Diesel is a petroleum-based fuel commonly used in engines due to its high energy content and efficiency, while biodiesel is derived from renewable biological sources like vegetable oils and animal fats, offering a cleaner-burning alternative with lower emissions. Biodiesel can be blended with traditional diesel to reduce carbon footprint and improve biodegradability without compromising engine performance. Although diesel provides better energy density, biodiesel's environmental benefits and renewability make it a sustainable choice for reducing dependency on fossil fuels.

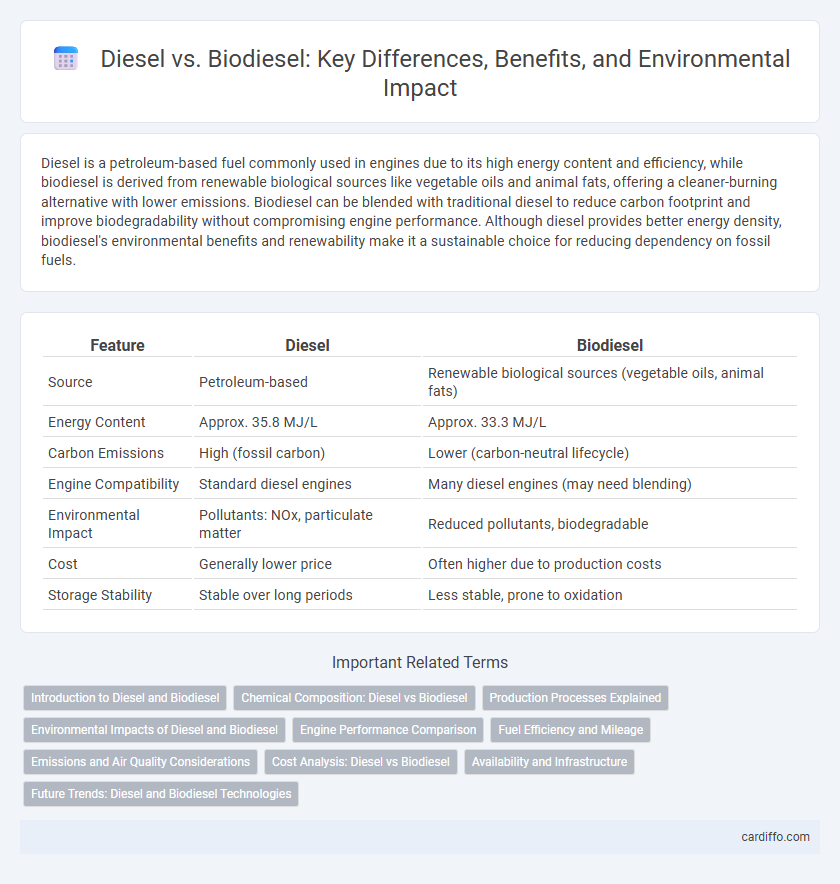

Table of Comparison

| Feature | Diesel | Biodiesel |

|---|---|---|

| Source | Petroleum-based | Renewable biological sources (vegetable oils, animal fats) |

| Energy Content | Approx. 35.8 MJ/L | Approx. 33.3 MJ/L |

| Carbon Emissions | High (fossil carbon) | Lower (carbon-neutral lifecycle) |

| Engine Compatibility | Standard diesel engines | Many diesel engines (may need blending) |

| Environmental Impact | Pollutants: NOx, particulate matter | Reduced pollutants, biodegradable |

| Cost | Generally lower price | Often higher due to production costs |

| Storage Stability | Stable over long periods | Less stable, prone to oxidation |

Introduction to Diesel and Biodiesel

Diesel is a widely used fossil fuel derived from crude oil, known for its high energy density and efficiency in combustion engines, primarily in transportation and heavy machinery. Biodiesel, produced from renewable biological sources like vegetable oils and animal fats, offers a biodegradable and cleaner alternative with lower emissions of particulate matter and greenhouse gases. Both fuels are compatible with diesel engines, but biodiesel promotes sustainability by reducing reliance on finite fossil fuel resources.

Chemical Composition: Diesel vs Biodiesel

Diesel primarily consists of hydrocarbons derived from petroleum, including a complex mixture of paraffins, naphthenes, and aromatics with carbon chains typically ranging from C10 to C22. Biodiesel is composed of fatty acid methyl esters (FAME) produced through the transesterification of vegetable oils or animal fats, containing oxygen atoms within their molecular structure. The presence of oxygen in biodiesel enhances combustion efficiency and reduces emissions compared to conventional diesel, which lacks oxygen in its hydrocarbon framework.

Production Processes Explained

Diesel fuel is primarily produced through the fractional distillation and catalytic cracking of crude oil, yielding hydrocarbons optimized for high energy density and engine performance. Biodiesel, on the other hand, is synthesized through a transesterification process where vegetable oils or animal fats react with methanol or ethanol in the presence of a catalyst, producing fatty acid methyl esters (FAME). These distinct production methods lead to differences in chemical composition, environmental impact, and fuel properties.

Environmental Impacts of Diesel and Biodiesel

Diesel fuel generates higher greenhouse gas emissions and particulate matter compared to biodiesel, contributing significantly to air pollution and climate change. Biodiesel, derived from renewable organic sources like vegetable oil and animal fats, reduces carbon monoxide, unburned hydrocarbons, and particulate emissions while improving biodegradability. The combustion of biodiesel results in lower sulfur dioxide emissions, mitigating acid rain and improving overall air quality in comparison to conventional diesel.

Engine Performance Comparison

Diesel engines typically deliver higher energy content per gallon, resulting in better fuel economy and more consistent power output compared to biodiesel fuels. Biodiesel offers cleaner combustion with lower emissions of particulates and carbon monoxide but may cause slight reductions in engine power and increased fuel consumption due to its lower energy density. Engine performance with biodiesel blends often remains comparable to pure diesel, though long-term effects on fuel system components can vary depending on blend ratios and biodegradability.

Fuel Efficiency and Mileage

Diesel fuel typically offers higher energy density, resulting in better fuel efficiency and longer mileage per gallon compared to biodiesel. Biodiesel, while slightly lower in energy content, provides cleaner combustion and can improve engine performance in certain conditions without compromising mileage significantly. Vehicles running on diesel may achieve approximately 4-5% better mileage compared to those using pure biodiesel blends, though performance varies by blend ratio and engine type.

Emissions and Air Quality Considerations

Diesel fuel combustion releases significant amounts of nitrogen oxides (NOx) and particulate matter (PM), contributing to air pollution and respiratory issues. Biodiesel, derived from renewable sources like vegetable oils, produces lower levels of PM, carbon monoxide (CO), and unburned hydrocarbons, improving air quality compared to petroleum diesel. However, biodiesel can generate slightly higher NOx emissions, requiring optimized engine calibration and emission control technologies to minimize environmental impact.

Cost Analysis: Diesel vs Biodiesel

Diesel fuel generally remains less expensive than biodiesel due to established refining infrastructure and lower production costs tied to crude oil prices. Biodiesel, derived from renewable sources like vegetable oils and animal fats, incurs higher costs related to feedstock acquisition and processing but benefits from government incentives and lower carbon taxes. When evaluating total cost of ownership, biodiesel's premium price is often offset by environmental compliance savings and potential engine longevity improvements, making it a competitive alternative despite a higher upfront fuel cost.

Availability and Infrastructure

Diesel benefits from a well-established global infrastructure with extensive distribution networks, widespread fueling stations, and compatibility with existing engines, making it readily available in most regions. Biodiesel availability is expanding but remains limited due to less developed supply chains, fewer dedicated fueling stations, and challenges in integrating with older diesel engines without modifications. Investment in infrastructure improvements and blending mandates are critical to increasing biodiesel accessibility and supporting its broader adoption.

Future Trends: Diesel and Biodiesel Technologies

Emerging advancements in diesel engine technologies emphasize enhanced fuel efficiency and reduced emissions through improved combustion systems and exhaust after-treatment. Biodiesel development focuses on sustainable feedstocks and bio-refinery innovations, promoting compatibility with existing diesel engines while lowering carbon footprints. Future trends prioritize integration of renewable diesel blends and advanced catalysts to meet stringent environmental standards and support carbon-neutral transportation goals.

Diesel vs Biodiesel Infographic

cardiffo.com

cardiffo.com