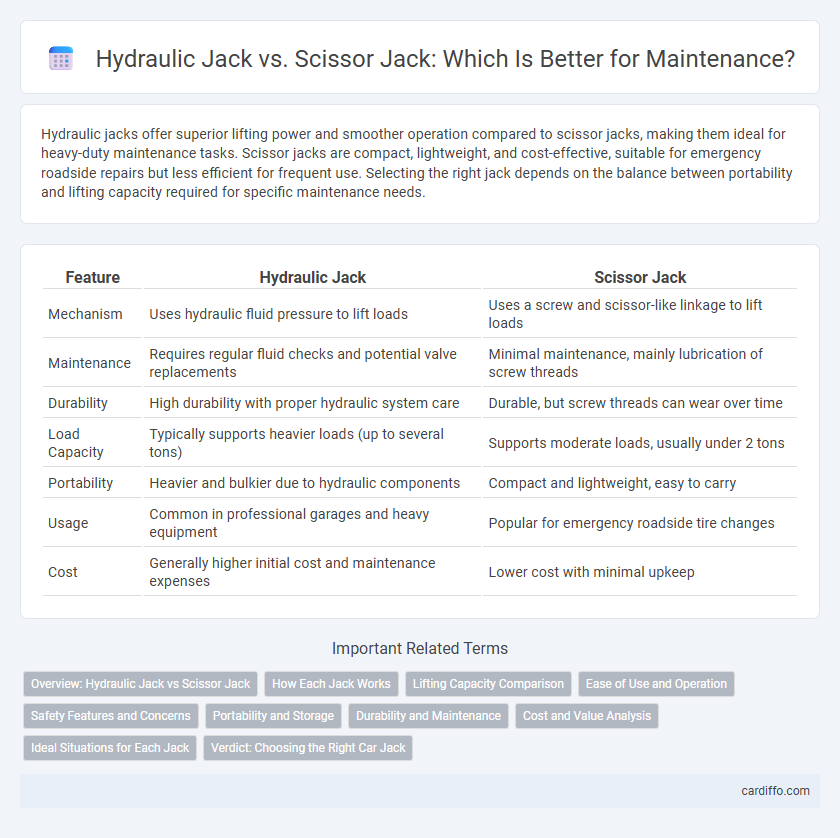

Hydraulic jacks offer superior lifting power and smoother operation compared to scissor jacks, making them ideal for heavy-duty maintenance tasks. Scissor jacks are compact, lightweight, and cost-effective, suitable for emergency roadside repairs but less efficient for frequent use. Selecting the right jack depends on the balance between portability and lifting capacity required for specific maintenance needs.

Table of Comparison

| Feature | Hydraulic Jack | Scissor Jack |

|---|---|---|

| Mechanism | Uses hydraulic fluid pressure to lift loads | Uses a screw and scissor-like linkage to lift loads |

| Maintenance | Requires regular fluid checks and potential valve replacements | Minimal maintenance, mainly lubrication of screw threads |

| Durability | High durability with proper hydraulic system care | Durable, but screw threads can wear over time |

| Load Capacity | Typically supports heavier loads (up to several tons) | Supports moderate loads, usually under 2 tons |

| Portability | Heavier and bulkier due to hydraulic components | Compact and lightweight, easy to carry |

| Usage | Common in professional garages and heavy equipment | Popular for emergency roadside tire changes |

| Cost | Generally higher initial cost and maintenance expenses | Lower cost with minimal upkeep |

Overview: Hydraulic Jack vs Scissor Jack

Hydraulic jacks utilize fluid pressure to lift heavier loads with less effort, making them ideal for frequent or heavy-duty maintenance tasks. Scissor jacks operate with a mechanical screw mechanism and are typically lighter, more compact, and suited for emergency or occasional use. Choosing between a hydraulic jack and a scissor jack depends on factors such as load capacity, ease of use, portability, and maintenance needs.

How Each Jack Works

A hydraulic jack operates by using fluid pressure to lift heavy loads effortlessly, with a pump that forces hydraulic fluid into a cylinder, causing the piston to rise and raise the load. In contrast, a scissor jack relies on a mechanical screw mechanism that expands or contracts the arms in a scissor-like motion to lift the vehicle manually. Hydraulic jacks provide smoother, faster lifting with greater force, while scissor jacks are simpler, lighter, and require more physical effort.

Lifting Capacity Comparison

Hydraulic jacks typically offer a lifting capacity ranging from 2 to 20 tons, making them suitable for heavy-duty vehicle maintenance and industrial applications. In contrast, scissor jacks generally provide a lifting capacity between 1 to 1.5 tons, ideal for smaller passenger cars and emergency roadside use. The significant difference in lifting capacity highlights hydraulic jacks as the preferred choice for professional mechanics requiring higher load support.

Ease of Use and Operation

Hydraulic jacks offer superior ease of use and operation due to their ability to lift heavy loads with minimal physical effort, requiring just a few pumps of the handle. Scissor jacks demand more manual effort and time, as they rely on mechanical leverage through a screw mechanism, making them less user-friendly in emergency situations. For routine vehicle maintenance, hydraulic jacks reduce operator fatigue and improve efficiency, particularly when lifting heavier vehicles or making frequent adjustments.

Safety Features and Concerns

Hydraulic jacks provide superior lifting power with built-in pressure relief valves that prevent overloading and enhance safety during maintenance tasks. Scissor jacks rely on mechanical leverage and typically include locking mechanisms to stabilize the load but pose higher risks if improperly positioned or overloaded. Proper inspection, secure placement, and adherence to load limits are critical safety measures for both hydraulic and scissor jacks to prevent accidents and equipment failure.

Portability and Storage

Hydraulic jacks offer compact designs with moderate weight, making them portable yet slightly bulkier for storage compared to scissor jacks. Scissor jacks are lightweight, foldable, and easily stored in tight spaces such as car trunks, ideal for on-the-go maintenance. Choosing between the two depends on balancing portability needs and storage constraints during vehicle maintenance.

Durability and Maintenance

Hydraulic jacks feature robust steel construction and sealed hydraulic systems, providing superior durability and requiring minimal maintenance compared to scissor jacks. Scissor jacks, typically made from lighter metals and relying on screw mechanisms, are more prone to wear and corrosion, demanding frequent lubrication and inspection. Regular maintenance of hydraulic fluid levels and seals extends the lifespan of hydraulic jacks, whereas scissor jacks require careful cleaning and tightening of moving parts to ensure safe operation.

Cost and Value Analysis

Hydraulic jacks generally offer higher lifting capacity and faster operation, justifying their higher initial cost compared to scissor jacks, which are more affordable but less durable. The cost-effectiveness of hydraulic jacks increases with frequent use due to improved efficiency and reduced physical effort, making them ideal for professional maintenance environments. Scissor jacks provide sufficient value for occasional use and lighter vehicles, balancing lower purchase price with limited mechanical advantage and slower lift times.

Ideal Situations for Each Jack

Hydraulic jacks are ideal for lifting heavier loads and provide smoother, more controlled lifting, making them suitable for automotive repairs and industrial maintenance where precision and strength are paramount. Scissor jacks are best suited for emergencies or occasional use due to their lightweight, compact design, and ease of manual operation, making them perfect for changing tires on the roadside. Each jack's ideal situation depends on factors such as load capacity, portability, and the nature of the maintenance task.

Verdict: Choosing the Right Car Jack

Hydraulic jacks provide superior lifting power and efficiency, making them ideal for heavier vehicles and frequent use, while scissor jacks are compact, lightweight, and suitable for emergency roadside repairs. Consider vehicle weight, frequency of maintenance, and storage space when selecting between hydraulic and scissor jacks. Prioritizing hydraulic jacks enhances safety and speed in professional settings, whereas scissor jacks offer convenience for occasional, light-duty tasks.

Hydraulic jack vs scissor jack Infographic

cardiffo.com

cardiffo.com