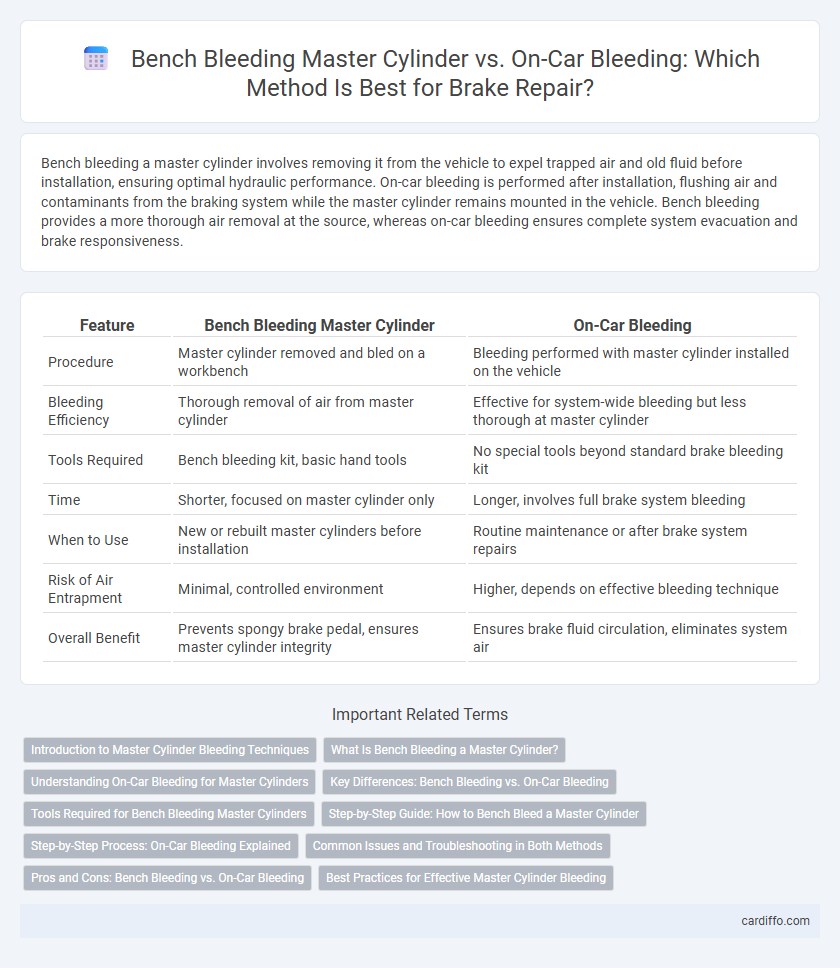

Bench bleeding a master cylinder involves removing it from the vehicle to expel trapped air and old fluid before installation, ensuring optimal hydraulic performance. On-car bleeding is performed after installation, flushing air and contaminants from the braking system while the master cylinder remains mounted in the vehicle. Bench bleeding provides a more thorough air removal at the source, whereas on-car bleeding ensures complete system evacuation and brake responsiveness.

Table of Comparison

| Feature | Bench Bleeding Master Cylinder | On-Car Bleeding |

|---|---|---|

| Procedure | Master cylinder removed and bled on a workbench | Bleeding performed with master cylinder installed on the vehicle |

| Bleeding Efficiency | Thorough removal of air from master cylinder | Effective for system-wide bleeding but less thorough at master cylinder |

| Tools Required | Bench bleeding kit, basic hand tools | No special tools beyond standard brake bleeding kit |

| Time | Shorter, focused on master cylinder only | Longer, involves full brake system bleeding |

| When to Use | New or rebuilt master cylinders before installation | Routine maintenance or after brake system repairs |

| Risk of Air Entrapment | Minimal, controlled environment | Higher, depends on effective bleeding technique |

| Overall Benefit | Prevents spongy brake pedal, ensures master cylinder integrity | Ensures brake fluid circulation, eliminates system air |

Introduction to Master Cylinder Bleeding Techniques

Bench bleeding master cylinders involves securing the cylinder on a workbench and manually cycling brake fluid through it to remove air before installation, ensuring optimal hydraulic pressure. On-car bleeding requires the master cylinder to be bled while installed, allowing for system-wide air removal through pressure or vacuum methods. Both techniques are crucial for maintaining brake system integrity and preventing spongy brake pedal feel.

What Is Bench Bleeding a Master Cylinder?

Bench bleeding a master cylinder is the process of removing air from the hydraulic brake system by manually cycling brake fluid through the cylinder before installing it in the vehicle. This procedure ensures that the master cylinder functions properly by eliminating air pockets that can cause spongy brakes and reduces the risk of brake failure. Bench bleeding is performed using specialized tools and takes place outside the vehicle, providing a controlled environment to thoroughly purge trapped air.

Understanding On-Car Bleeding for Master Cylinders

On-car bleeding of master cylinders involves removing air directly from the hydraulic system while the master cylinder remains installed, ensuring more effective elimination of trapped air in brake lines. This method allows real-time assessment of brake fluid flow and pressure under actual operating conditions, improving brake responsiveness and safety. Compared to bench bleeding, on-car bleeding addresses issues caused by the entire brake system's configuration, leading to a more thorough and reliable brake system repair.

Key Differences: Bench Bleeding vs. On-Car Bleeding

Bench bleeding a master cylinder involves removing it from the vehicle and using a specialized kit to expel air and old fluid before installation, ensuring proper internal sealing and smooth pedal feel. On-car bleeding is performed with the master cylinder installed, flushing the entire brake system by pumping brake fluid through the lines to remove air bubbles and contaminants from the calipers or wheel cylinders. Bench bleeding focuses on preparing the master cylinder itself, while on-car bleeding addresses the entire brake hydraulic system for optimal braking performance.

Tools Required for Bench Bleeding Master Cylinders

Bench bleeding master cylinders requires a specialized bench bleeding kit, including a working fluid reservoir, clear tubing, and a stable workbench to simulate the braking system environment. Tools like a manual brake fluid bleeder pump, wrench set for disassembly, and a clean catch container are essential to properly remove air from the master cylinder before installation. In contrast, on-car bleeding typically uses standard brake bleeder tools and does not require the dedicated setup needed for bench bleeding.

Step-by-Step Guide: How to Bench Bleed a Master Cylinder

Bench bleeding a master cylinder involves securing the cylinder in a vise, filling it with brake fluid, and using bleeding tubes submerged in the fluid to pump the piston until no air bubbles appear. This step-by-step process ensures the removal of trapped air within the master cylinder before installation, improving brake system efficiency. In contrast, on-car bleeding addresses air in the entire brake system after installation but does not replace the crucial initial bench bleeding step.

Step-by-Step Process: On-Car Bleeding Explained

On-car bleeding involves installing the master cylinder in the vehicle before bleeding, ensuring the brake system remains sealed and preventing air entry. The step-by-step process includes topping off the brake fluid reservoir, loosening the bleeder valves at each wheel, pumping the brake pedal to expel air through the open valves, and tightening them sequentially while maintaining fluid levels. This method maintains the hydraulic integrity and is essential for achieving precise brake pedal feel and system performance.

Common Issues and Troubleshooting in Both Methods

Bench bleeding a master cylinder often reveals air bubbles trapped inside, causing spongy brake pedals and reduced braking efficiency, which can be resolved by careful piston actuation and fluid refilling. On-car bleeding frequently faces challenges such as improper brake line pressurization and the presence of contaminated or old brake fluid, leading to inconsistent hydraulic pressure and brake drag. Troubleshooting these issues involves systematic fluid purging, verifying vacuum or pressure bleeder function, and inspecting for leaks or damaged seals in both methods.

Pros and Cons: Bench Bleeding vs. On-Car Bleeding

Bench bleeding a master cylinder ensures thorough removal of trapped air and contaminants before installation, improving brake system performance and reducing the risk of spongy brakes. On-car bleeding allows for real-time air expulsion from the entire hydraulic system under actual operating conditions, simplifying the process and avoiding potential installation errors. Bench bleeding offers precise control and cleanliness, while on-car bleeding provides convenience and system-wide effectiveness, making the choice dependent on repair needs and equipment availability.

Best Practices for Effective Master Cylinder Bleeding

Bench bleeding the master cylinder ensures removal of trapped air by circulating brake fluid through the ports before installation, providing a fully primed system and reducing the risk of spongy brakes. On-car bleeding complements this process by expelling air from the entire brake circuit under real operating conditions, ensuring consistent hydraulic pressure and brake responsiveness. Combining bench bleeding with systematic on-car bleeding using proper tools and sequential bleeding order optimizes brake system performance and safety.

Bench bleeding master cylinder vs On-car bleeding Infographic

cardiffo.com

cardiffo.com