Clay barring physically removes surface contaminants such as paint overspray, sap, and embedded dirt, restoring a smooth finish by lifting particles from the clear coat. Iron decontamination specifically targets iron deposits like brake dust and rail dust using chemical iron removers that dissolve embedded metallic particles without abrasion. Combining both methods ensures a thoroughly clean surface, enhancing paint clarity and preparation for polishing or sealing in detailing.

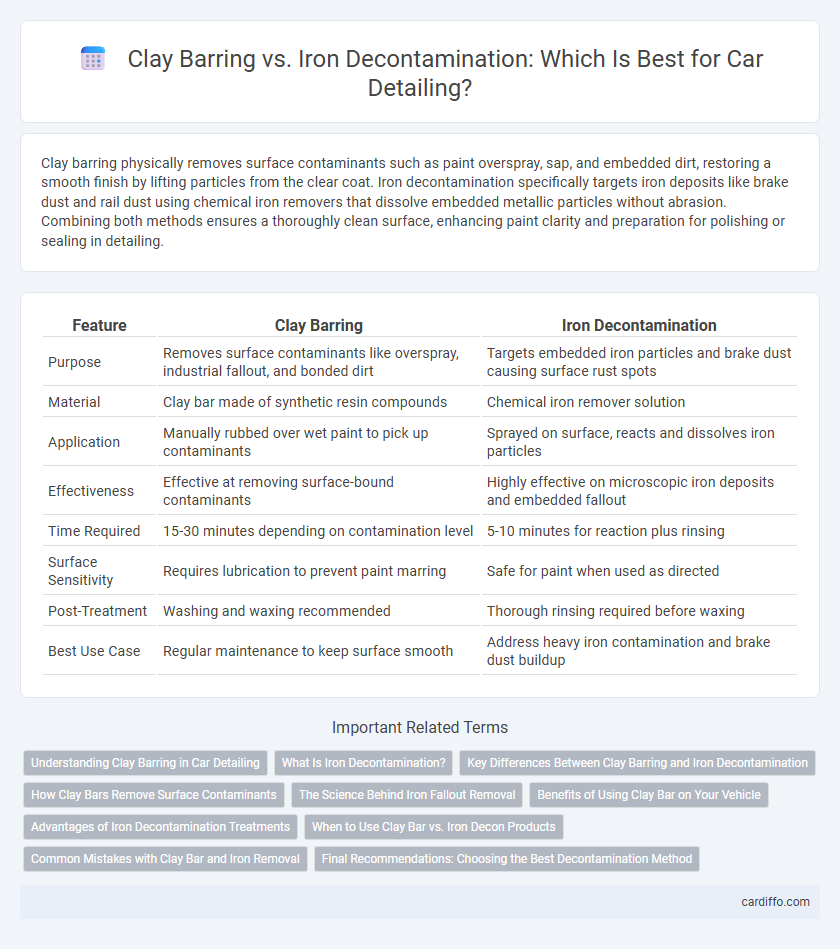

Table of Comparison

| Feature | Clay Barring | Iron Decontamination |

|---|---|---|

| Purpose | Removes surface contaminants like overspray, industrial fallout, and bonded dirt | Targets embedded iron particles and brake dust causing surface rust spots |

| Material | Clay bar made of synthetic resin compounds | Chemical iron remover solution |

| Application | Manually rubbed over wet paint to pick up contaminants | Sprayed on surface, reacts and dissolves iron particles |

| Effectiveness | Effective at removing surface-bound contaminants | Highly effective on microscopic iron deposits and embedded fallout |

| Time Required | 15-30 minutes depending on contamination level | 5-10 minutes for reaction plus rinsing |

| Surface Sensitivity | Requires lubrication to prevent paint marring | Safe for paint when used as directed |

| Post-Treatment | Washing and waxing recommended | Thorough rinsing required before waxing |

| Best Use Case | Regular maintenance to keep surface smooth | Address heavy iron contamination and brake dust buildup |

Understanding Clay Barring in Car Detailing

Clay barring in car detailing effectively removes embedded contaminants like industrial fallout, brake dust, and tar from the vehicle's paint surface, restoring smoothness and enhancing gloss. Unlike iron decontamination, which specifically targets iron particles using chemical solutions, clay barring physically lifts a broader range of pollutants, including organic residues and overspray. This technique improves paint adhesion for subsequent polishing and waxing, ensuring a comprehensive surface preparation for long-lasting protection.

What Is Iron Decontamination?

Iron decontamination is a specialized detailing process aimed at removing iron particles embedded in a vehicle's paintwork, which conventional washing cannot eliminate. This process uses chemical decontaminants, often iron removers, that react with iron deposits, turning them into a removable state without damaging the surface. Iron decontamination is essential for maintaining paint clarity, preventing rust stains, and preparing the vehicle for further treatments like polishing or ceramic coating.

Key Differences Between Clay Barring and Iron Decontamination

Clay barring effectively removes surface contaminants such as overspray, tar, and industrial fallout by physically lifting them from the paint, while iron decontamination specifically targets embedded iron particles and brake dust using chemical agents like iron removers. Clay bars require lubrication and manual effort to glide over the surface without scratching, whereas iron decontamination involves applying a reactive liquid that changes color when it dissolves iron deposits. The main difference lies in their approach: clay barring is a mechanical process suitable for general decontamination, while iron decontamination is a chemical method focused on eliminating microscopic metallic contaminants deeply embedded in the paintwork.

How Clay Bars Remove Surface Contaminants

Clay bars remove surface contaminants by physically lifting bonded particles such as industrial fallout, brake dust, and road tar embedded in the clear coat. The soft, pliable clay shears away these impurities without damaging the paint, restoring a smooth and clean surface. Unlike iron decontamination that chemically dissolves iron particles, clay barring provides a tactile method to eliminate a broader range of bonded contaminants.

The Science Behind Iron Fallout Removal

Iron fallout removal relies on chemical reactions that break down iron particles bonded to the paint surface, with iron decontamination products typically containing iron-specific chelating agents that dissolve embedded iron oxides. Clay barring physically removes contaminants through the use of a malleable clay compound that picks up surface impurities without chemically altering iron deposits. While clay barring is effective for general contamination, iron decontamination targets bonded iron particles at a molecular level, offering a more thorough solution for iron fallout removal.

Benefits of Using Clay Bar on Your Vehicle

Clay bar treatment effectively removes surface contaminants like industrial fallout, brake dust, and tar that traditional washing cannot eliminate, restoring a smooth and clean paint finish. This process enhances paint clarity and gloss by eliminating embedded particles that cause surface imperfections, improving the vehicle's overall appearance. Using a clay bar also promotes better paint protection adherence, allowing waxes and sealants to bond more effectively and extend their longevity.

Advantages of Iron Decontamination Treatments

Iron decontamination treatments effectively remove embedded iron particles from painted surfaces, preventing long-term staining and corrosion more efficiently than clay barring. These treatments use chemical agents that dissolve iron contaminants at a molecular level, ensuring deeper cleaning without the risk of surface marring. Iron decontamination extends paint longevity and enhances overall finish clarity by targeting contaminants that clay bars cannot eliminate.

When to Use Clay Bar vs. Iron Decon Products

Clay bars excel at removing surface contaminants like paint overspray, tree sap, and industrial fallout that traditional washing can't eliminate. Iron decontamination products specifically target embedded iron particles such as brake dust and rail dust, dissolving them chemically without abrasion. Use a clay bar for broad surface decontamination during regular maintenance, and opt for iron decontamination when stubborn ferrous contaminants cause visible rust spots or paint discoloration.

Common Mistakes with Clay Bar and Iron Removal

Common mistakes with clay bar detailing include using excessive pressure, which can cause surface scratches, and failing to properly lubricate the paint, leading to marring. Iron decontamination errors often involve neglecting to thoroughly spray iron remover on all affected areas or not allowing sufficient dwell time for chemical reactions. Combining improper clay bar usage with inadequate iron removal can result in incomplete contaminant removal and compromised paint finish.

Final Recommendations: Choosing the Best Decontamination Method

Clay barring effectively removes surface contaminants like overspray and industrial fallout, making it ideal for light to moderate decontamination. Iron decontamination targets embedded iron particles and brake dust, providing deeper cleaning for heavily contaminated surfaces. For optimal results, combine both methods: start with iron decontamination to dissolve stubborn iron deposits, then proceed with clay barring to achieve a flawlessly smooth finish.

Clay barring vs Iron decontamination Infographic

cardiffo.com

cardiffo.com