Biodiesel is produced from renewable biological sources such as vegetable oils and animal fats, offering a lower carbon footprint and improved biodegradability compared to synthetic diesel. Synthetic diesel is created through chemical processes like Fischer-Tropsch synthesis, providing a cleaner burn and higher energy density but relying on fossil or alternative feedstocks. Both fuels serve as sustainable alternatives to conventional diesel, with biodiesel excelling in renewable content and synthetic diesel delivering superior engine performance and emissions control.

Table of Comparison

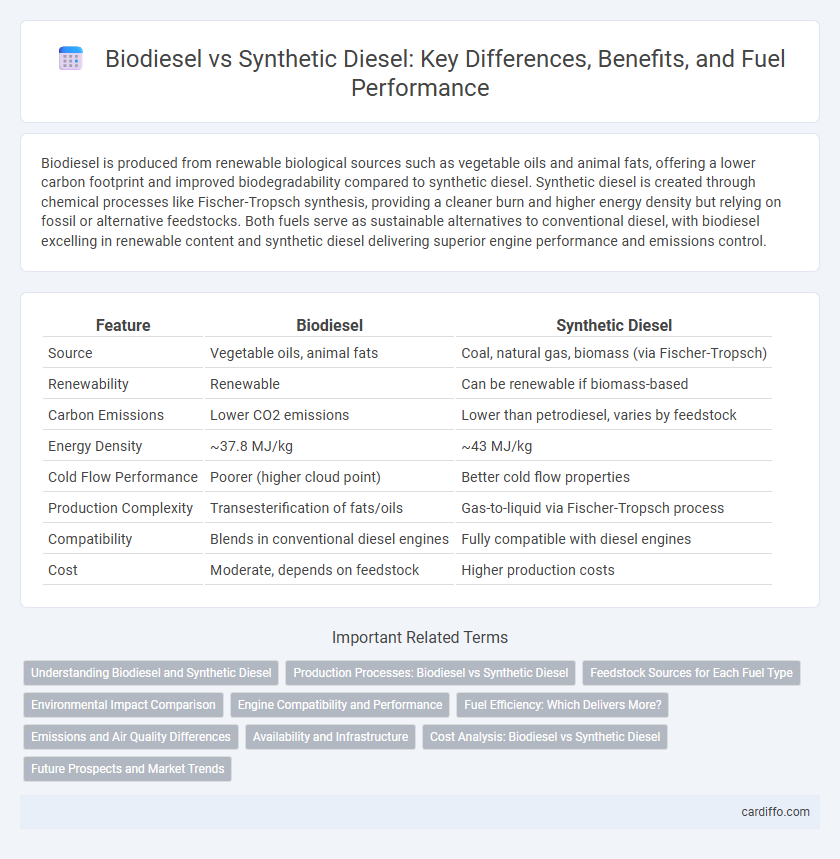

| Feature | Biodiesel | Synthetic Diesel |

|---|---|---|

| Source | Vegetable oils, animal fats | Coal, natural gas, biomass (via Fischer-Tropsch) |

| Renewability | Renewable | Can be renewable if biomass-based |

| Carbon Emissions | Lower CO2 emissions | Lower than petrodiesel, varies by feedstock |

| Energy Density | ~37.8 MJ/kg | ~43 MJ/kg |

| Cold Flow Performance | Poorer (higher cloud point) | Better cold flow properties |

| Production Complexity | Transesterification of fats/oils | Gas-to-liquid via Fischer-Tropsch process |

| Compatibility | Blends in conventional diesel engines | Fully compatible with diesel engines |

| Cost | Moderate, depends on feedstock | Higher production costs |

Understanding Biodiesel and Synthetic Diesel

Biodiesel, derived from renewable biological sources such as vegetable oils and animal fats, offers a sustainable alternative to petroleum diesel by reducing greenhouse gas emissions up to 78% over its lifecycle. Synthetic diesel, produced through Fischer-Tropsch synthesis or hydroprocessing of biomass, coal, or natural gas, provides a cleaner-burning fuel with higher purity and consistent quality, enhancing engine performance and reducing particulate matter emissions. Both fuels serve as crucial components in the transition to low-carbon transportation, yet biodiesel's biodegradability contrasts with synthetic diesel's superior cold-flow properties and energy density.

Production Processes: Biodiesel vs Synthetic Diesel

Biodiesel is produced through a transesterification process that converts vegetable oils or animal fats into fatty acid methyl esters (FAME), utilizing alcohol and a catalyst, while synthetic diesel is manufactured via Fischer-Tropsch synthesis, which converts carbon monoxide and hydrogen derived from natural gas or biomass into liquid hydrocarbons. Biodiesel production relies heavily on renewable feedstocks with lower energy input, whereas synthetic diesel involves complex gasification or reforming technologies demanding higher energy consumption but yielding a cleaner, sulfur-free fuel. The choice between these processes affects fuel properties, carbon footprint, and scalability for meeting diverse energy demands.

Feedstock Sources for Each Fuel Type

Biodiesel is primarily derived from renewable feedstocks such as vegetable oils, animal fats, and recycled cooking oils, making it a sustainable alternative to traditional diesel. Synthetic diesel, also known as Fischer-Tropsch diesel, is produced through gasification of coal, natural gas, or biomass, offering flexibility in feedstock utilization. The choice of feedstock directly impacts fuel properties, production costs, and environmental footprint.

Environmental Impact Comparison

Biodiesel produces significantly lower greenhouse gas emissions compared to synthetic diesel, cutting carbon dioxide output by up to 78% due to its renewable origins from vegetable oils and animal fats. Synthetic diesel, derived from natural gas or coal through the Fischer-Tropsch process, typically results in higher lifecycle emissions unless paired with carbon capture technology. The biodegradability and reduced toxicity of biodiesel also contribute to lower environmental risks in cases of spills or leaks, making it a more eco-friendly alternative to conventional synthetic diesel fuels.

Engine Compatibility and Performance

Biodiesel blends up to B20 are generally compatible with most diesel engines without modifications, offering improved lubricity and reduced emissions but may cause issues like filter clogging in older engines. Synthetic diesel, produced via Fischer-Tropsch synthesis, provides superior combustion quality, higher cetane numbers, and consistent engine performance with minimal deposit formation. Engine manufacturers often recommend synthetic diesel for enhanced durability and cold-weather operability, although cost and availability remain limiting factors.

Fuel Efficiency: Which Delivers More?

Biodiesel typically provides slightly lower fuel efficiency compared to synthetic diesel due to its higher viscosity and energy content, resulting in reduced miles per gallon. Synthetic diesel, produced through processes like Fischer-Tropsch synthesis, offers superior combustion properties and energy density, maximizing fuel efficiency in engines. Studies indicate synthetic diesel can improve fuel economy by up to 10% when compared to biodiesel blends under similar operational conditions.

Emissions and Air Quality Differences

Biodiesel significantly reduces particulate matter (PM), carbon monoxide (CO), and unburned hydrocarbons (UHC) emissions compared to synthetic diesel, contributing to improved air quality and lower smog formation. Synthetic diesel, derived from processes like Fischer-Tropsch, offers near-zero sulfur content and lower nitrogen oxides (NOx) emissions, enhancing combustion efficiency and reducing acid rain potential. Both fuels contribute to decreased greenhouse gas emissions, but biodiesel's renewable origin further supports carbon cycle balance and sustainability goals.

Availability and Infrastructure

Biodiesel benefits from widespread availability due to its compatibility with existing diesel infrastructure and distribution networks, facilitating easier adoption across fuel stations globally. Synthetic diesel faces limited availability, as its production relies on advanced technologies like Fischer-Tropsch synthesis, resulting in fewer dedicated refineries and distribution channels. Infrastructure for biodiesel is more developed, while synthetic diesel requires significant investment to expand fueling facilities and storage systems.

Cost Analysis: Biodiesel vs Synthetic Diesel

Biodiesel often incurs lower production costs due to the use of renewable feedstocks such as vegetable oils and animal fats, while synthetic diesel requires energy-intensive processes like Fischer-Tropsch synthesis, increasing its overall expense. Price volatility in raw material markets heavily impacts biodiesel costs, whereas synthetic diesel benefits from more stable pricing tied to natural gas or coal feedstocks. Lifecycle cost analysis reveals biodiesel's advantage in sustainability incentives and reduced carbon taxes, offsetting synthetic diesel's potentially higher initial investment and infrastructure expenses.

Future Prospects and Market Trends

Biodiesel demand is expected to grow steadily due to increasing government mandates and the push for renewable energy sources in transportation. Synthetic diesel, produced from natural gas or biomass through the Fischer-Tropsch process, offers higher energy density and lower emissions, making it attractive for heavy-duty and industrial applications. Emerging market trends indicate a rising preference for synthetic diesel in regions prioritizing advanced fuel technologies, while biodiesel remains dominant in areas with abundant feedstock and supportive regulatory frameworks.

biodiesel vs synthetic diesel Infographic

cardiffo.com

cardiffo.com