Scheduled maintenance for service pets involves regular check-ups and preventative care such as vaccinations, grooming, and health monitoring to ensure their optimal well-being and performance. Corrective maintenance addresses unexpected health issues or injuries that require immediate veterinary attention and treatment to restore the pet's functionality. Prioritizing scheduled maintenance helps minimize the need for corrective actions, promoting consistent service animal reliability.

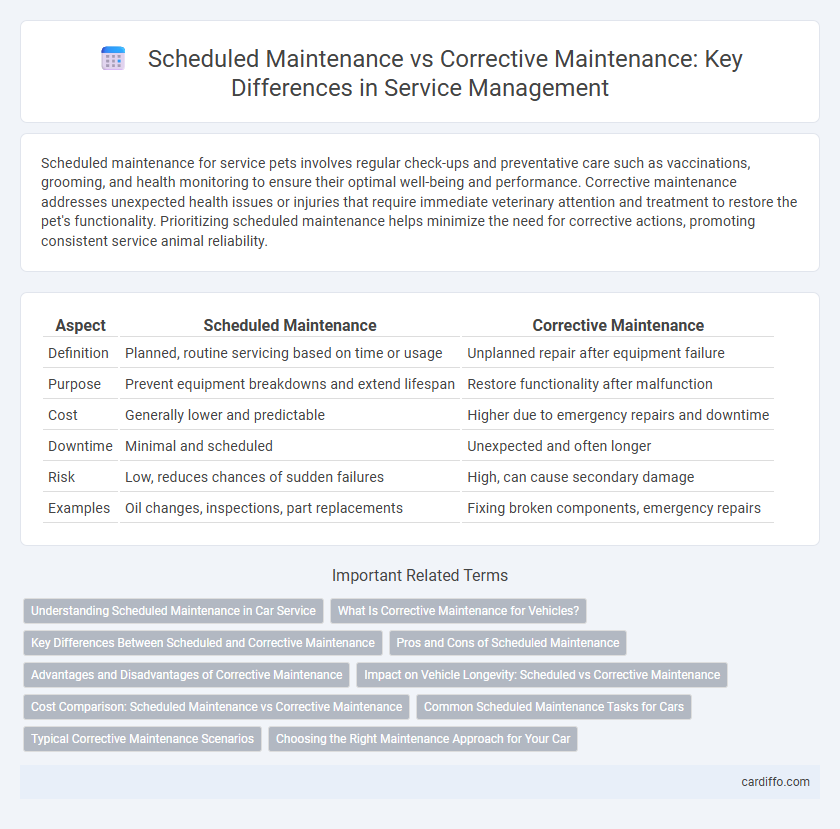

Table of Comparison

| Aspect | Scheduled Maintenance | Corrective Maintenance |

|---|---|---|

| Definition | Planned, routine servicing based on time or usage | Unplanned repair after equipment failure |

| Purpose | Prevent equipment breakdowns and extend lifespan | Restore functionality after malfunction |

| Cost | Generally lower and predictable | Higher due to emergency repairs and downtime |

| Downtime | Minimal and scheduled | Unexpected and often longer |

| Risk | Low, reduces chances of sudden failures | High, can cause secondary damage |

| Examples | Oil changes, inspections, part replacements | Fixing broken components, emergency repairs |

Understanding Scheduled Maintenance in Car Service

Scheduled maintenance in car service involves routine inspections and part replacements based on the manufacturer's recommended timeline or mileage, aiming to prevent major breakdowns and enhance vehicle longevity. This proactive approach includes oil changes, brake checks, and fluid top-ups, ensuring optimal performance and safety. Understanding scheduled maintenance helps car owners avoid unexpected repairs and maintain warranty compliance.

What Is Corrective Maintenance for Vehicles?

Corrective maintenance for vehicles involves repairing or restoring components after a fault or failure has occurred, ensuring the vehicle returns to proper working condition. It contrasts with scheduled maintenance, which is performed proactively at regular intervals to prevent breakdowns. This approach focuses on addressing unexpected issues promptly to minimize downtime and restore functionality efficiently.

Key Differences Between Scheduled and Corrective Maintenance

Scheduled maintenance involves planned, routine inspections and servicing to prevent equipment failure, improving reliability and reducing downtime. Corrective maintenance occurs after equipment failure or malfunction, focusing on diagnosing and repairing issues to restore normal operation. Key differences include timing, with scheduled maintenance being proactive and corrective maintenance reactive, and cost implications, as scheduled maintenance generally reduces long-term expenses by avoiding unexpected breakdowns.

Pros and Cons of Scheduled Maintenance

Scheduled maintenance enhances equipment reliability by preventing unexpected breakdowns and extending asset lifespan through regular inspections and servicing. However, it can lead to higher upfront costs and potential downtime since maintenance occurs regardless of actual equipment condition. This proactive approach reduces emergency repairs but may result in unnecessary part replacements or labor when issues are not imminent.

Advantages and Disadvantages of Corrective Maintenance

Corrective maintenance addresses equipment failures after they occur, minimizing downtime and focusing resources only when issues arise, which can reduce immediate maintenance costs. However, unplanned repairs often lead to longer downtime, higher labor costs, and potential damage escalation, impacting overall productivity and operational efficiency. The unpredictability of corrective maintenance increases risk and can result in costly emergency interventions compared to more proactive approaches like scheduled maintenance.

Impact on Vehicle Longevity: Scheduled vs Corrective Maintenance

Scheduled maintenance, performed at regular intervals based on manufacturer recommendations, significantly enhances vehicle longevity by preventing major component failures and ensuring optimal performance. Corrective maintenance, carried out only after a breakdown or performance issue, often leads to increased wear and tear, reducing the overall lifespan of critical vehicle systems. Proactive scheduled servicing minimizes costly repairs and extends engine, transmission, and brake system durability compared to reactive corrective repairs.

Cost Comparison: Scheduled Maintenance vs Corrective Maintenance

Scheduled maintenance typically incurs lower overall costs by preventing major equipment failures and extending asset lifespan, reducing expensive emergency repairs and downtime. Corrective maintenance often leads to higher expenses due to unplanned labor, expedited parts shipping, and operational disruptions causing productivity losses. Investing in scheduled maintenance optimizes budget allocation by minimizing unexpected costs associated with corrective actions.

Common Scheduled Maintenance Tasks for Cars

Common scheduled maintenance tasks for cars include oil changes, tire rotations, brake inspections, and fluid level checks, all designed to prevent breakdowns and extend vehicle lifespan. Regularly replacing air filters, inspecting belts and hoses, and performing battery tests are essential to ensure optimal engine performance and safety. These proactive measures reduce unexpected repair costs and maintain the car's resale value by addressing potential issues before they escalate.

Typical Corrective Maintenance Scenarios

Typical corrective maintenance scenarios involve unexpected equipment failures that disrupt operations, requiring immediate repair to restore functionality. These include breakdowns of machinery, system malfunctions, and component wear that cause unplanned downtime. Effective corrective maintenance prioritizes rapid diagnosis and resolution to minimize impact on productivity.

Choosing the Right Maintenance Approach for Your Car

Scheduled maintenance follows a predetermined plan based on time or mileage to prevent breakdowns and keep your car running efficiently, while corrective maintenance addresses specific issues as they arise. Selecting the right maintenance approach depends on factors like your vehicle's age, usage frequency, and manufacturer recommendations. Regularly performing scheduled maintenance can reduce the need for costly corrective repairs by identifying potential problems early.

scheduled maintenance vs corrective maintenance Infographic

cardiffo.com

cardiffo.com