Oxygenated fuel contains additives such as ethanol or MTBE that introduce oxygen into the combustion process, enhancing fuel efficiency and reducing harmful emissions like carbon monoxide and unburned hydrocarbons. Non-oxygenated fuel lacks these additives, often resulting in lower combustion efficiency and higher pollutant levels. Choosing oxygenated fuel supports cleaner engine performance and complies with stricter environmental regulations.

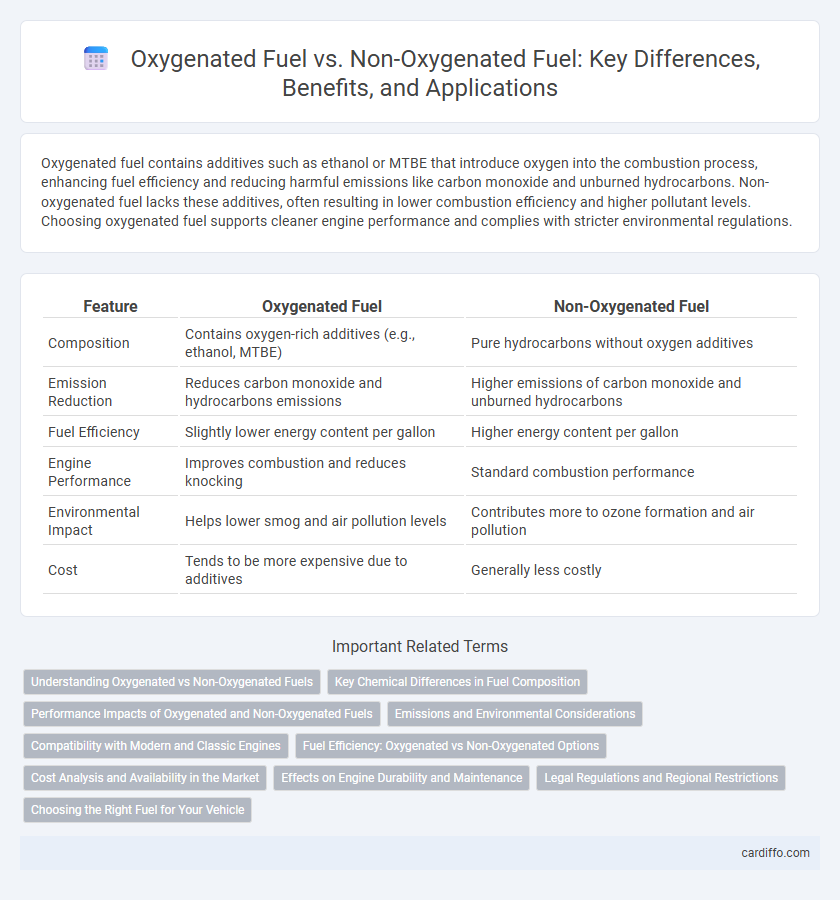

Table of Comparison

| Feature | Oxygenated Fuel | Non-Oxygenated Fuel |

|---|---|---|

| Composition | Contains oxygen-rich additives (e.g., ethanol, MTBE) | Pure hydrocarbons without oxygen additives |

| Emission Reduction | Reduces carbon monoxide and hydrocarbons emissions | Higher emissions of carbon monoxide and unburned hydrocarbons |

| Fuel Efficiency | Slightly lower energy content per gallon | Higher energy content per gallon |

| Engine Performance | Improves combustion and reduces knocking | Standard combustion performance |

| Environmental Impact | Helps lower smog and air pollution levels | Contributes more to ozone formation and air pollution |

| Cost | Tends to be more expensive due to additives | Generally less costly |

Understanding Oxygenated vs Non-Oxygenated Fuels

Oxygenated fuels contain chemically bonded oxygen compounds such as ethanol or MTBE, which promote more complete combustion and reduce emissions of carbon monoxide and unburned hydrocarbons. Non-oxygenated fuels lack these additives, resulting in higher pollutant output but often providing higher energy density. Understanding the chemical composition and environmental impact of oxygenated versus non-oxygenated fuels is crucial for optimizing engine performance and meeting regulatory standards.

Key Chemical Differences in Fuel Composition

Oxygenated fuels contain oxygen-rich compounds such as ethanol or MTBE (methyl tert-butyl ether), which enhance combustion efficiency and reduce carbon monoxide emissions compared to non-oxygenated fuels. Non-oxygenated fuels primarily consist of hydrocarbons like paraffins, naphthenes, and aromatics without added oxygen, resulting in higher particulate and pollutant formation during combustion. The presence of oxygenates alters the fuel's chemical structure, improving volatility and combustion characteristics while impacting energy content and emission profiles.

Performance Impacts of Oxygenated and Non-Oxygenated Fuels

Oxygenated fuel enhances combustion efficiency by promoting more complete fuel burning, resulting in improved engine performance and reduced emissions compared to non-oxygenated fuel. Engines running on oxygenated fuel exhibit increased power output and smoother operation due to higher oxygen content facilitating better fuel-air mixing. Non-oxygenated fuels may produce higher levels of carbon monoxide and unburned hydrocarbons, negatively affecting both performance and environmental impact.

Emissions and Environmental Considerations

Oxygenated fuels contain additives such as ethanol or MTBE that increase the oxygen content, leading to more complete combustion and reduced emissions of carbon monoxide and particulate matter. Non-oxygenated fuels lack these additives, often resulting in higher levels of pollutants like carbon monoxide and unburned hydrocarbons, which contribute to smog and air quality degradation. Environmental considerations favor oxygenated fuels for their ability to lower harmful emissions, supporting improved public health and compliance with air quality standards.

Compatibility with Modern and Classic Engines

Oxygenated fuel contains additives such as ethanol or MTBE that enhance combustion efficiency and reduce emissions, making it highly compatible with modern engines designed to accommodate these substances. Classic engines, however, may experience corrosion or fuel system damage when using oxygenated fuel due to older materials not resistant to ethanol's solvent properties. Non-oxygenated fuel remains preferred for vintage vehicles as it preserves engine integrity and avoids potential issues related to fuel system degradation.

Fuel Efficiency: Oxygenated vs Non-Oxygenated Options

Oxygenated fuel enhances combustion efficiency by increasing oxygen content, leading to more complete fuel burn and reduced carbon monoxide emissions. Non-oxygenated fuel typically offers slightly higher energy content per gallon but may result in less efficient combustion and higher pollutant output. Studies show oxygenated fuels improve fuel efficiency in cold-start conditions and urban driving environments by promoting cleaner engine operation.

Cost Analysis and Availability in the Market

Oxygenated fuels generally incur higher production costs due to the incorporation of additives like ethanol or MTBE, which impact the overall price at the pump. Non-oxygenated fuels are often more readily available across diverse markets, benefiting from established refining and distribution infrastructures. Cost analysis reveals that while oxygenated fuels can command a premium, their environmental benefits and regulatory incentives sometimes offset the higher expenses.

Effects on Engine Durability and Maintenance

Oxygenated fuel, containing additives like ethanol or MTBE, promotes cleaner combustion by reducing carbon deposits and minimizing engine wear, which can enhance engine durability and lower maintenance frequency. Non-oxygenated fuel lacks these additives, potentially leading to increased carbon buildup and sludge formation that accelerate engine component degradation. Engine longevity benefits from oxygenated fuel due to improved combustion efficiency and reduced fouling, resulting in fewer maintenance interventions and extended service intervals.

Legal Regulations and Regional Restrictions

Oxygenated fuels, mandated by regulations such as the U.S. Clean Air Act Amendments, are required in certain regions to reduce carbon monoxide emissions and improve air quality, with strict limits on ethanol or MTBE content. Non-oxygenated fuels face fewer legal restrictions but may be prohibited or restricted in areas with stringent environmental standards due to their higher emission profiles. Regional policies often vary, with states or countries enforcing unique blending requirements to comply with local air quality goals and legal frameworks.

Choosing the Right Fuel for Your Vehicle

Oxygenated fuel contains compounds like ethanol or methanol that enhance combustion efficiency and reduce harmful emissions, making it ideal for vehicles designed to meet strict environmental standards. Non-oxygenated fuel, typically pure gasoline, offers higher energy content per gallon, providing better fuel economy for older or high-performance engines not optimized for oxygenates. Selecting the right fuel depends on your vehicle's engine compatibility, emission regulations, and desired balance between performance and environmental impact.

Oxygenated Fuel vs Non-Oxygenated Fuel Infographic

cardiffo.com

cardiffo.com