Fuel Stratified Injection delivers fuel directly into the combustion chamber in layers, enhancing fuel efficiency and reducing emissions by creating richer mixtures near the spark plug and leaner mixtures elsewhere. Homogeneous Charge Injection mixes fuel and air uniformly before combustion, promoting smoother and more complete burning but often leading to higher fuel consumption. Choosing between these injection methods depends on the desired balance between performance, fuel economy, and emission standards.

Table of Comparison

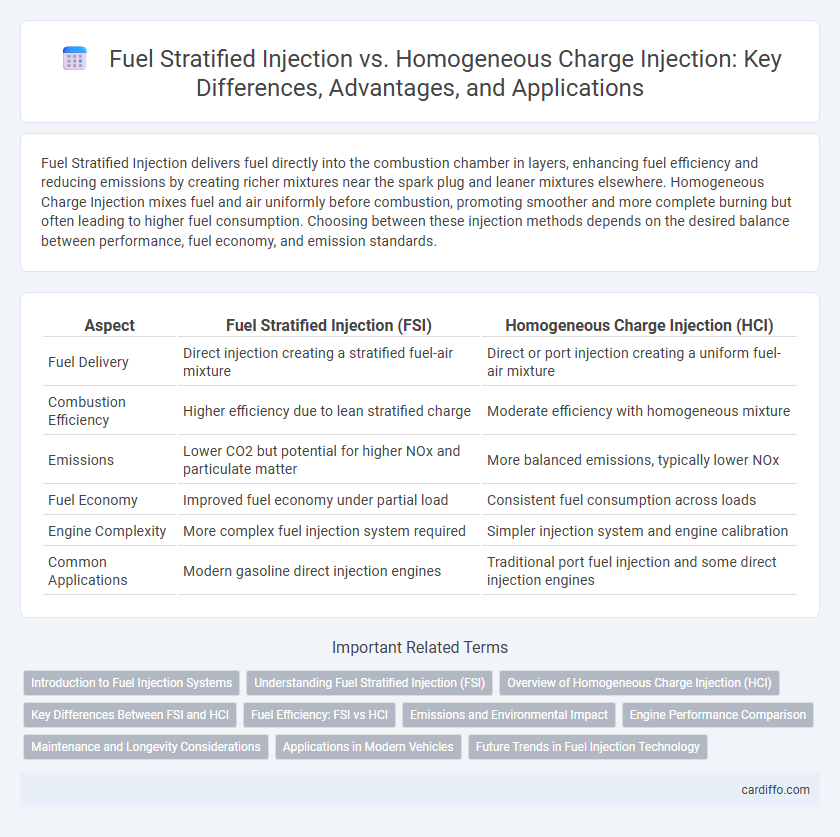

| Aspect | Fuel Stratified Injection (FSI) | Homogeneous Charge Injection (HCI) |

|---|---|---|

| Fuel Delivery | Direct injection creating a stratified fuel-air mixture | Direct or port injection creating a uniform fuel-air mixture |

| Combustion Efficiency | Higher efficiency due to lean stratified charge | Moderate efficiency with homogeneous mixture |

| Emissions | Lower CO2 but potential for higher NOx and particulate matter | More balanced emissions, typically lower NOx |

| Fuel Economy | Improved fuel economy under partial load | Consistent fuel consumption across loads |

| Engine Complexity | More complex fuel injection system required | Simpler injection system and engine calibration |

| Common Applications | Modern gasoline direct injection engines | Traditional port fuel injection and some direct injection engines |

Introduction to Fuel Injection Systems

Fuel Stratified Injection (FSI) delivers fuel directly into the combustion chamber in a stratified manner, creating a fuel-rich zone near the spark plug for efficient ignition and improved fuel economy. Homogeneous Charge Injection (HCI) mixes air and fuel uniformly before combustion, resulting in a consistent air-fuel mixture that enhances smooth engine operation and reduces emissions. Both systems utilize advanced fuel injection technology to optimize combustion efficiency and meet stringent environmental regulations.

Understanding Fuel Stratified Injection (FSI)

Fuel Stratified Injection (FSI) enhances combustion efficiency by injecting fuel directly into the combustion chamber in precise layers, creating a rich fuel mixture near the spark plug and a leaner mixture elsewhere. This targeted injection reduces fuel consumption and lowers emissions compared to Homogeneous Charge Injection, which disperses fuel uniformly throughout the cylinder. FSI's ability to control fuel distribution optimizes ignition timing and combustion stability, leading to improved engine performance and reduced pollutant formation.

Overview of Homogeneous Charge Injection (HCI)

Homogeneous Charge Injection (HCI) delivers fuel uniformly mixed with air before combustion, promoting consistent flame propagation and reduced local emissions. This technique improves fuel atomization and vaporization, enhancing combustion efficiency compared to stratified injection methods. HCI systems typically result in lower particulate matter and nitrogen oxide formation due to the more evenly distributed fuel-air mixture.

Key Differences Between FSI and HCI

Fuel Stratified Injection (FSI) delivers fuel directly into the combustion chamber in multiple stratified layers, optimizing air-fuel mixture for improved fuel efficiency and reduced emissions. Homogeneous Charge Injection (HCI) mixes fuel and air uniformly before combustion, resulting in a consistent air-fuel ratio that enhances combustion stability and power output. Key differences between FSI and HCI include fuel delivery timing, mixture uniformity, and their impact on emission levels and engine performance.

Fuel Efficiency: FSI vs HCI

Fuel Stratified Injection (FSI) enhances fuel efficiency by delivering precise amounts of fuel directly into the combustion chamber, resulting in better air-fuel mixture control and reduced fuel consumption compared to Homogeneous Charge Injection (HCI). FSI enables leaner combustion under light load conditions by creating stratified charge layers, which lowers emissions and improves thermal efficiency. In contrast, HCI injects fuel uniformly, often leading to higher fuel consumption due to less optimized combustion and increased throttling losses.

Emissions and Environmental Impact

Fuel Stratified Injection (FSI) significantly reduces emissions by optimizing fuel-air mixture in combustion chambers, resulting in lower nitrogen oxides (NOx) and particulate matter compared to Homogeneous Charge Injection (HCI). FSI enhances fuel efficiency and minimizes unburned hydrocarbons, contributing to reduced carbon dioxide (CO2) emissions and better environmental performance. HCI, while simpler, often leads to higher fuel consumption and increased pollutants, making FSI more favorable for stringent emission standards and sustainable automotive technology.

Engine Performance Comparison

Fuel Stratified Injection (FSI) improves engine performance by delivering fuel directly into the combustion chamber in a precisely controlled manner, enhancing fuel efficiency and reducing emissions compared to Homogeneous Charge Injection (HCI). FSI enables a richer fuel mixture near the spark plug while maintaining a leaner overall mixture, resulting in better combustion stability and higher power output at low to mid engine loads. HCI, on the other hand, provides a more uniform air-fuel mixture, which can deliver smoother operation at high loads but typically sacrifices some efficiency and increases emissions.

Maintenance and Longevity Considerations

Fuel Stratified Injection (FSI) systems generally require more frequent maintenance due to the complexity of multiple injection events and precise fuel control, which can lead to higher wear on injectors and sensors. Homogeneous Charge Injection (HCI) simplifies fuel delivery with a uniform air-fuel mixture, resulting in reduced injector fouling and longer component lifespan. Engine longevity under FSI may be affected by carbon buildup on intake valves, whereas HCI systems tend to experience fewer deposits, promoting better long-term reliability.

Applications in Modern Vehicles

Fuel Stratified Injection optimizes combustion in modern direct-injection engines by creating a rich fuel mixture near the spark plug while maintaining a leaner overall air-fuel ratio, enhancing fuel efficiency and reducing emissions. Homogeneous Charge Injection disperses fuel evenly throughout the combustion chamber, ensuring consistent power output and smooth operation in conventional gasoline engines. Stratified injection is increasingly applied in turbocharged gasoline direct injection (GDI) engines for improved fuel economy under low-load conditions, while homogeneous injection remains preferred for steady-state power and lower complexity in traditional port-fuel injection systems.

Future Trends in Fuel Injection Technology

Fuel stratified injection (FSI) offers precise control of fuel delivery by creating layers of varied air-fuel mixtures, enhancing combustion efficiency and reducing emissions. Homogeneous charge injection (HCI) delivers a uniform air-fuel mix, promoting consistent combustion but with less flexibility in emission control. Future trends in fuel injection technology emphasize advanced electronic control systems, real-time combustion monitoring, and integration with hybrid powertrains to optimize fuel efficiency and meet stringent emission standards.

Fuel Stratified Injection vs Homogeneous Charge Injection Infographic

cardiffo.com

cardiffo.com