String alignment offers a cost-effective and simple method for aligning mechanical components using visual guides and tensioned strings, ideal for preliminary setups or tight budgets. Laser alignment provides superior precision and efficiency through advanced optics and digital feedback, making it preferred for critical applications requiring exact measurements and minimal downtime. Both techniques serve distinct operational needs, with laser alignment excelling in accuracy while string alignment remains valuable for quick, low-cost adjustments.

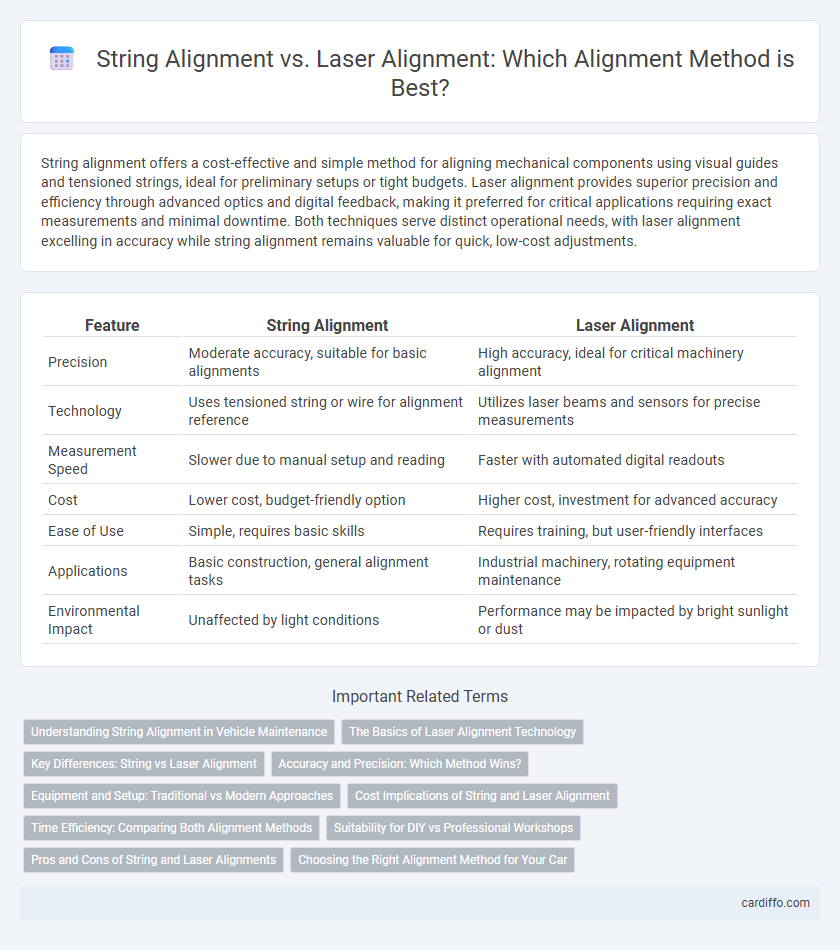

Table of Comparison

| Feature | String Alignment | Laser Alignment |

|---|---|---|

| Precision | Moderate accuracy, suitable for basic alignments | High accuracy, ideal for critical machinery alignment |

| Technology | Uses tensioned string or wire for alignment reference | Utilizes laser beams and sensors for precise measurements |

| Measurement Speed | Slower due to manual setup and reading | Faster with automated digital readouts |

| Cost | Lower cost, budget-friendly option | Higher cost, investment for advanced accuracy |

| Ease of Use | Simple, requires basic skills | Requires training, but user-friendly interfaces |

| Applications | Basic construction, general alignment tasks | Industrial machinery, rotating equipment maintenance |

| Environmental Impact | Unaffected by light conditions | Performance may be impacted by bright sunlight or dust |

Understanding String Alignment in Vehicle Maintenance

String alignment in vehicle maintenance involves using a taut string as a reference line to check the straightness and alignment of wheels, ensuring proper tire wear and handling performance. Unlike laser alignment, which uses precise beams and sensors for digital measurements, string alignment provides a cost-effective and straightforward method ideal for quick inspections and adjustments. This technique helps identify misalignment issues by visually comparing wheel positions against the string, promoting accurate steering and improved fuel efficiency.

The Basics of Laser Alignment Technology

Laser alignment technology utilizes coherent light beams to achieve precise positioning and calibration of machinery components, offering significantly higher accuracy compared to traditional string alignment methods. Unlike string alignment, which relies on manual tension and visual estimation, laser alignment systems provide real-time digital feedback and measurements, reducing human error and setup time. This technology is essential in industrial applications where exact alignment is critical for optimal machine performance and longevity.

Key Differences: String vs Laser Alignment

String alignment relies on physical strings or wires stretched between reference points to achieve straightness, making it cost-effective and simple but less precise. Laser alignment uses laser beams and sensors to measure distances and angles with high accuracy, offering quicker setups and the ability to detect minute misalignments. While string alignment suits basic tasks and larger tolerances, laser alignment is preferred for precision-critical applications requiring exact measurements and digital documentation.

Accuracy and Precision: Which Method Wins?

Laser alignment consistently outperforms string alignment in both accuracy and precision due to its ability to provide real-time, high-resolution measurements that minimize human error and environmental interference. String alignment, while simpler and cost-effective, often suffers from sag, vibration, and limited measurement granularity, leading to less reliable results. For critical industrial applications demanding exact positioning and minimal tolerance, laser alignment is the superior choice, delivering near-perfect alignment with repeatability and confidence.

Equipment and Setup: Traditional vs Modern Approaches

String alignment relies on simple, flexible string lines stretched between equipment points, requiring minimal setup and basic tools, making it accessible for traditional applications with limited resources. Laser alignment employs advanced laser beams and precise sensors, providing highly accurate measurements and faster setup, ideal for modern industrial environments demanding exact alignment and reduced downtime. Equipment for laser alignment often includes portable laser transmitters, receivers, and digital displays, contrasting with the rudimentary fittings and optical scopes used in string methods.

Cost Implications of String and Laser Alignment

String alignment offers a cost-effective solution with lower initial investment and minimal equipment requirements, making it ideal for businesses with budget constraints. Laser alignment, while more expensive upfront due to advanced technology and precision tools, reduces long-term costs by minimizing downtime and increasing alignment accuracy, which leads to extended machinery lifespan and reduced maintenance. Choosing between string and laser alignment depends on balancing immediate budget limits against potential savings from enhanced operational efficiency.

Time Efficiency: Comparing Both Alignment Methods

Laser alignment offers superior time efficiency compared to string alignment by providing rapid, precise measurements that reduce setup and adjustment time significantly. String alignment requires manual adjustments and more frequent checks, prolonging the alignment process especially in complex machinery. The high accuracy and automation of laser alignment minimize downtime and enhance overall productivity in industrial applications.

Suitability for DIY vs Professional Workshops

String alignment is highly suitable for DIY enthusiasts due to its simplicity, low cost, and minimal equipment requirements, making it ideal for basic alignment tasks at home. Laser alignment, preferred in professional workshops, offers superior precision and efficiency through advanced technology, essential for complex or high-stakes projects requiring exact measurements. Workshops equipped with laser alignment systems can achieve faster setup times and greater consistency compared to the manual approach of string alignment.

Pros and Cons of String and Laser Alignments

String alignment offers cost-effective and straightforward installation suitable for large-scale projects but lacks the precision needed for highly sensitive equipment. Laser alignment provides superior accuracy and real-time feedback, reducing downtime and maintenance costs, yet the higher initial investment and complexity may not justify its use in simpler applications. Selecting between string and laser alignment depends on balancing project scale, precision requirements, and budget constraints.

Choosing the Right Alignment Method for Your Car

String alignment offers a cost-effective and straightforward approach for basic wheel alignment, ideal for routine maintenance and simple adjustments. Laser alignment provides high precision and advanced diagnostic capabilities, making it the preferred choice for performance vehicles and detailed alignment tasks. Selecting the right method depends on your car's alignment needs, budget, and the precision required for optimal tire wear and handling.

String alignment vs Laser alignment Infographic

cardiffo.com

cardiffo.com