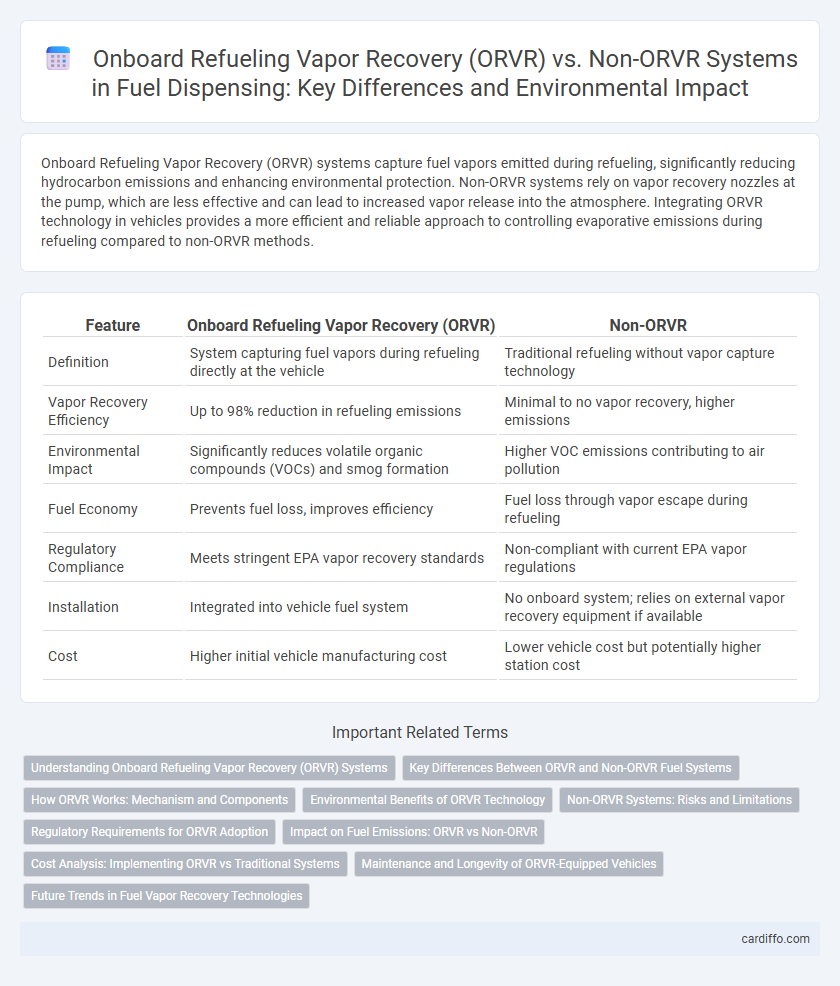

Onboard Refueling Vapor Recovery (ORVR) systems capture fuel vapors emitted during refueling, significantly reducing hydrocarbon emissions and enhancing environmental protection. Non-ORVR systems rely on vapor recovery nozzles at the pump, which are less effective and can lead to increased vapor release into the atmosphere. Integrating ORVR technology in vehicles provides a more efficient and reliable approach to controlling evaporative emissions during refueling compared to non-ORVR methods.

Table of Comparison

| Feature | Onboard Refueling Vapor Recovery (ORVR) | Non-ORVR |

|---|---|---|

| Definition | System capturing fuel vapors during refueling directly at the vehicle | Traditional refueling without vapor capture technology |

| Vapor Recovery Efficiency | Up to 98% reduction in refueling emissions | Minimal to no vapor recovery, higher emissions |

| Environmental Impact | Significantly reduces volatile organic compounds (VOCs) and smog formation | Higher VOC emissions contributing to air pollution |

| Fuel Economy | Prevents fuel loss, improves efficiency | Fuel loss through vapor escape during refueling |

| Regulatory Compliance | Meets stringent EPA vapor recovery standards | Non-compliant with current EPA vapor regulations |

| Installation | Integrated into vehicle fuel system | No onboard system; relies on external vapor recovery equipment if available |

| Cost | Higher initial vehicle manufacturing cost | Lower vehicle cost but potentially higher station cost |

Understanding Onboard Refueling Vapor Recovery (ORVR) Systems

Onboard Refueling Vapor Recovery (ORVR) systems capture fuel vapors released during vehicle refueling, significantly reducing evaporative emissions and improving air quality. These systems utilize a vapor canister and a sealed refueling nozzle interface to direct vapors into the vehicle's onboard storage, preventing them from escaping into the atmosphere. Compared to Non-ORVR systems, which rely on station-based vapor recovery, ORVR technology offers enhanced efficiency and compliance with stringent environmental regulations.

Key Differences Between ORVR and Non-ORVR Fuel Systems

Onboard Refueling Vapor Recovery (ORVR) systems capture fuel vapors during refueling, preventing their release into the atmosphere, unlike Non-ORVR systems that vent vapors directly. ORVR utilizes a carbon canister to absorb vapors, enhancing environmental protection and reducing evaporative emissions. In contrast, Non-ORVR systems rely on underground vapor recovery methods, which are less effective and contribute to higher volatile organic compound (VOC) emissions.

How ORVR Works: Mechanism and Components

Onboard Refueling Vapor Recovery (ORVR) systems capture fuel vapors released during refueling by using a sealed vapor recovery canister connected to the vehicle's fuel tank, preventing hydrocarbon emissions from escaping into the atmosphere. The mechanism involves routing vapor through a one-way valve into activated carbon canisters where hydrocarbons are absorbed until the engine burns them off during normal operation. Key components include the vapor containment valve, carbon canister, and purge valve, which work together to ensure efficient vapor capture and release, enhancing environmental compliance and reducing air pollution compared to Non-ORVR systems.

Environmental Benefits of ORVR Technology

Onboard Refueling Vapor Recovery (ORVR) systems significantly reduce hydrocarbon emissions by capturing fuel vapors during vehicle refueling, preventing their release into the atmosphere. Compared to Non-ORVR systems, ORVR technology achieves up to 98% efficiency in vapor recovery, substantially lowering smog-forming pollutants and improving air quality. This reduction in evaporative emissions aligns with regulatory standards targeting environmental protection and climate change mitigation.

Non-ORVR Systems: Risks and Limitations

Non-ORVR systems lack the advanced emissions control found in Onboard Refueling Vapor Recovery, leading to higher hydrocarbon vapor releases during refueling. These systems depend on stationary Stage II vapor recovery at fueling stations, which can be inconsistent and less effective, increasing environmental pollution risks. Non-ORVR vehicles also face elevated exposure to volatile organic compounds (VOCs), posing health hazards to users and contributing to costly regulatory non-compliance.

Regulatory Requirements for ORVR Adoption

Onboard Refueling Vapor Recovery (ORVR) systems are mandated by the Environmental Protection Agency (EPA) to reduce volatile organic compound (VOC) emissions during refueling, significantly curbing air pollution from fuel vapors. Non-ORVR systems lack this integrated vapor recovery, leading to higher emissions and failing to meet stringent regulatory standards established under the Clean Air Act. Compliance deadlines for ORVR adoption vary by vehicle model year and type, with regulatory frameworks ensuring phased implementation to achieve nationwide vapor recovery targets.

Impact on Fuel Emissions: ORVR vs Non-ORVR

Onboard Refueling Vapor Recovery (ORVR) systems significantly reduce fuel emissions by capturing and recycling vapors released during refueling, preventing volatile organic compounds (VOCs) from escaping into the atmosphere. Non-ORVR systems lack this containment, resulting in higher emissions of harmful pollutants such as benzene and other hydrocarbons. Studies show ORVR implementation can decrease hydrocarbon emissions from refueling by up to 90%, contributing markedly to improved air quality and reduced health risks.

Cost Analysis: Implementing ORVR vs Traditional Systems

Onboard Refueling Vapor Recovery (ORVR) systems reduce emissions by capturing fuel vapors during refueling, leading to potential long-term cost savings through decreased regulatory fines and improved environmental compliance. While implementing ORVR requires higher initial capital investment compared to traditional non-ORVR systems, the reduction in fuel loss and lower maintenance costs contribute to overall economic benefits. Traditional systems may have lower upfront costs but often incur higher expenses related to vapor emissions control and environmental penalties over time.

Maintenance and Longevity of ORVR-Equipped Vehicles

Onboard Refueling Vapor Recovery (ORVR) systems significantly reduce evaporative emissions during refueling by capturing fuel vapors internally, which decreases the risk of vapor leakage and contamination compared to Non-ORVR systems. Vehicles equipped with ORVR require less frequent maintenance of vapor recovery components, such as carbon canisters, due to the closed-loop design that minimizes particle buildup and system wear. Enhanced durability of ORVR components contributes to extended vehicle emission system longevity and improved compliance with stringent environmental regulations.

Future Trends in Fuel Vapor Recovery Technologies

Onboard Refueling Vapor Recovery (ORVR) systems are increasingly integrated into modern vehicles to capture fuel vapors during refueling, significantly reducing hydrocarbon emissions compared to Non-ORVR systems. Future trends emphasize advanced materials and sensor technologies to enhance vapor recovery efficiency, coupled with the adoption of IoT-enabled monitoring systems for real-time emission control. Emerging regulatory frameworks and growing environmental concerns drive innovation towards zero-emission vapor recovery solutions and seamless integration with electric and hydrogen fuel technologies.

Onboard Refueling Vapor Recovery vs Non-ORVR Infographic

cardiffo.com

cardiffo.com