Hand polishing offers precise control and is ideal for delicate surfaces, allowing for targeted removal of minor imperfections without risking damage. Machine polishing is more efficient for larger areas, providing consistent abrasion and faster results suitable for heavy oxidation or scratches. Choosing between hand and machine polishing depends on the extent of surface damage and desired finish quality.

Table of Comparison

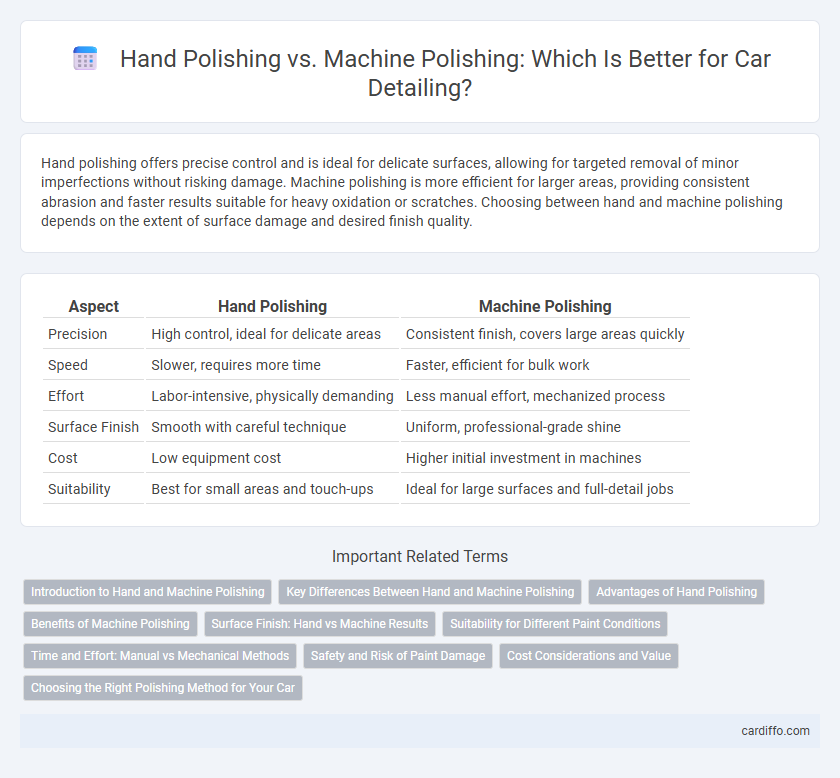

| Aspect | Hand Polishing | Machine Polishing |

|---|---|---|

| Precision | High control, ideal for delicate areas | Consistent finish, covers large areas quickly |

| Speed | Slower, requires more time | Faster, efficient for bulk work |

| Effort | Labor-intensive, physically demanding | Less manual effort, mechanized process |

| Surface Finish | Smooth with careful technique | Uniform, professional-grade shine |

| Cost | Low equipment cost | Higher initial investment in machines |

| Suitability | Best for small areas and touch-ups | Ideal for large surfaces and full-detail jobs |

Introduction to Hand and Machine Polishing

Hand polishing involves manually applying polish using cloths or pads, allowing for precise control and careful attention to delicate surfaces. Machine polishing employs rotary or dual-action polishers powered by electricity to efficiently remove imperfections and restore shine on larger areas. Both methods target surface defects like swirls, oxidation, and scratches but differ in speed, consistency, and operator skill requirements.

Key Differences Between Hand and Machine Polishing

Hand polishing offers precise control and is ideal for small, intricate surfaces but requires significant time and effort. Machine polishing uses powered tools to achieve faster, more uniform results on larger areas, reducing labor intensity. Key differences include speed, consistency, surface area coverage, and operator skill level needed.

Advantages of Hand Polishing

Hand polishing offers unparalleled control and precision, allowing detailers to target specific areas with delicate finishes that reduce the risk of paint swirl marks. It provides a more tactile feedback, enhancing the ability to adjust pressure and technique based on the surface condition, which is often essential for restoring vintage or high-value vehicles. The process is highly versatile, ideal for intricate surfaces and edges that machines may not effectively reach or handle without causing damage.

Benefits of Machine Polishing

Machine polishing delivers a consistently higher level of finish with greater efficiency and speed compared to hand polishing, significantly reducing labor time. It provides a more uniform surface by evenly distributing pressure and polishing compounds, minimizing the risk of human error and swirl marks. Advanced polishing machines also offer adjustable speed and torque settings, allowing for precise control tailored to different paint types and conditions.

Surface Finish: Hand vs Machine Results

Hand polishing delivers a finer, more controlled surface finish by allowing detailed attention to small imperfections and achieving a deep gloss on delicate or irregular surfaces. Machine polishing produces consistent, uniform results across larger areas, efficiently removing scratches and oxidation but may risk over-polishing or heat damage if not carefully managed. For optimal surface finish, combining hand polishing for intricate spots with machine polishing for broad surfaces yields the best overall shine and smoothness in automotive detailing.

Suitability for Different Paint Conditions

Hand polishing offers precise control ideal for delicate or older paint with minor imperfections, ensuring minimal risk of damage. Machine polishing delivers consistent power suitable for moderate to heavily oxidized or scratched paint, significantly reducing correction time. Choosing between hand and machine polishing depends on the paint's condition and desired level of surface restoration.

Time and Effort: Manual vs Mechanical Methods

Hand polishing demands significant time and physical effort, relying on manual control to achieve precise results, often requiring multiple passes for a flawless finish. Machine polishing drastically reduces labor intensity and complete polishing time due to consistent power and speed, enabling faster correction of paint imperfections. Choosing between manual and mechanical methods depends on the job size, desired finish quality, and available resources, with machines favored for efficiency and hands preferred for delicate touch-ups.

Safety and Risk of Paint Damage

Hand polishing minimizes the risk of paint damage by allowing precise control and gentle pressure, reducing the chances of swirl marks and clear coat thinning. Machine polishing, while faster and effective for heavy imperfections, carries a higher risk of burning the paint or creating holograms if not used properly. Proper technique and experience are essential to ensure safety and protect the vehicle's paint integrity during either polishing method.

Cost Considerations and Value

Hand polishing generally involves lower upfront costs due to minimal equipment requirements but demands more time and skilled labor, increasing overall expense for large or frequent jobs. Machine polishing, while requiring a higher initial investment in tools and maintenance, offers faster completion and more consistent results, enhancing long-term value for professional detailers. Evaluating the balance between labor intensity, tool costs, and desired finish quality is essential for determining the most cost-effective polishing method.

Choosing the Right Polishing Method for Your Car

Hand polishing offers precise control and is ideal for delicate surfaces or small areas, ensuring a flawless finish without risking paint damage. Machine polishing provides faster, more consistent results suitable for larger surfaces and moderate to heavy oxidation or scratches. Selecting the right method depends on your car's paint condition, size, and your experience level to achieve optimal results without compromising the finish.

Hand Polishing vs Machine Polishing Infographic

cardiffo.com

cardiffo.com