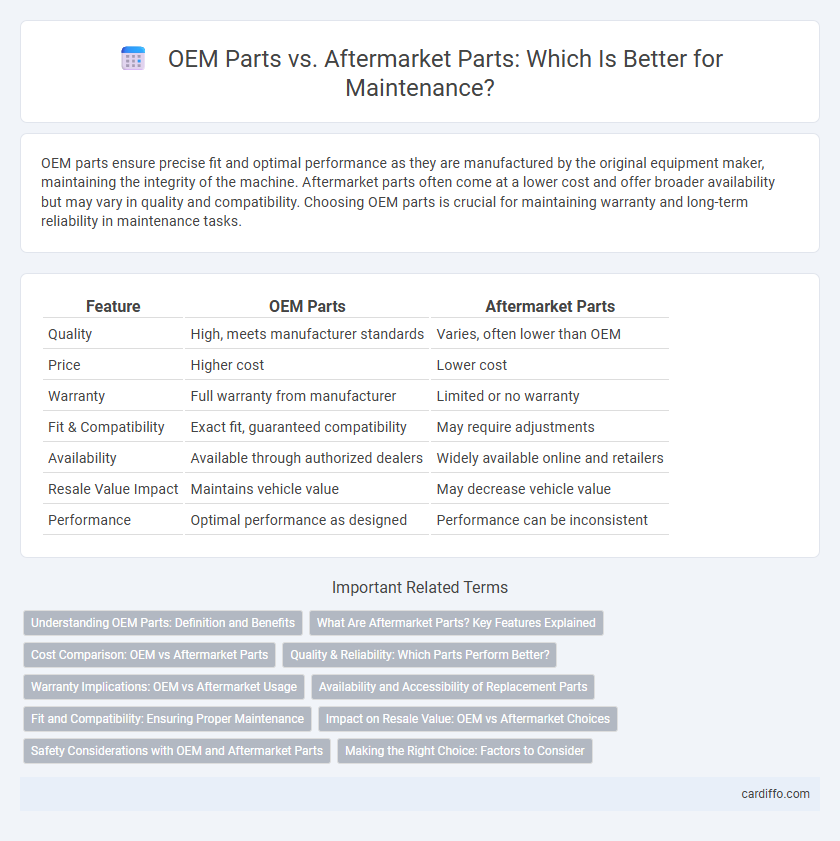

OEM parts ensure precise fit and optimal performance as they are manufactured by the original equipment maker, maintaining the integrity of the machine. Aftermarket parts often come at a lower cost and offer broader availability but may vary in quality and compatibility. Choosing OEM parts is crucial for maintaining warranty and long-term reliability in maintenance tasks.

Table of Comparison

| Feature | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality | High, meets manufacturer standards | Varies, often lower than OEM |

| Price | Higher cost | Lower cost |

| Warranty | Full warranty from manufacturer | Limited or no warranty |

| Fit & Compatibility | Exact fit, guaranteed compatibility | May require adjustments |

| Availability | Available through authorized dealers | Widely available online and retailers |

| Resale Value Impact | Maintains vehicle value | May decrease vehicle value |

| Performance | Optimal performance as designed | Performance can be inconsistent |

Understanding OEM Parts: Definition and Benefits

OEM parts are components manufactured by the original equipment manufacturer, ensuring exact fit and compatibility with the vehicle or machinery. These parts provide higher reliability and maintain the integrity of the equipment by meeting strict quality standards. Using OEM parts reduces the risk of premature failure and supports warranty compliance, enhancing long-term performance and safety.

What Are Aftermarket Parts? Key Features Explained

Aftermarket parts are components manufactured by companies other than the original equipment manufacturer (OEM). These parts often offer cost-effective alternatives with a wide range of options, including enhancements or modifications not found in OEM parts. Key features include compatibility with various vehicle models, varying quality levels, and availability for older or discontinued models.

Cost Comparison: OEM vs Aftermarket Parts

OEM parts typically cost 20-50% more than aftermarket parts due to brand certification, exact fit, and manufacturer warranties. Aftermarket parts offer a cost-effective solution, often priced 30-70% lower, but quality and compatibility can vary significantly. Maintenance budgets can benefit from aftermarket options if parts are chosen carefully to ensure durability and performance comparable to OEM standards.

Quality & Reliability: Which Parts Perform Better?

OEM parts are designed and manufactured by the original equipment manufacturer to meet exact specifications, ensuring optimal performance and compatibility. Aftermarket parts can vary significantly in quality, with some offering comparable reliability at lower costs while others may lead to reduced durability or fit issues. Studies show that OEM parts generally provide longer-lasting performance and better warranty coverage, making them preferable for maintaining vehicle integrity over time.

Warranty Implications: OEM vs Aftermarket Usage

Using OEM parts ensures full warranty compliance and preserves manufacturer coverage, as these components meet exact specifications and quality standards. Aftermarket parts may void warranties if they cause damage or do not adhere to original equipment requirements, leading to potential repair costs and denied claims. Maintenance professionals should verify warranty terms before opting for aftermarket components to avoid unexpected liabilities.

Availability and Accessibility of Replacement Parts

OEM parts guarantee precise compatibility and are widely available through authorized dealers, ensuring reliable access for planned maintenance. Aftermarket parts offer greater accessibility with varied suppliers and often faster delivery times, benefiting urgent repair needs. Availability of OEM parts might be limited for older models, whereas aftermarket options provide flexible alternatives to maintain equipment uptime.

Fit and Compatibility: Ensuring Proper Maintenance

OEM parts are engineered by the original equipment manufacturer to match exact specifications, guaranteeing superior fit and seamless compatibility with existing systems. Aftermarket parts vary in quality and dimensions, which can lead to improper installation or accelerated wear, compromising maintenance efforts. Choosing OEM components ensures precision, reliability, and enhanced longevity in equipment performance.

Impact on Resale Value: OEM vs Aftermarket Choices

OEM parts generally maintain higher resale value due to their guaranteed compatibility and warranty support, reflecting original manufacturer standards. Aftermarket parts may reduce resale value if buyers perceive them as lower quality or incompatible, despite offering cost savings. Choosing OEM parts ensures consistent performance and buyer confidence, which can enhance overall asset value during resale.

Safety Considerations with OEM and Aftermarket Parts

OEM parts are designed and tested to meet the original equipment manufacturer's safety standards, ensuring optimal compatibility and reliability in maintenance procedures. Aftermarket parts vary widely in quality and may lack thorough safety certifications, potentially compromising the structural integrity and performance of critical systems. Prioritizing OEM parts in safety-sensitive applications reduces the risk of malfunctions and enhances overall equipment longevity.

Making the Right Choice: Factors to Consider

Choosing between OEM parts and aftermarket parts involves evaluating factors such as quality, compatibility, warranty coverage, and cost-effectiveness. OEM parts offer precise fit and reliability, often backed by manufacturer warranties, while aftermarket parts provide more affordable options but can vary in quality and performance. Assessing vehicle requirements, maintenance schedules, and long-term value helps ensure the best decision for optimal maintenance outcomes.

OEM Parts vs Aftermarket Parts Infographic

cardiffo.com

cardiffo.com