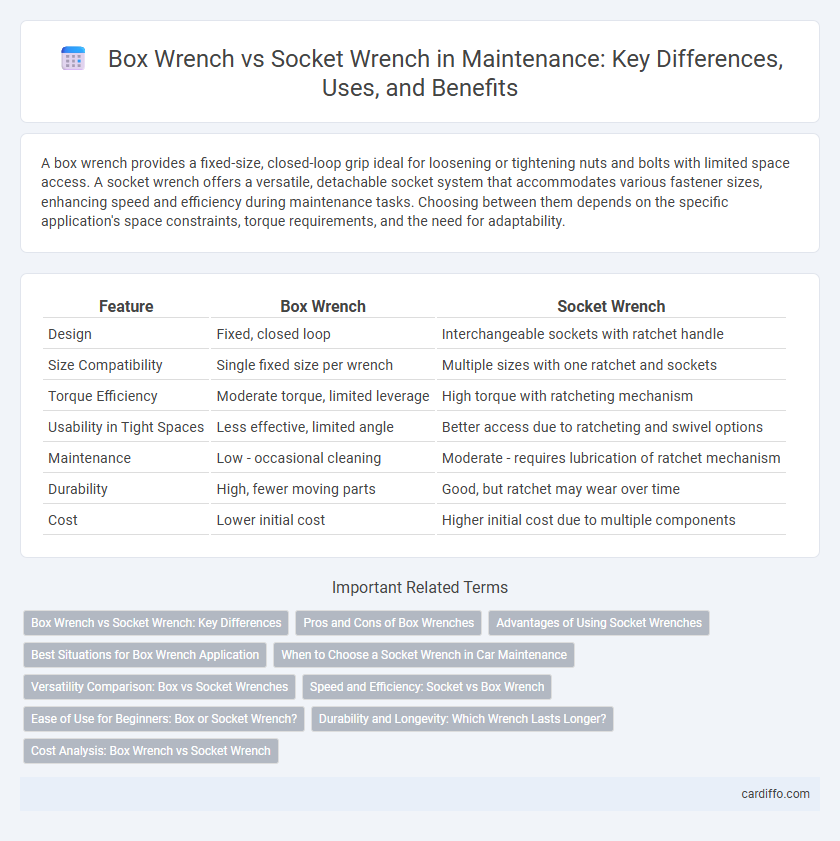

A box wrench provides a fixed-size, closed-loop grip ideal for loosening or tightening nuts and bolts with limited space access. A socket wrench offers a versatile, detachable socket system that accommodates various fastener sizes, enhancing speed and efficiency during maintenance tasks. Choosing between them depends on the specific application's space constraints, torque requirements, and the need for adaptability.

Table of Comparison

| Feature | Box Wrench | Socket Wrench |

|---|---|---|

| Design | Fixed, closed loop | Interchangeable sockets with ratchet handle |

| Size Compatibility | Single fixed size per wrench | Multiple sizes with one ratchet and sockets |

| Torque Efficiency | Moderate torque, limited leverage | High torque with ratcheting mechanism |

| Usability in Tight Spaces | Less effective, limited angle | Better access due to ratcheting and swivel options |

| Maintenance | Low - occasional cleaning | Moderate - requires lubrication of ratchet mechanism |

| Durability | High, fewer moving parts | Good, but ratchet may wear over time |

| Cost | Lower initial cost | Higher initial cost due to multiple components |

Box Wrench vs Socket Wrench: Key Differences

Box wrenches feature a fixed closed-loop design that grips fasteners on all sides, providing strong torque without slipping, while socket wrenches use interchangeable sockets attached to a ratcheting handle for versatile access in tight spaces. Box wrenches are ideal for flat, narrow spots and offer durability with no moving parts, whereas socket wrenches excel in speed and convenience for repetitive tasks due to their ratcheting mechanism. Choosing between them depends on the maintenance task's spatial constraints and the required torque application.

Pros and Cons of Box Wrenches

Box wrenches offer excellent grip and torque due to their enclosed design, reducing the risk of slipping on fasteners and minimizing damage to bolt heads. Their solid construction makes them ideal for tight spaces where a socket wrench might not fit, but they lack the versatility of interchangeable sockets, limiting their adaptability to various fastener sizes. However, box wrenches can be bulkier and less convenient for rapid use compared to socket wrenches with ratcheting mechanisms.

Advantages of Using Socket Wrenches

Socket wrenches provide superior torque and ease of use compared to box wrenches, allowing for faster tightening and loosening of bolts in confined spaces. Their ratcheting mechanism enables continuous rotation without removing the tool from the fastener, improving efficiency during maintenance tasks. Socket wrenches also accommodate interchangeable sockets, offering versatility for different bolt sizes and reducing the need for multiple tools.

Best Situations for Box Wrench Application

Box wrenches excel in applications requiring high torque and a strong grip on fasteners in tight spaces where a socket wrench may not fit. Their fixed, closed-loop design minimizes the risk of rounding nuts or bolts, making them ideal for automotive repairs and heavy machinery maintenance. Box wrenches are most effective in confined areas with limited clearance above the fastener.

When to Choose a Socket Wrench in Car Maintenance

Choosing a socket wrench in car maintenance is essential when dealing with fasteners in tight or recessed spaces where a box wrench cannot reach effectively. The socket wrench's ratcheting mechanism allows for continuous turning without removing the tool, speeding up loosening or tightening bolts on engine components, wheel hubs, and suspension parts. Socket wrenches come in various drive sizes, making them versatile for different bolt sizes commonly found in automotive repairs.

Versatility Comparison: Box vs Socket Wrenches

Box wrenches offer fixed sizes and provide excellent grip on fasteners without slipping, making them highly reliable for specific bolt sizes. Socket wrenches come with interchangeable sockets, significantly increasing versatility by accommodating a wide range of fastener sizes and types with one handle. For maintenance tasks requiring adaptability and efficiency across various fasteners, socket wrenches typically outperform box wrenches in versatility.

Speed and Efficiency: Socket vs Box Wrench

Socket wrenches deliver superior speed and efficiency over box wrenches by enabling quick ratcheting motions without the need to reposition the tool after each turn. The ratchet mechanism in socket wrenches reduces the time spent loosening or tightening fasteners, making them ideal for repetitive maintenance tasks. Box wrenches require manual repositioning, which slows down the process, especially in tight spaces or when working with numerous bolts.

Ease of Use for Beginners: Box or Socket Wrench?

Box wrenches offer simplicity and direct grip on fasteners, making them easier for beginners to handle without complex setups. Socket wrenches provide more versatility with ratcheting mechanisms, reducing hand fatigue and speeding up repetitive tasks once users understand the tool's operation. For ease of use, novices often prefer box wrenches due to straightforward design and minimal adjustments required during maintenance work.

Durability and Longevity: Which Wrench Lasts Longer?

Box wrenches are typically made from high-strength steel alloys, providing excellent durability and resistance to wear, which contributes to their long lifespan in maintenance tasks. Socket wrenches, often constructed with chrome vanadium steel, combine strength with corrosion resistance, enhancing their longevity especially under heavy use. Both tools offer long-lasting performance, but socket wrenches usually last longer due to their versatile design and more robust material treatment.

Cost Analysis: Box Wrench vs Socket Wrench

Box wrenches generally cost less upfront due to their simpler design and fewer components, making them ideal for basic maintenance tasks with limited budgets. Socket wrenches, while initially more expensive, offer greater versatility and efficiency, potentially reducing overall labor costs in complex or repetitive maintenance work. Long-term cost analysis favors socket wrenches for professional use due to their durability and adaptability across various fastener sizes.

Box wrench vs Socket wrench Infographic

cardiffo.com

cardiffo.com