The H-pattern shifter provides a traditional manual shifting experience with a stable gate layout, making it intuitive for everyday driving and classic car enthusiasts. In contrast, the sequential shifter offers faster, more precise gear changes through a linear motion, which is favored in racing and performance applications. Choosing between them depends on whether smooth, familiar shifting or rapid, tactile engagement is the priority for the driver.

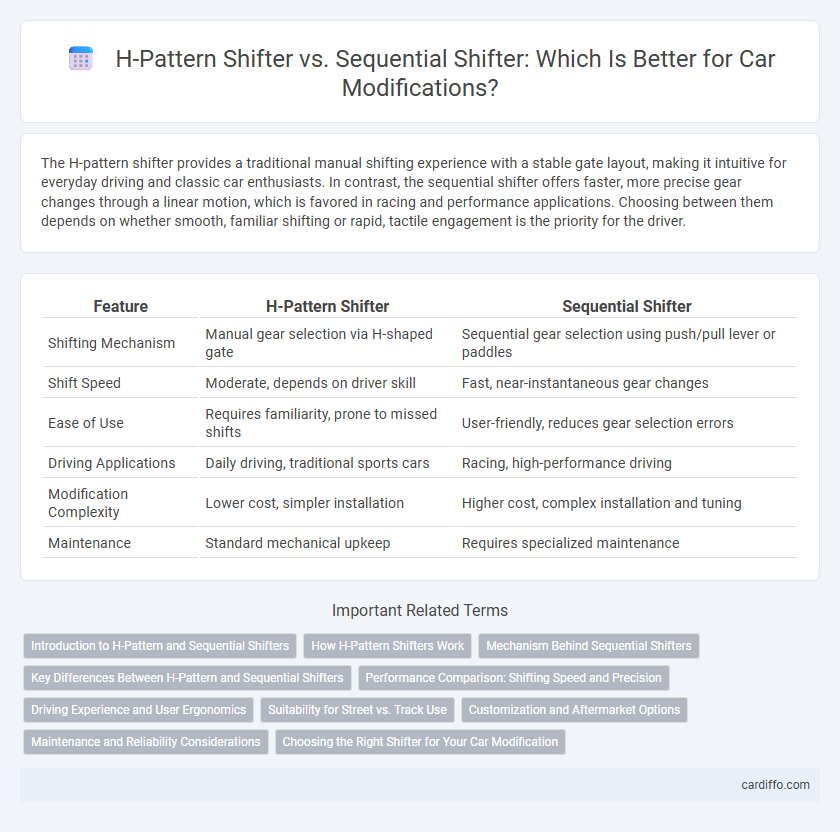

Table of Comparison

| Feature | H-Pattern Shifter | Sequential Shifter |

|---|---|---|

| Shifting Mechanism | Manual gear selection via H-shaped gate | Sequential gear selection using push/pull lever or paddles |

| Shift Speed | Moderate, depends on driver skill | Fast, near-instantaneous gear changes |

| Ease of Use | Requires familiarity, prone to missed shifts | User-friendly, reduces gear selection errors |

| Driving Applications | Daily driving, traditional sports cars | Racing, high-performance driving |

| Modification Complexity | Lower cost, simpler installation | Higher cost, complex installation and tuning |

| Maintenance | Standard mechanical upkeep | Requires specialized maintenance |

Introduction to H-Pattern and Sequential Shifters

H-pattern shifters feature a traditional gear layout arranged in an H-shaped pattern, providing tactile feedback and a distinct engagement for each gear position, commonly favored in manual transmission vehicles. Sequential shifters enable rapid gear changes by moving the shifter forward or backward through gears in order, without the need to navigate an H-pattern, frequently used in racing and high-performance cars. The fundamental difference lies in the precision and speed of shifting, where H-pattern shifters offer familiar control while sequential shifters prioritize swift gear selection.

How H-Pattern Shifters Work

H-pattern shifters operate through a traditional gate mechanism where the driver manually moves the gear lever along an H-shaped path to select gears, providing tactile feedback and precise control over gear changes. This system uses linkages connected to the transmission to physically engage gears, allowing for direct mechanical input without electronic intervention. The H-pattern design emphasizes driver engagement by requiring deliberate shifting motions, which contrasts with the automated nature of sequential shifters.

Mechanism Behind Sequential Shifters

Sequential shifters utilize a ratchet and pawl mechanism that engages gears in a fixed order, allowing the driver to shift up or down one gear at a time with precise control. This mechanism reduces the risk of missed shifts compared to the traditional H-pattern shifter, which requires manual navigation through an H-shaped gate. The design of sequential shifters enables faster gear changes and enhanced performance, particularly in motorsport applications.

Key Differences Between H-Pattern and Sequential Shifters

H-pattern shifters feature a traditional gated layout allowing direct access to each gear, offering a more intuitive and tactile driving experience favored for street driving and classic cars. Sequential shifters, common in racing and high-performance vehicles, enable gear changes in a linear order, resulting in faster, more precise shifts without the risk of skipping gears. The key differences include shifting mechanics, gear accessibility, and usage scenarios where H-pattern prioritizes driver engagement and sequential emphasizes performance efficiency.

Performance Comparison: Shifting Speed and Precision

An H-pattern shifter offers a tactile, intuitive driving experience with moderate shifting speed, relying on mechanical linkage for precise gear engagement but often slower than sequential systems. Sequential shifters enable faster, more precise gear changes by moving through gears in order, minimizing driver error and reducing shift times significantly, ideal for high-performance racing scenarios. The choice impacts overall vehicle control and lap times, with sequential shifters favored for performance-focused modifications due to superior speed and accuracy.

Driving Experience and User Ergonomics

H-pattern shifters offer a more traditional and engaging driving experience by requiring precise manual gear selection, enhancing driver control and connection to the vehicle. Sequential shifters simplify gear changes through a linear movement, improving ergonomics by allowing quicker, more intuitive shifts, especially in high-performance driving conditions. User ergonomics benefit from sequential shifters due to reduced hand movement and faster gear transitions, while H-pattern shifters prioritize tactile feedback and driver involvement.

Suitability for Street vs. Track Use

H-pattern shifters offer a more traditional, tactile feel preferred for street driving due to their intuitive gear layout and ease of use in traffic conditions. Sequential shifters provide faster, more precise gear changes ideal for track use where speed and shift accuracy impact performance significantly. Street drivers benefit from the familiar H-pattern, while racers prioritize the efficiency of sequential shifting for competitive environments.

Customization and Aftermarket Options

The H-pattern shifter offers extensive customization possibilities with various shift knob styles, materials, and linkage upgrades widely available in the aftermarket, catering to enthusiasts seeking a personalized driving experience. Sequential shifters, while more limited in traditional aftermarket accessories, provide electronic or hydraulic components that can be upgraded for improved shift speed and precision, appealing to performance-focused modifications. Both shifter types support tailored setups, but H-pattern systems dominate in aesthetic and tactile customization options.

Maintenance and Reliability Considerations

H-pattern shifters typically require less sophisticated electronics, making maintenance straightforward and often more cost-effective due to fewer components prone to failure. Sequential shifters, while offering faster gear changes and precision, involve complex electronic systems that demand specialized diagnostics and can increase maintenance frequency. Reliability in H-pattern systems benefits from mechanical simplicity, whereas sequential shifters may face higher risks of electronic malfunctions affecting overall durability.

Choosing the Right Shifter for Your Car Modification

Choosing the right shifter for your car modification depends on your driving style and performance goals. An H-pattern shifter offers traditional manual control suitable for daily driving and classic feel, while a sequential shifter provides faster, more precise gear changes favored in racing and high-performance applications. Evaluating factors like installation compatibility, budget, and intended use ensures optimal shift performance and enhances driving experience.

H-pattern shifter vs Sequential shifter Infographic

cardiffo.com

cardiffo.com