Hand application in pet detailing allows for precise control, ensuring thorough cleaning of delicate areas such as eyes, ears, and paws. Machine application offers efficiency and consistency, ideal for covering larger surfaces quickly and reducing grooming time. Choosing between the two methods depends on the pet's temperament and specific grooming needs, balancing care quality with time management.

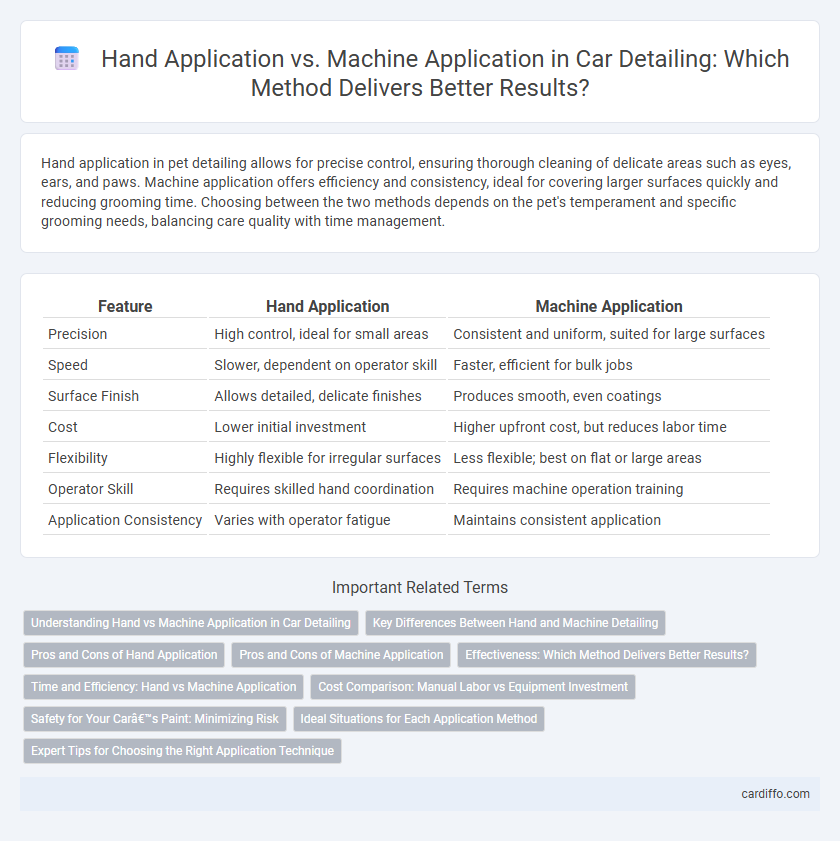

Table of Comparison

| Feature | Hand Application | Machine Application |

|---|---|---|

| Precision | High control, ideal for small areas | Consistent and uniform, suited for large surfaces |

| Speed | Slower, dependent on operator skill | Faster, efficient for bulk jobs |

| Surface Finish | Allows detailed, delicate finishes | Produces smooth, even coatings |

| Cost | Lower initial investment | Higher upfront cost, but reduces labor time |

| Flexibility | Highly flexible for irregular surfaces | Less flexible; best on flat or large areas |

| Operator Skill | Requires skilled hand coordination | Requires machine operation training |

| Application Consistency | Varies with operator fatigue | Maintains consistent application |

Understanding Hand vs Machine Application in Car Detailing

Hand application in car detailing offers precise control and better attention to intricate surfaces, ideal for delicate finishes and small areas. Machine application, such as orbital polishers, delivers consistent pressure and speed, reducing labor time and achieving uniform results on larger surfaces. Choosing between hand and machine application depends on the vehicle's condition, detailing goals, and desired efficiency.

Key Differences Between Hand and Machine Detailing

Hand application in detailing offers precision and control, allowing technicians to address intricate areas and customize pressure for delicate surfaces. Machine application enhances efficiency by covering large surfaces quickly and ensuring consistent polishing or waxing, reducing human fatigue during extensive jobs. Key differences include the level of accuracy, speed of execution, and suitability for either detailed touch-ups or full-panel treatments.

Pros and Cons of Hand Application

Hand application in detailing offers precise control and softer pressure, reducing the risk of damaging delicate surfaces or causing swirl marks. It allows for targeted treatment of tight spots and intricate areas that machines might miss, but it can be time-consuming and physically demanding for large surfaces. While hand application delivers meticulous results, it lacks the speed and consistency of machine methods, making it less efficient for extensive detailing jobs.

Pros and Cons of Machine Application

Machine application in detailing offers significant efficiency by covering large surfaces quickly and evenly, reducing labor time compared to hand application. It provides consistent pressure and speed, resulting in a uniform finish and improved product absorption, though the initial investment in equipment can be costly. However, machine application may pose a higher risk of surface damage if not operated properly, requiring skill and experience to avoid swirl marks or uneven coverage.

Effectiveness: Which Method Delivers Better Results?

Hand application in detailing provides precise control for intricate areas, ensuring meticulous cleaning and product distribution ideal for delicate surfaces. Machine application enhances efficiency and consistency, delivering powerful agitation that removes stubborn dirt and enhances polish absorption on large surfaces. Effectiveness depends on the task complexity; hand application excels in accuracy while machine methods boost speed and uniformity for comprehensive detailing.

Time and Efficiency: Hand vs Machine Application

Hand application in detailing typically requires more time and labor intensity compared to machine application, making it less efficient for large or multiple vehicles. Machine application, such as using rotary or dual-action polishers, significantly reduces polishing time while delivering consistent results and minimizing user fatigue. Efficiency gains from machine application translate to higher productivity and improved surface finish quality in professional detailing settings.

Cost Comparison: Manual Labor vs Equipment Investment

Hand application in detailing typically involves lower upfront costs due to minimal equipment investment but incurs higher ongoing expenses related to manual labor hours. Machine application requires a significant initial outlay for specialized equipment, yet it reduces labor costs by increasing efficiency and speed. Over time, the return on investment for machine application often outweighs manual labor expenses, especially for large-scale or frequent detailing projects.

Safety for Your Car’s Paint: Minimizing Risk

Hand application of car detailing products offers greater control and precision, significantly reducing the risk of paint damage such as swirl marks or scratches. Machine application, while efficient, requires proper technique and quality equipment to avoid excessive friction or heat buildup that can harm the clear coat. Choosing hand methods or using appropriate machine settings ensures safer results, preserving the integrity and longevity of your vehicle's paint.

Ideal Situations for Each Application Method

Hand application excels in precise, small-scale detailing projects where control and accuracy are paramount, such as intricate interior surfaces or tight engine components. Machine application is ideal for larger exterior surfaces requiring uniform coverage and efficiency, like full-body polishing and waxing on vehicles. Selecting the method depends on surface size, detail complexity, and desired finish quality.

Expert Tips for Choosing the Right Application Technique

Expert tips for choosing between hand application and machine application focus on surface type and product consistency. Hand application provides precision for intricate details and small areas, while machine application ensures even coverage and efficiency on large surfaces. Selecting the appropriate technique depends on the desired finish quality, time constraints, and material compatibility.

Hand Application vs Machine Application Infographic

cardiffo.com

cardiffo.com