Rotary engine maintenance requires specialized attention to apex seals and rotor housing to prevent leaks and ensure optimal combustion, while piston engine maintenance focuses on piston rings, valves, and cylinder walls to maintain compression and prevent wear. Rotary engines typically demand more frequent oil changes and careful monitoring of apex seal condition due to their unique rotor design. In contrast, piston engines benefit from established maintenance routines like regular oil changes, spark plug replacement, and valve adjustments to ensure longevity and performance.

Table of Comparison

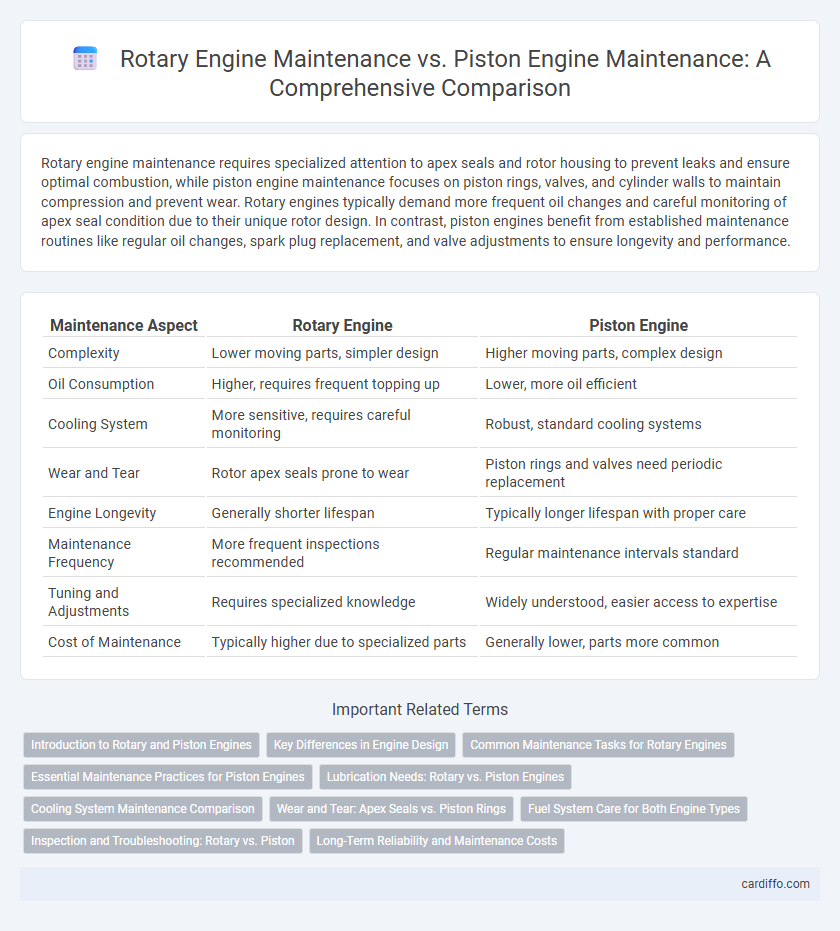

| Maintenance Aspect | Rotary Engine | Piston Engine |

|---|---|---|

| Complexity | Lower moving parts, simpler design | Higher moving parts, complex design |

| Oil Consumption | Higher, requires frequent topping up | Lower, more oil efficient |

| Cooling System | More sensitive, requires careful monitoring | Robust, standard cooling systems |

| Wear and Tear | Rotor apex seals prone to wear | Piston rings and valves need periodic replacement |

| Engine Longevity | Generally shorter lifespan | Typically longer lifespan with proper care |

| Maintenance Frequency | More frequent inspections recommended | Regular maintenance intervals standard |

| Tuning and Adjustments | Requires specialized knowledge | Widely understood, easier access to expertise |

| Cost of Maintenance | Typically higher due to specialized parts | Generally lower, parts more common |

Introduction to Rotary and Piston Engines

Rotary engines, characterized by their Wankel design, utilize a triangular rotor that revolves within an epitrochoid-shaped housing, offering fewer moving parts and a compact size compared to traditional piston engines. Piston engines operate through reciprocating pistons that move up and down within cylinders, relying on valves and a crankshaft to convert combustion into mechanical power. Understanding these fundamental structural differences is essential for targeted maintenance strategies, as rotary engines demand attention to rotor seals and housing wear, while piston engines require regular inspection of pistons, rings, and valve components.

Key Differences in Engine Design

Rotary engines feature a triangular rotor that spins within an epitrochoid housing, simplifying moving parts compared to the multiple pistons and complex valve mechanisms in piston engines. This design reduces the number of components requiring regular maintenance but demands specialized attention to rotor apex seals, which are critical for engine compression. Piston engines typically require frequent oil changes, valve adjustments, and timing belt replacements due to their intricate reciprocating motion and higher number of wear points.

Common Maintenance Tasks for Rotary Engines

Rotary engine maintenance primarily involves regular inspection and replacement of apex seals, which are critical for engine compression and preventing oil leakage. Routine oil changes are essential due to higher oil consumption rates compared to piston engines, alongside frequent spark plug checks to ensure efficient combustion. Unlike piston engines, rotary engines require careful monitoring of rotor housing conditions and cooling system performance to avoid overheating and maintain optimal engine longevity.

Essential Maintenance Practices for Piston Engines

Essential maintenance practices for piston engines include regular oil changes to ensure proper lubrication and prevent wear, timely replacement of spark plugs to maintain efficient combustion, and routine inspection of the cooling system to avoid overheating. Valve adjustments and fuel system cleaning are critical for preserving engine performance and fuel efficiency. Monitoring compression levels and checking for leaks in gaskets and seals further extend engine longevity and reliability.

Lubrication Needs: Rotary vs. Piston Engines

Rotary engines require a unique lubrication system that continuously injects oil directly into the combustion chamber to lubricate the apex seals, preventing rapid wear and ensuring smooth operation. Piston engines rely on an oil sump and pump system to circulate oil through bearings and cylinder walls, with regular oil changes critical to maintaining engine longevity. The distinct lubrication needs of rotary engines often result in higher oil consumption compared to piston engines, necessitating more frequent monitoring and oil top-ups.

Cooling System Maintenance Comparison

Rotary engines require meticulous cooling system maintenance due to their higher operating temperatures and unique rotor design, which demands consistent coolant flow and temperature regulation to prevent overheating. Piston engines typically have more robust and accessible cooling systems, with routine checks on radiator, thermostat, and water pump being straightforward but essential to avoid engine damage. Proper maintenance of cooling components in rotary engines is crucial for performance and longevity, whereas piston engines benefit from easier detection and repair of cooling system issues.

Wear and Tear: Apex Seals vs. Piston Rings

Rotary engine maintenance requires frequent inspection of apex seals, as their wear and tear directly impact engine compression and performance, often deteriorating faster than piston rings due to constant contact with the rotor housing. Piston engine maintenance involves monitoring piston rings for wear, which affects oil control and combustion efficiency, but these rings typically last longer with regular oil changes and less intense sealing pressures. The distinct wear patterns between apex seals and piston rings necessitate tailored maintenance schedules to prevent performance loss and costly repairs.

Fuel System Care for Both Engine Types

Rotary engine fuel systems demand precise attention to prevent apex seal wear and ensure optimal combustion, involving frequent inspection of fuel injectors and carburetors for residue build-up. Piston engines require regular cleaning and maintenance of fuel filters and injectors to avoid clogging and maintain efficient fuel delivery. Both engine types benefit from using high-quality fuel and periodic throttle body cleaning to sustain engine performance and fuel economy.

Inspection and Troubleshooting: Rotary vs. Piston

Rotary engine maintenance requires frequent inspection of apex seals, rotor housings, and side seals to prevent compression loss, while piston engine maintenance focuses on cylinder wear, piston rings, and valve conditions. Troubleshooting rotary engines often involves monitoring for apex seal wear and combustion chamber carbon buildup, whereas piston engines require checking for piston skirt damage, head gasket failure, and valve timing issues. Proper inspection tools like borescopes benefit both, but rotary engines demand more specialized diagnostic techniques due to their unique rotary combustion process.

Long-Term Reliability and Maintenance Costs

Rotary engine maintenance typically involves fewer moving parts, resulting in reduced mechanical wear and potentially lower long-term maintenance costs compared to piston engines, which have complex valve and piston assemblies requiring frequent inspection and replacement. However, rotary engines may demand more specialized attention for apex seal wear and cooling system upkeep to maintain reliability over time. Piston engines benefit from widely available parts and established maintenance procedures, but their higher number of components and increased likelihood of issues such as piston ring and valve wear generally increase long-term maintenance expenses.

Rotary Engine Maintenance vs Piston Engine Maintenance Infographic

cardiffo.com

cardiffo.com