Positive ground systems connect the battery's positive terminal to the vehicle's chassis, while negative ground systems link the negative terminal instead. Modern vehicles predominantly use negative ground for better safety and compatibility with electronic components. Understanding the difference ensures proper battery installation and prevents electrical system damage.

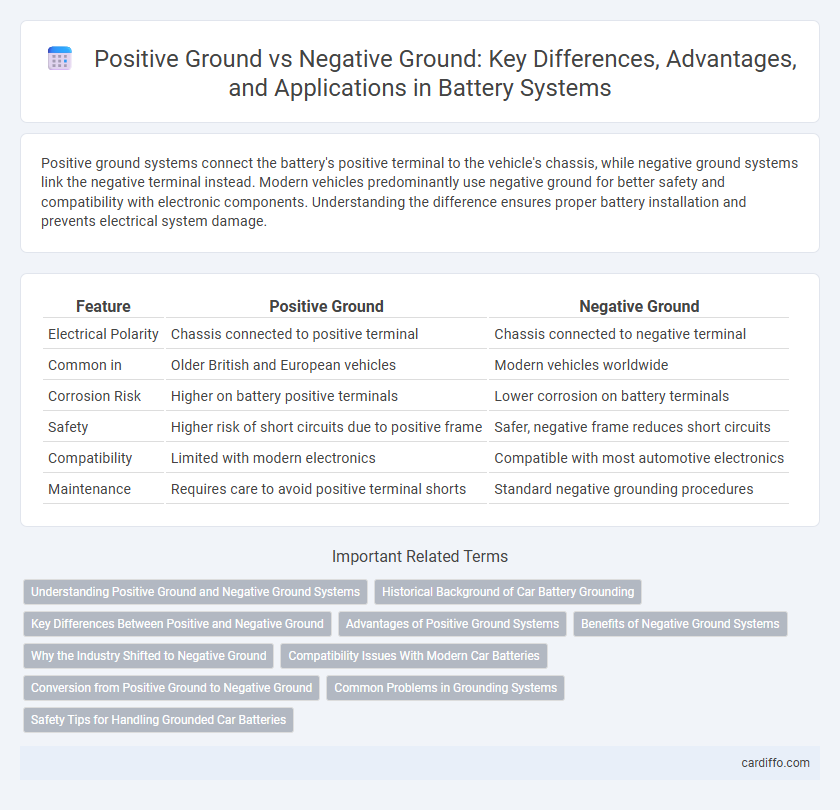

Table of Comparison

| Feature | Positive Ground | Negative Ground |

|---|---|---|

| Electrical Polarity | Chassis connected to positive terminal | Chassis connected to negative terminal |

| Common in | Older British and European vehicles | Modern vehicles worldwide |

| Corrosion Risk | Higher on battery positive terminals | Lower corrosion on battery terminals |

| Safety | Higher risk of short circuits due to positive frame | Safer, negative frame reduces short circuits |

| Compatibility | Limited with modern electronics | Compatible with most automotive electronics |

| Maintenance | Requires care to avoid positive terminal shorts | Standard negative grounding procedures |

Understanding Positive Ground and Negative Ground Systems

Positive ground systems connect the vehicle's chassis to the battery's positive terminal, a design commonly used in older vehicles, contrasting with negative ground systems which link the chassis to the battery's negative terminal. Understanding these configurations is crucial for proper battery installation and electrical system compatibility to prevent damage. Negative ground systems dominate modern vehicles due to improved corrosion resistance and compatibility with electronic components.

Historical Background of Car Battery Grounding

Early automotive electrical systems primarily used positive ground configurations, reflecting the technology and materials available in the early 20th century. Negative ground systems emerged mid-century as electrical components and ignition systems evolved, eventually becoming the global standard due to improved safety and compatibility with modern electronics. Understanding the historical shift from positive to negative grounding helps clarify modern automotive battery design and troubleshooting practices.

Key Differences Between Positive and Negative Ground

Positive ground systems connect the battery's positive terminal to the vehicle chassis, while negative ground systems connect the negative terminal to the chassis, influencing electrical polarity and component compatibility. Positive ground configurations were common in older vehicles but are less efficient and more prone to corrosion compared to the widespread negative ground systems used in modern automotive design. Understanding these differences is crucial for proper battery installation, electrical system maintenance, and preventing damage to sensitive electronic components.

Advantages of Positive Ground Systems

Positive ground systems offer advantages such as reduced corrosion on metal chassis due to the grounding of the vehicle frame to the positive terminal, which decreases electrochemical reactions. These systems can simplify wiring and maintenance in older vehicles by providing a common reference point that is less prone to voltage fluctuations. Positive grounding also helps protect sensitive electronic components by minimizing potential reverse polarity damage in certain automotive electrical setups.

Benefits of Negative Ground Systems

Negative ground systems enhance electrical safety by reducing the risk of corrosion in vehicle components, improving overall durability. These systems ensure better compatibility with modern electronic devices by providing a stable reference voltage, which optimizes performance and efficiency. Negative grounding also simplifies the installation process for accessories and diagnostic tools, leading to more reliable and consistent electrical operation.

Why the Industry Shifted to Negative Ground

The automotive industry shifted from positive ground to negative ground due to improved electrical system reliability and compatibility with modern electronics. Negative ground systems reduce corrosion and electrical interference, enhancing battery and vehicle component lifespan. This shift also supports standardized wiring and safer current flow, aligning with advancements in alternator and ignition technologies.

Compatibility Issues With Modern Car Batteries

Positive ground electrical systems are largely incompatible with modern car batteries designed for negative ground configurations, leading to potential damage to the vehicle's electronic components. Modern vehicles use negative ground systems to improve safety and reduce corrosion, so installing a positive ground battery can cause electrical shorts and malfunction of onboard computers. Ensuring the battery matches the vehicle's grounding system is crucial for maintaining optimal performance and avoiding costly repairs.

Conversion from Positive Ground to Negative Ground

Converting a positive ground battery system to a negative ground involves reversing the polarity connections, where the vehicle's chassis changes from being connected to the positive terminal to the negative terminal. This conversion requires replacing or modifying electrical components such as the generator, voltage regulator, and ignition coil to be compatible with a negative ground system. Ensuring proper insulation and verifying polarity with a multimeter prevents electrical damage and guarantees safe, efficient battery performance after the conversion.

Common Problems in Grounding Systems

Positive ground systems often experience corrosion at grounding points due to reversed polarity causing accelerated oxidation on metal components. Negative ground systems can suffer from poor connectivity and voltage drop if grounding cables are improperly sized or damaged, leading to inconsistent electrical performance. Both systems require regular inspection of terminals and wires to prevent issues like loose connections, which can result in intermittent faults and starting problems.

Safety Tips for Handling Grounded Car Batteries

When handling grounded car batteries, always verify the ground type--positive or negative--to prevent electrical shorts and sparks. Use insulated tools and wear protective gloves to safeguard against accidental contact with terminals. Ensure the car's ignition is off before disconnecting the battery to minimize shock hazards and potential damage to the vehicle's electrical system.

Positive Ground vs Negative Ground Infographic

cardiffo.com

cardiffo.com