a specialized cleaning solution directly into the intake ports of an engine to dissolve and remove carbon deposits from the intake valves and ports. This method enhances fuel atomization and combustion efficiency by ensuring cleaner air and fuel mixture delivery. The process typically requires a service technician to access the intake manifold and apply the cleaning agent while the engine is running under specific conditions to maximize deposit removal.

Key Differences Between Direct and Port Injection Cleaning

Direct Injection Cleaning targets fuel injectors located inside the combustion chamber, effectively removing carbon buildup that impairs spray patterns and engine performance. Port Injection Cleaning focuses on the intake valves and throttle body, addressing deposits that can cause rough idling and reduced fuel atomization. The primary difference lies in the cleaning locations and methods, with direct injection cleaning often requiring specialized equipment due to its in-cylinder application.

Common Problems Addressed by Injection Cleaning

Direct injection cleaning and port injection cleaning both target carbon buildup, which is a prevalent issue leading to poor engine performance, rough idling, and increased emissions. Direct injected engines often face severe carbon deposits on intake valves due to fuel not passing over them, while port injection cleaning effectively removes deposits from intake ports and valves. Both methods restore optimal fuel atomization and combustion efficiency, reducing misfires and improving overall engine longevity.

Benefits of Direct Injection Cleaning

Direct injection cleaning enhances engine efficiency by effectively removing carbon deposits directly from the combustion chamber and fuel injectors, improving fuel atomization and combustion quality. It reduces engine knocking and emissions while restoring lost power and fuel economy in GDI engines. This targeted cleaning method extends engine life and optimizes performance compared to traditional port injection cleaning.

Advantages of Port Injection Cleaning

Port Injection Cleaning offers enhanced fuel system efficiency by targeting deposits directly on intake valves, improving airflow and combustion quality. This method reduces the risk of valve deposits that are common with direct injection systems, leading to smoother engine performance and lower emissions. Regular port injection cleaning extends engine life by maintaining optimal fuel atomization and preventing costly repairs associated with clogged injectors.

Cost Comparison: Direct Injection vs Port Injection Cleaning

Direct injection cleaning typically incurs higher costs due to the need for specialized equipment and more labor-intensive procedures compared to port injection cleaning. Port injection cleaning offers a more affordable maintenance option, leveraging simpler access points and less intensive cleaning processes. Vehicle owners should consider the long-term benefits and frequency of each cleaning type to optimize maintenance expenses effectively.

Frequency and Maintenance Recommendations

Direct injection cleaning is recommended every 30,000 to 50,000 miles due to carbon buildup directly on the intake valves, requiring specialized cleaning methods like walnut blasting or chemical solvents. Port injection cleaning, which addresses deposits on the intake ports, typically needs maintenance every 60,000 miles or during routine intake system service to ensure optimal fuel atomization and engine performance. Regular adherence to these intervals helps prevent engine knocking, maintain fuel efficiency, and reduce harmful emissions.

Choosing the Right Cleaning Method for Your Vehicle

Direct injection cleaning targets carbon buildup directly on intake valves and fuel injectors, making it essential for modern vehicles with GDI engines prone to fouling. Port injection cleaning, meanwhile, addresses deposits in the intake ports and throttle body, typically suitable for older or port fuel injected engines. Selecting the appropriate method depends on your vehicle's fuel injection system, manufacturer recommendations, and signs of reduced engine performance or efficiency.

Direct Injection Cleaning vs Port Injection Cleaning Infographic

cardiffo.com

cardiffo.com