Iron remover targets embedded iron particles and brake dust, dissolving them to prevent rust and paint damage, while tar remover specializes in breaking down sticky tar and asphalt residues without harming the vehicle's finish. Both products are essential in automotive detailing to maintain a clean and smooth surface, but selecting the right remover depends on the type of contamination present. Effective use of iron removers and tar removers ensures the paint remains free from stains and ready for polishing or waxing.

Table of Comparison

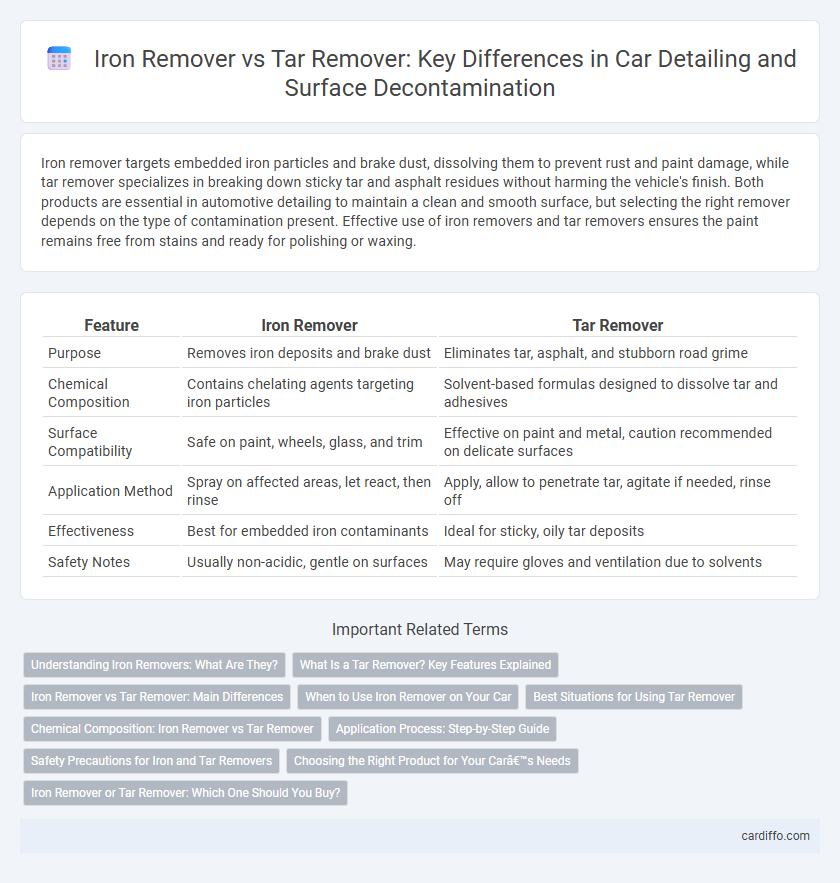

| Feature | Iron Remover | Tar Remover |

|---|---|---|

| Purpose | Removes iron deposits and brake dust | Eliminates tar, asphalt, and stubborn road grime |

| Chemical Composition | Contains chelating agents targeting iron particles | Solvent-based formulas designed to dissolve tar and adhesives |

| Surface Compatibility | Safe on paint, wheels, glass, and trim | Effective on paint and metal, caution recommended on delicate surfaces |

| Application Method | Spray on affected areas, let react, then rinse | Apply, allow to penetrate tar, agitate if needed, rinse off |

| Effectiveness | Best for embedded iron contaminants | Ideal for sticky, oily tar deposits |

| Safety Notes | Usually non-acidic, gentle on surfaces | May require gloves and ventilation due to solvents |

Understanding Iron Removers: What Are They?

Iron removers are specialized automotive detailing products designed to dissolve and eliminate iron particles embedded in paintwork, brake dust, and industrial fallout. These removers use chemical compounds such as chelating agents and acids to break down ferrous contaminants, reducing surface rust and preventing paint damage. Unlike tar removers that target sticky road grime and tar deposits, iron removers specifically address microscopic iron deposits to restore a smooth, clean finish.

What Is a Tar Remover? Key Features Explained

A tar remover is a specialized automotive detailing product designed to dissolve and safely lift tar, asphalt, and other stubborn road contaminants from vehicle surfaces without damaging the paint. Key features include strong solvent action for breaking down sticky residues, compatibility with various surfaces like paint, glass, and plastic, and fast-acting formulas that make cleaning efficient. Unlike iron removers, which target embedded iron particles and brake dust, tar removers focus specifically on softening and removing sticky tar deposits to restore a clean, smooth finish.

Iron Remover vs Tar Remover: Main Differences

Iron remover targets embedded iron particles and ferrous contaminants on vehicle surfaces, effectively dissolving rust and brake dust for a cleaner finish. Tar remover specializes in breaking down sticky tar, asphalt, and road grime that iron removers cannot dissolve, providing a smooth, residue-free surface. The main differences lie in their chemical formulations and targeted contaminants, with iron removers focusing on metallic particles and tar removers designed for sticky, oil-based residues.

When to Use Iron Remover on Your Car

Iron remover is essential after driving on railways, construction zones, or areas with heavy industrial fallout, as it targets embedded iron particles that traditional washes cannot eliminate. Use iron remover before tar remover to ensure all iron contaminants are dissolved, preventing scratches during subsequent cleaning. Applying iron remover regularly protects paintwork by neutralizing rust-causing iron deposits and maintains a smooth surface for waxing or sealing.

Best Situations for Using Tar Remover

Tar remover is best suited for eliminating stubborn tree sap, asphalt deposits, and industrial contaminants that standard iron removers cannot effectively dissolve. Its powerful solvents target sticky residues on paintwork, helping restore smooth and clean surfaces without damaging the clear coat. Use tar remover specifically when facing heavy, viscous tar stains or sticky debris after road construction or winter salting.

Chemical Composition: Iron Remover vs Tar Remover

Iron removers typically contain chelating agents such as ethylenediaminetetraacetic acid (EDTA) or hydrofluoric acid derivatives designed to bind and dissolve iron particles embedded in surfaces. Tar removers primarily consist of strong solvents like naphtha or citrus-based compounds that break down hydrocarbon-based adhesives and tar residues. The distinct chemical compositions target specific contaminants, with iron removers focusing on metallic oxidation compounds and tar removers effectively dissolving sticky, oily substances.

Application Process: Step-by-Step Guide

To apply iron remover, start by rinsing the vehicle to remove loose dirt, then spray the product evenly over the affected areas, allowing it to dwell for 3-5 minutes until contaminants visibly react, followed by rinsing thoroughly. For tar remover, apply directly onto the tar spots using a microfiber cloth or applicator, gently agitate to dissolve the residue, then wipe clean and wash the area with soap and water to remove any remaining product. Both products require following with a full wash and drying to ensure complete contaminant removal and protect the paint surface.

Safety Precautions for Iron and Tar Removers

Iron removers contain strong acids like hydrochloric acid, requiring the use of gloves, protective eyewear, and well-ventilated areas to prevent skin burns and respiratory irritation. Tar removers typically involve solvents such as kerosene or citrus-based chemicals, necessitating caution to avoid skin contact, inhalation of fumes, and ensuring fire safety due to flammability. Always read product labels carefully and conduct a spot test to avoid damage to vehicle paint or finishes.

Choosing the Right Product for Your Car’s Needs

Iron remover effectively dissolves embedded iron particles from brake dust and rail dust, preventing paint contamination and corrosion. Tar remover targets stubborn tar spots and asphalt residues that traditional washing cannot eliminate, ensuring a smooth, clean surface. Selecting the right product depends on identifying the specific contaminants on your vehicle's exterior to enhance cleaning efficiency and protect the paintwork.

Iron Remover or Tar Remover: Which One Should You Buy?

Iron remover targets and dissolves iron particles and brake dust embedded in paintwork, preventing rust and staining, while tar remover is designed to break down sticky tar and asphalt deposits that cling to vehicle surfaces. Choosing between iron remover and tar remover depends on the type of contaminant present; for vehicles frequently driven on highways, tar remover is essential, whereas iron remover benefits those exposed to industrial fallout or railway environments. For comprehensive detailing, many detailers recommend having both products on hand to ensure effective removal of these distinct contaminants.

Iron Remover vs Tar Remover Infographic

cardiffo.com

cardiffo.com