Carburetor tuning involves adjusting mechanical components to optimize the air-fuel mixture for engine performance, while fuel injection mapping relies on electronic control units to precisely regulate fuel delivery based on real-time sensor data. Fuel injection mapping offers improved fuel efficiency, better throttle response, and reduced emissions compared to the more traditional and manual process of carburetor tuning. Modern engines benefit from fuel injection mapping due to its adaptability to varying conditions and enhanced engine management capabilities.

Table of Comparison

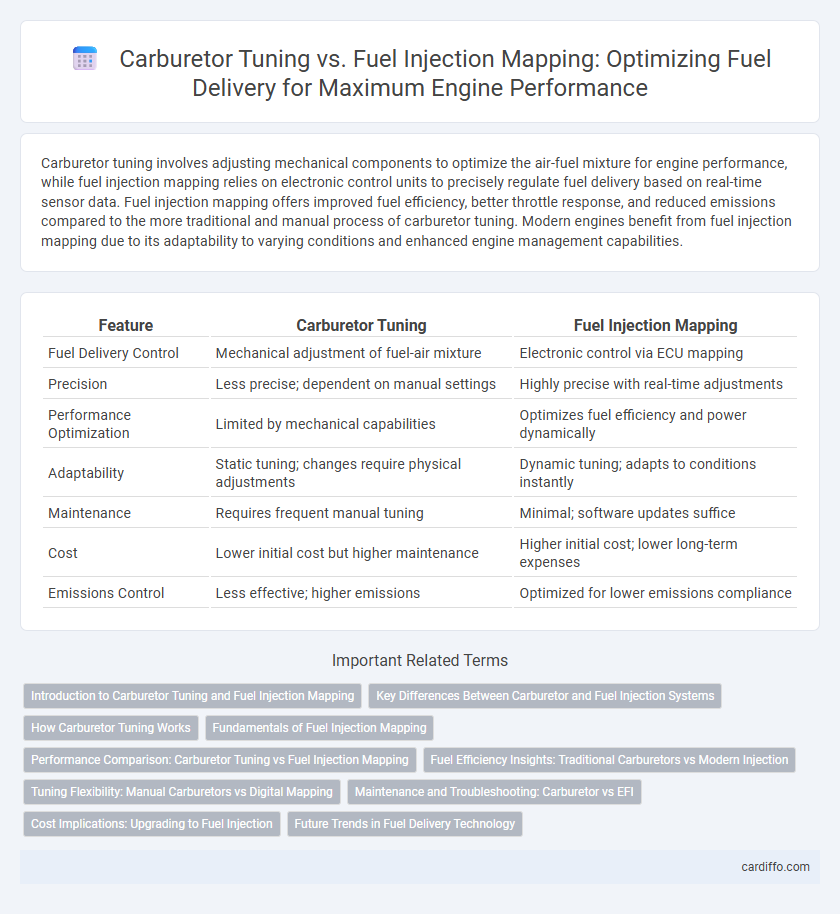

| Feature | Carburetor Tuning | Fuel Injection Mapping |

|---|---|---|

| Fuel Delivery Control | Mechanical adjustment of fuel-air mixture | Electronic control via ECU mapping |

| Precision | Less precise; dependent on manual settings | Highly precise with real-time adjustments |

| Performance Optimization | Limited by mechanical capabilities | Optimizes fuel efficiency and power dynamically |

| Adaptability | Static tuning; changes require physical adjustments | Dynamic tuning; adapts to conditions instantly |

| Maintenance | Requires frequent manual tuning | Minimal; software updates suffice |

| Cost | Lower initial cost but higher maintenance | Higher initial cost; lower long-term expenses |

| Emissions Control | Less effective; higher emissions | Optimized for lower emissions compliance |

Introduction to Carburetor Tuning and Fuel Injection Mapping

Carburetor tuning involves adjusting the air-fuel mixture mechanically to optimize engine performance, primarily used in older vehicles with simpler engine designs. Fuel injection mapping, by contrast, uses electronic controls to precisely manage fuel delivery based on real-time engine data, enhancing efficiency and emissions control. Understanding the differences in these systems is crucial for selecting the appropriate tuning method for specific engine types and performance goals.

Key Differences Between Carburetor and Fuel Injection Systems

Carburetor tuning adjusts the air-fuel mixture mechanically through jets and needles, relying on vacuum and pressure changes, while fuel injection mapping uses electronic control units (ECUs) to precisely regulate fuel delivery via sensors and injectors. Carburetors lack real-time adaptability, making them less efficient and less responsive to varying engine conditions compared to fuel injection systems that optimize performance and emissions dynamically. Fuel injection systems provide improved fuel atomization, better fuel economy, and lower emissions due to precise electronic control, which carburetors cannot match.

How Carburetor Tuning Works

Carburetor tuning adjusts the air-fuel mixture by modifying the throttle, jets, and needle positions to achieve optimal combustion efficiency. This mechanical process controls fuel flow by regulating pressure differences and airflow through the carburetor venturi, ensuring the engine receives the correct fuel ratio for various operating conditions. Precise carburetor tuning improves engine performance, fuel economy, and reduces emissions by optimizing the mixture for idle, acceleration, and cruising states.

Fundamentals of Fuel Injection Mapping

Fuel injection mapping fundamentally involves calibrating the engine control unit (ECU) to precisely regulate the air-fuel mixture for optimal combustion efficiency and performance. Unlike carburetor tuning, which relies on mechanical adjustments to control fuel flow, fuel injection mapping uses sensors and software to adjust injection timing, duration, and fuel quantity dynamically based on real-time engine parameters. This electronic control enhances fuel economy, reduces emissions, and improves throttle response by delivering the exact amount of fuel required under varying operating conditions.

Performance Comparison: Carburetor Tuning vs Fuel Injection Mapping

Carburetor tuning offers mechanical simplicity and adjustability ideal for classic engines, providing a hands-on approach to air-fuel mixture optimization. Fuel injection mapping delivers precise control over fuel delivery using electronic sensors and computer algorithms, enhancing fuel efficiency, throttle response, and emissions performance. Modern performance gains typically favor fuel injection mapping due to its adaptability and accuracy under varying operating conditions.

Fuel Efficiency Insights: Traditional Carburetors vs Modern Injection

Carburetor tuning relies on mechanical adjustments to balance air-fuel mixture, often resulting in less precise fuel delivery and lower efficiency compared to modern fuel injection mapping. Fuel injection systems utilize electronic control units (ECUs) to optimize fuel spray patterns and timing, significantly improving combustion efficiency and reducing fuel consumption. Data shows fuel injection can enhance fuel economy by up to 15-20%, especially in varying load and speed conditions where carburetors struggle to adapt.

Tuning Flexibility: Manual Carburetors vs Digital Mapping

Manual carburetors offer direct mechanical adjustments, enabling quick and intuitive tuning for varying fuel-air mixtures in different driving conditions. Digital fuel injection mapping provides precise, computer-controlled optimization of fuel delivery, allowing for dynamic adjustments based on real-time engine data and environmental factors. While carburetors excel in simplicity and ease of manual tuning, fuel injection systems deliver unparalleled accuracy and adaptability through advanced electronic control units (ECUs).

Maintenance and Troubleshooting: Carburetor vs EFI

Carburetor tuning requires frequent manual adjustments to maintain optimal air-fuel mixture, making maintenance labor-intensive and prone to inconsistencies. Fuel Injection Mapping offers precise electronic control of fuel delivery, reducing maintenance frequency and enabling diagnostic troubleshooting through onboard sensors and computer systems. EFI systems enhance reliability and performance by automatically correcting fuel ratios, while carburetors demand skilled mechanical intervention for troubleshooting fuel-related issues.

Cost Implications: Upgrading to Fuel Injection

Upgrading to fuel injection involves higher initial costs compared to carburetor tuning, primarily due to the price of fuel injectors, electronic control units, and installation labor. While carburetor tuning requires less investment, it often results in less precise fuel delivery and lower fuel efficiency. Fuel injection mapping enhances engine performance and fuel economy, which can offset upfront expenses over time through reduced fuel consumption and maintenance costs.

Future Trends in Fuel Delivery Technology

Future trends in fuel delivery technology emphasize advanced fuel injection mapping over traditional carburetor tuning due to precision control and improved fuel efficiency. Electronic fuel injection systems utilize real-time data analytics and adaptive algorithms to optimize combustion, reduce emissions, and enhance engine performance. Emerging innovations include machine learning integration and sensor fusion to enable predictive adjustments, signaling a shift toward smarter, more responsive fuel delivery solutions.

Carburetor Tuning vs Fuel Injection Mapping Infographic

cardiffo.com

cardiffo.com