Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, enhancing fuel efficiency and power output compared to Port Fuel Injection (PFI), which sprays fuel into the intake manifold. GDI systems provide precise fuel metering and improved throttle response, resulting in lower emissions and better fuel economy. However, PFI engines tend to have cleaner intake valves and simpler maintenance due to less carbon buildup.

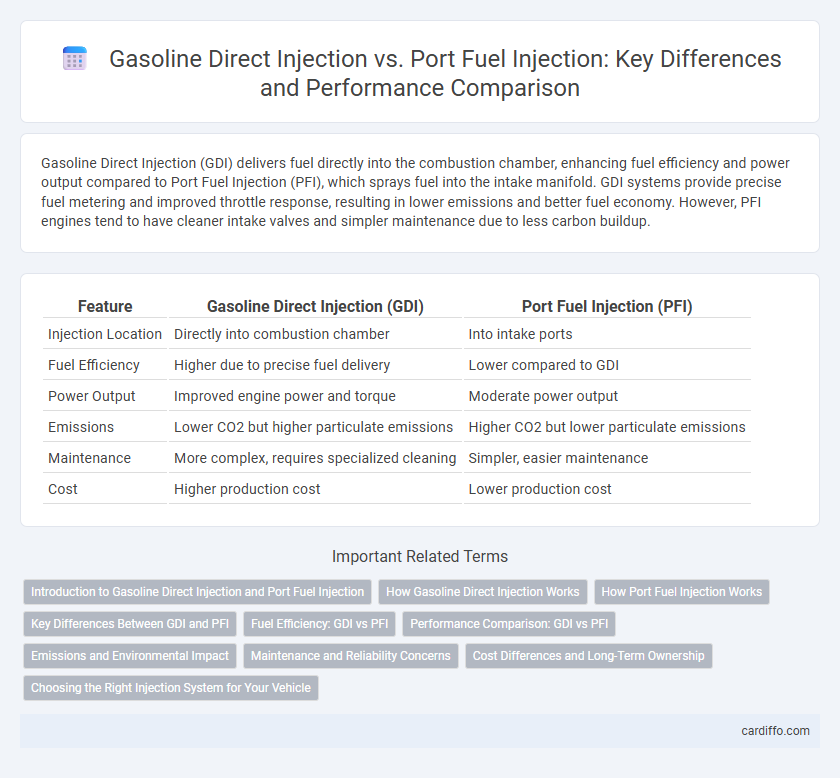

Table of Comparison

| Feature | Gasoline Direct Injection (GDI) | Port Fuel Injection (PFI) |

|---|---|---|

| Injection Location | Directly into combustion chamber | Into intake ports |

| Fuel Efficiency | Higher due to precise fuel delivery | Lower compared to GDI |

| Power Output | Improved engine power and torque | Moderate power output |

| Emissions | Lower CO2 but higher particulate emissions | Higher CO2 but lower particulate emissions |

| Maintenance | More complex, requires specialized cleaning | Simpler, easier maintenance |

| Cost | Higher production cost | Lower production cost |

Introduction to Gasoline Direct Injection and Port Fuel Injection

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, enhancing fuel atomization and combustion efficiency for improved power output and reduced emissions. Port Fuel Injection (PFI) sprays fuel into the intake ports, allowing it to mix with air before entering the combustion chamber, which promotes better air-fuel mixing and reduces carbon buildup on intake valves. GDI systems offer superior fuel economy and performance, while PFI systems provide lower manufacturing costs and simpler maintenance.

How Gasoline Direct Injection Works

Gasoline Direct Injection (GDI) injects fuel directly into the combustion chamber at high pressure, allowing for precise control over the fuel-air mixture and improved combustion efficiency. This method enhances power output, fuel economy, and reduces emissions by optimizing the timing and amount of fuel delivery during the intake and compression strokes. GDI systems use advanced injectors and electronic controls to achieve better atomization and distribution compared to Port Fuel Injection (PFI), which injects fuel into the intake manifold.

How Port Fuel Injection Works

Port Fuel Injection (PFI) delivers fuel directly into the intake ports, where it mixes with air before entering the combustion chamber. This method ensures precise fuel atomization and distribution, enhancing combustion efficiency and reducing emissions. PFI systems rely on electronic control units to time injection pulses, optimizing performance across different engine loads and speeds.

Key Differences Between GDI and PFI

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, enhancing fuel atomization and improving engine efficiency compared to Port Fuel Injection (PFI), which sprays fuel into the intake manifold. GDI systems offer better fuel economy and higher power output due to precise fuel control, while PFI engines typically produce fewer particulate emissions and are less prone to carbon buildup on intake valves. Maintenance complexity and emissions behavior differ significantly between GDI and PFI, impacting long-term engine performance and environmental compliance.

Fuel Efficiency: GDI vs PFI

Gasoline Direct Injection (GDI) engines deliver fuel directly into the combustion chamber, enhancing fuel atomization and combustion efficiency, which typically results in better fuel economy compared to Port Fuel Injection (PFI) systems that spray fuel into the intake manifold. GDI technology reduces fuel consumption by enabling precise control over the fuel-air mixture, especially under partial load conditions, making it highly effective for improving miles per gallon (MPG). However, PFI systems tend to have lower emissions of particulate matter, although fuel efficiency in GDI engines generally outperforms PFI in modern vehicles.

Performance Comparison: GDI vs PFI

Gasoline Direct Injection (GDI) systems deliver fuel directly into the combustion chamber, resulting in higher fuel atomization and improved combustion efficiency compared to Port Fuel Injection (PFI), which injects fuel into the intake manifold. GDI engines typically achieve better power output and torque due to precise fuel metering and optimized air-fuel mixture, enhancing throttle response and acceleration. However, PFI offers more consistent fuel-air mixing that can reduce particulate emissions, though it generally lags behind GDI in overall performance and fuel economy.

Emissions and Environmental Impact

Gasoline Direct Injection (GDI) engines produce higher levels of particulate matter compared to Port Fuel Injection (PFI) systems, leading to increased environmental concerns. GDI improves fuel efficiency and reduces CO2 emissions, but its elevated particulate emissions require advanced filtration systems to meet stringent environmental standards. PFI engines generally emit fewer particulates but have slightly higher CO2 emissions, presenting a trade-off between combustion efficiency and particulate output.

Maintenance and Reliability Concerns

Gasoline Direct Injection (GDI) engines often require more frequent maintenance due to carbon buildup on intake valves, which can lead to reduced performance and increased repair costs. Port Fuel Injection (PFI) systems, by spraying fuel into the intake ports, help cleanse valves naturally, resulting in fewer carbon deposit issues and generally higher reliability over time. While GDI offers better fuel efficiency and power, PFI engines typically benefit from lower maintenance demands and longer-term durability.

Cost Differences and Long-Term Ownership

Gasoline Direct Injection (GDI) systems often have higher initial manufacturing and repair costs compared to Port Fuel Injection (PFI) due to their advanced technology and precision components. Over the long term, GDI engines may incur increased maintenance expenses from carbon buildup on intake valves, whereas PFI engines typically experience lower maintenance costs. Fuel efficiency improvements with GDI can offset some expenses, but total ownership costs depend on driving habits and fuel quality.

Choosing the Right Injection System for Your Vehicle

Gasoline Direct Injection (GDI) offers improved fuel efficiency and power by delivering fuel directly into the combustion chamber, enhancing combustion precision and reducing emissions. Port Fuel Injection (PFI) injects fuel into the intake manifold, providing better fuel atomization and reliability, especially in older engines or those prone to carbon buildup. Selecting the right injection system depends on your vehicle's engine design, performance needs, and maintenance preferences, as GDI suits modern high-performance engines while PFI remains cost-effective and simpler to maintain.

Gasoline Direct Injection vs Port Fuel Injection Infographic

cardiffo.com

cardiffo.com