A Battery Management System (BMS) provides advanced monitoring and control over battery performance, including cell balancing, state-of-charge estimation, and protection against overcharging or deep discharge. In contrast, a Protection Circuit Module (PCM) primarily safeguards batteries by preventing overcurrent, short circuits, and overvoltage without active management features. Choosing between BMS and PCM depends on the complexity and safety requirements of the battery application, with BMS offering comprehensive battery health management and PCM providing basic protection functions.

Table of Comparison

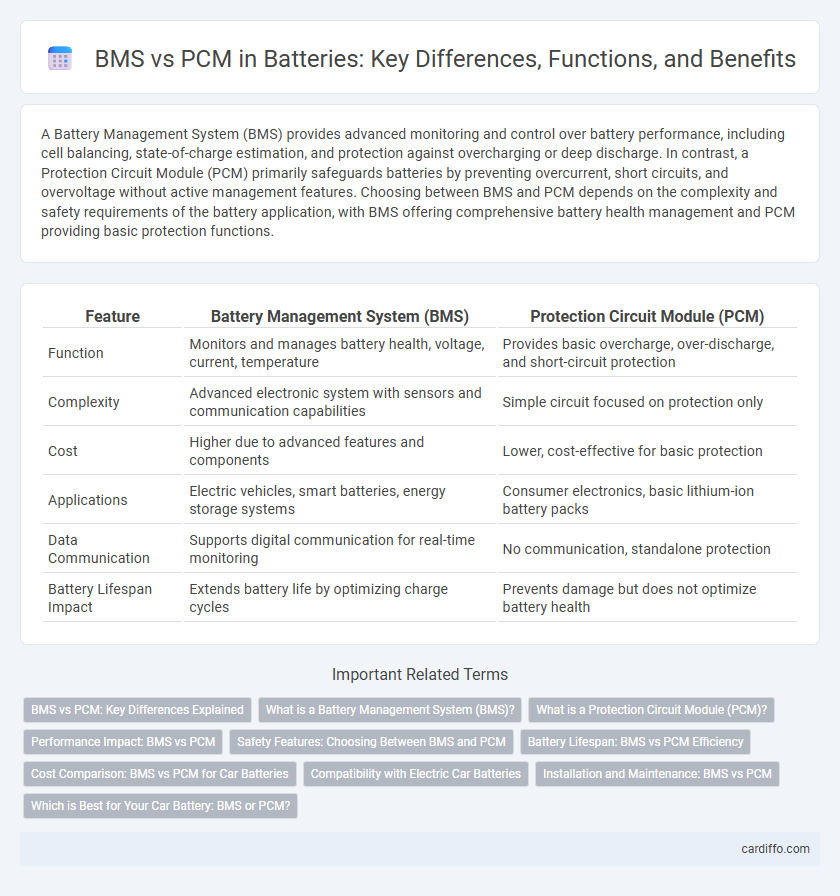

| Feature | Battery Management System (BMS) | Protection Circuit Module (PCM) |

|---|---|---|

| Function | Monitors and manages battery health, voltage, current, temperature | Provides basic overcharge, over-discharge, and short-circuit protection |

| Complexity | Advanced electronic system with sensors and communication capabilities | Simple circuit focused on protection only |

| Cost | Higher due to advanced features and components | Lower, cost-effective for basic protection |

| Applications | Electric vehicles, smart batteries, energy storage systems | Consumer electronics, basic lithium-ion battery packs |

| Data Communication | Supports digital communication for real-time monitoring | No communication, standalone protection |

| Battery Lifespan Impact | Extends battery life by optimizing charge cycles | Prevents damage but does not optimize battery health |

BMS vs PCM: Key Differences Explained

Battery Management System (BMS) and Protection Circuit Module (PCM) serve distinct roles in battery safety and performance, with BMS offering comprehensive monitoring of individual cell voltages, temperatures, and state of charge, while PCM primarily provides basic overcharge, over-discharge, and short-circuit protection. BMS enhances battery longevity and efficiency through active balancing and complex data analysis, whereas PCM acts as a passive safeguard to prevent immediate electrical faults. Understanding these differences is crucial for selecting appropriate battery protection tailored to specific applications such as electric vehicles or consumer electronics.

What is a Battery Management System (BMS)?

A Battery Management System (BMS) is an electronic control unit designed to monitor and manage rechargeable battery cells to ensure safety, performance, and longevity. It regulates charging and discharging processes, balances cell voltages, and protects against overcurrent, overvoltage, undervoltage, and overheating conditions. Unlike a Protection Circuit Module (PCM), a BMS provides comprehensive real-time data, fault diagnostics, and advanced features essential for complex battery packs in electric vehicles and energy storage systems.

What is a Protection Circuit Module (PCM)?

A Protection Circuit Module (PCM) is an essential component in lithium-ion battery packs designed to prevent overcharging, over-discharging, and short circuits, ensuring safety and longevity. It monitors voltage and current levels, disconnecting the battery when unsafe conditions are detected to avoid damage and potential hazards. PCM differs from Battery Management Systems (BMS) by offering basic protection functions without advanced features such as cell balancing or state-of-charge estimation.

Performance Impact: BMS vs PCM

Battery Management Systems (BMS) offer advanced performance optimization by continuously monitoring cell voltage, temperature, and state of charge, ensuring balanced charging and preventing overcharge or deep discharge. In contrast, Protection Circuit Modules (PCM) provide basic safety functions such as overcurrent and short-circuit protection but lack comprehensive data analysis and adaptive control. The integration of a BMS significantly enhances battery lifespan, efficiency, and reliability, while PCM serves as a minimal safeguard primarily for safety without performance optimization.

Safety Features: Choosing Between BMS and PCM

Battery Management Systems (BMS) provide comprehensive safety features by continuously monitoring cell voltages, temperatures, and current flow to prevent overcharging, overheating, and short circuits. Protection Circuit Modules (PCM) offer basic safety functions such as overcharge, over-discharge, and short-circuit protection but lack real-time monitoring and balancing capabilities. For enhanced battery longevity and advanced safety assurance, BMS is the preferred choice over PCM in modern battery applications.

Battery Lifespan: BMS vs PCM Efficiency

Battery Management Systems (BMS) enhance battery lifespan by precisely monitoring cell voltage, temperature, and current to prevent overcharging and deep discharging, leading to improved efficiency and safety. In contrast, Protection Circuit Modules (PCM) provide basic safeguards against short circuits and overcurrent but lack advanced balancing and thermal management features, resulting in comparatively lower efficiency in extending battery life. Implementing a BMS significantly optimizes battery performance and durability over traditional PCM solutions.

Cost Comparison: BMS vs PCM for Car Batteries

Battery Management Systems (BMS) typically cost more than Protection Circuit Modules (PCM) due to their advanced features like cell balancing and state-of-charge monitoring, which enhance battery lifespan and safety. PCM offers a lower-cost solution by providing essential protection functions such as overcurrent, short circuit, and overvoltage protection without complex data monitoring. When choosing between BMS and PCM for car batteries, manufacturers balance budget constraints with the need for comprehensive battery health management and safety.

Compatibility with Electric Car Batteries

Battery Management Systems (BMS) are specifically designed for electric car batteries, offering precise monitoring and balancing of individual cells to enhance safety and longevity. Protection Circuit Modules (PCM) provide basic overcharge, over-discharge, and short circuit protection but lack the advanced communication and diagnostic features required for modern electric vehicle battery packs. Compatibility with electric car batteries favors BMS due to their ability to manage complex lithium-ion chemistries and support high-voltage configurations typical in electric vehicles.

Installation and Maintenance: BMS vs PCM

Battery Management System (BMS) requires complex installation involving sensors and communication modules to monitor cell voltage, temperature, and current in real-time, ensuring balanced charging and enhanced safety. In contrast, a Protection Circuit Module (PCM) offers simpler installation with basic overcharge, over-discharge, and short-circuit protection, requiring minimal wiring and lower maintenance. Maintenance of BMS is more intensive due to firmware updates and sensor calibration, whereas PCM demands less frequent checks, simplifying upkeep in low-cost battery applications.

Which is Best for Your Car Battery: BMS or PCM?

Battery Management Systems (BMS) offer comprehensive monitoring and control over individual cell voltages, temperature, and state of charge, providing enhanced safety and longevity for your car battery. Power Control Modules (PCM) primarily regulate overall battery power delivery and charging, focusing on system integration rather than detailed cell management. For optimal battery performance and protection, especially in electric vehicles, a BMS is generally the superior choice.

BMS vs PCM Infographic

cardiffo.com

cardiffo.com