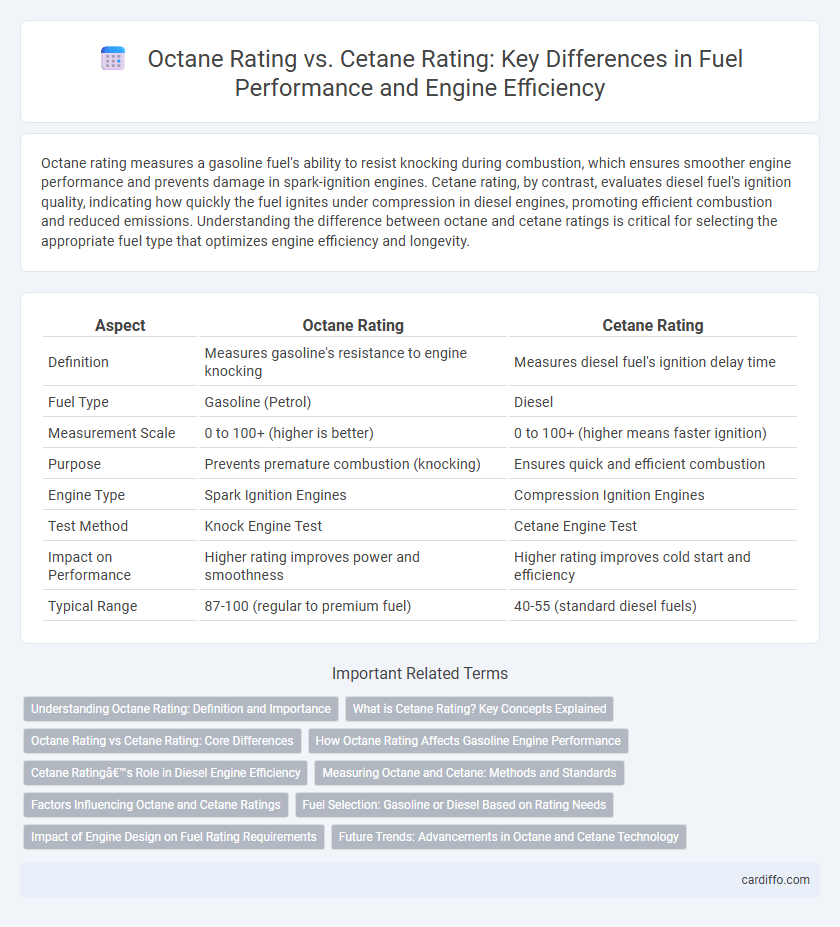

Octane rating measures a gasoline fuel's ability to resist knocking during combustion, which ensures smoother engine performance and prevents damage in spark-ignition engines. Cetane rating, by contrast, evaluates diesel fuel's ignition quality, indicating how quickly the fuel ignites under compression in diesel engines, promoting efficient combustion and reduced emissions. Understanding the difference between octane and cetane ratings is critical for selecting the appropriate fuel type that optimizes engine efficiency and longevity.

Table of Comparison

| Aspect | Octane Rating | Cetane Rating |

|---|---|---|

| Definition | Measures gasoline's resistance to engine knocking | Measures diesel fuel's ignition delay time |

| Fuel Type | Gasoline (Petrol) | Diesel |

| Measurement Scale | 0 to 100+ (higher is better) | 0 to 100+ (higher means faster ignition) |

| Purpose | Prevents premature combustion (knocking) | Ensures quick and efficient combustion |

| Engine Type | Spark Ignition Engines | Compression Ignition Engines |

| Test Method | Knock Engine Test | Cetane Engine Test |

| Impact on Performance | Higher rating improves power and smoothness | Higher rating improves cold start and efficiency |

| Typical Range | 87-100 (regular to premium fuel) | 40-55 (standard diesel fuels) |

Understanding Octane Rating: Definition and Importance

Octane rating measures a fuel's resistance to knocking or premature combustion in gasoline engines, with higher octane numbers indicating greater stability under compression. It is essential for ensuring smooth engine performance and preventing damage caused by engine knocking, especially in high-performance or turbocharged engines. Understanding octane rating helps consumers select the appropriate fuel grade, optimizing engine efficiency and longevity.

What is Cetane Rating? Key Concepts Explained

Cetane rating measures the ignition quality of diesel fuel, indicating how quickly the fuel self-ignites under compression in diesel engines. Higher cetane numbers correspond to shorter ignition delays, improving engine start-up, performance, and reducing emissions. Unlike octane rating, which applies to gasoline and prevents knocking, cetane rating ensures efficient combustion in diesel engines by promoting timely ignition.

Octane Rating vs Cetane Rating: Core Differences

Octane rating measures a fuel's resistance to knocking in gasoline engines by indicating its ability to avoid premature ignition, while cetane rating assesses diesel fuel's combustion quality and ignition delay in compression ignition engines. Higher octane ratings improve engine performance and efficiency in spark-ignition engines, whereas higher cetane numbers enhance combustion speed and reduce emissions in diesel engines. Understanding these core differences helps optimize fuel selection for engine type, ensuring proper combustion and engine longevity.

How Octane Rating Affects Gasoline Engine Performance

Octane rating measures a gasoline fuel's ability to resist knocking or pre-ignition during combustion, directly influencing engine performance and smoothness. Higher octane fuels allow for higher compression ratios and more advanced ignition timing, leading to increased power output and efficiency in high-performance engines. Using fuel with an octane rating below the engine's requirement can cause knocking, reduce fuel economy, and potentially damage internal components.

Cetane Rating’s Role in Diesel Engine Efficiency

Cetane rating measures the combustion quality of diesel fuel, directly impacting engine start-up, combustion speed, and exhaust emissions. Higher cetane numbers indicate faster ignition and smoother engine operation, leading to improved fuel efficiency and reduced engine knocking in diesel engines. Optimizing cetane rating enhances diesel engine performance by promoting complete fuel combustion and lower pollutant output.

Measuring Octane and Cetane: Methods and Standards

Octane rating is measured using the Research Octane Number (RON) and Motor Octane Number (MON) methods, where fuel is tested in a standardized single-cylinder engine under controlled conditions to assess resistance to knocking. Cetane rating is determined by comparing fuel ignition delay to a reference fuel in a constant volume combustion chamber, with the cetane number indicating combustion speed and ignition quality. International standards such as ASTM D2699 for RON, ASTM D2700 for MON, and ASTM D613 for cetane number ensure consistent and reliable measurement of fuel performance characteristics.

Factors Influencing Octane and Cetane Ratings

Octane rating measures gasoline's resistance to knocking in spark-ignition engines, influenced by hydrocarbon molecular structure, blending components like aromatics and isoalkanes, and fuel additives. Cetane rating gauges diesel fuel ignition quality, affected by molecular weight, presence of paraffins, and sulfur content, which impact combustion delay and engine performance. Temperature, pressure, and injector design also play critical roles in optimizing both octane and cetane numbers for efficient fuel combustion.

Fuel Selection: Gasoline or Diesel Based on Rating Needs

Octane rating measures gasoline's resistance to knocking, making it crucial for selecting fuels in high-performance gasoline engines, while cetane rating indicates diesel fuel's ignition quality, essential for efficient combustion in diesel engines. Choosing gasoline with a higher octane rating prevents engine knock and improves power output, whereas diesel engines benefit from fuels with higher cetane numbers for smoother starts and better emission control. Understanding these ratings ensures optimal fuel selection, enhancing engine performance and longevity in vehicles designed for gasoline or diesel operation.

Impact of Engine Design on Fuel Rating Requirements

Engine design significantly influences the required fuel rating, with high-compression gasoline engines demanding higher octane ratings to prevent knocking and enable efficient combustion. Conversely, diesel engines rely on cetane ratings to measure ignition quality, where faster ignition in high-compression conditions improves performance and reduces emissions. Variable valve timing, turbocharging, and direct injection technologies modify combustion characteristics, thereby altering optimum octane or cetane requirements to maximize engine efficiency and longevity.

Future Trends: Advancements in Octane and Cetane Technology

Emerging innovations in fuel additives and combustion engine design are driving the evolution of octane and cetane ratings to optimize performance and emissions. Advanced catalysts and biofuel blends are enhancing octane numbers for gasoline engines while improving cetane values for diesel engines, promoting cleaner combustion and increased efficiency. Integration of AI-driven engine management systems enables precise fuel characterization, tailoring octane and cetane properties to future sustainable mobility demands.

Octane Rating vs Cetane Rating Infographic

cardiffo.com

cardiffo.com