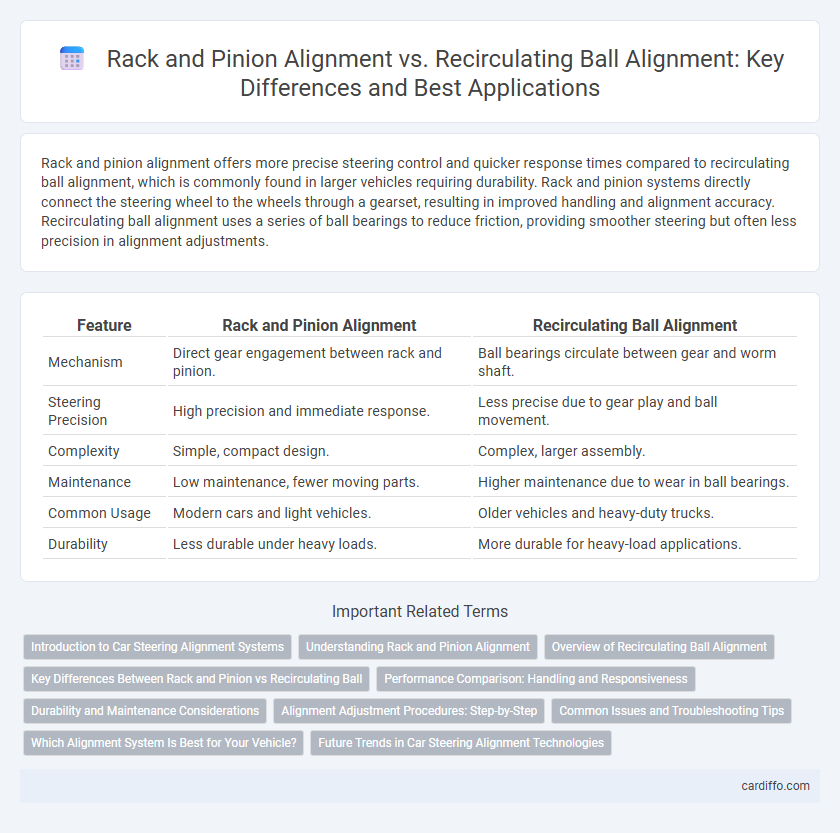

Rack and pinion alignment offers more precise steering control and quicker response times compared to recirculating ball alignment, which is commonly found in larger vehicles requiring durability. Rack and pinion systems directly connect the steering wheel to the wheels through a gearset, resulting in improved handling and alignment accuracy. Recirculating ball alignment uses a series of ball bearings to reduce friction, providing smoother steering but often less precision in alignment adjustments.

Table of Comparison

| Feature | Rack and Pinion Alignment | Recirculating Ball Alignment |

|---|---|---|

| Mechanism | Direct gear engagement between rack and pinion. | Ball bearings circulate between gear and worm shaft. |

| Steering Precision | High precision and immediate response. | Less precise due to gear play and ball movement. |

| Complexity | Simple, compact design. | Complex, larger assembly. |

| Maintenance | Low maintenance, fewer moving parts. | Higher maintenance due to wear in ball bearings. |

| Common Usage | Modern cars and light vehicles. | Older vehicles and heavy-duty trucks. |

| Durability | Less durable under heavy loads. | More durable for heavy-load applications. |

Introduction to Car Steering Alignment Systems

Rack and pinion alignment offers precise, responsive steering by directly connecting the steering wheel to the wheels through a simple gear mechanism, enhancing vehicle control and handling. Recirculating ball alignment utilizes a complex system with ball bearings circulating within the steering box, providing durability and smooth operation in heavy-duty vehicles but potentially less direct feedback. Understanding the differences in these steering alignment systems is crucial for optimizing vehicle performance and ensuring accurate steering response.

Understanding Rack and Pinion Alignment

Rack and pinion alignment involves ensuring the precise meshing of the toothed rack with the pinion gear to maintain accurate steering response and reduce wear. Proper alignment minimizes steering wheel play, enhances vehicle handling, and prevents premature component failure. Rack and pinion systems offer direct steering feedback compared to recirculating ball mechanisms, making alignment accuracy critical for optimal performance.

Overview of Recirculating Ball Alignment

Recirculating ball alignment involves a steering mechanism where a series of ball bearings circulate within a precision-machined channel to reduce friction between the steering shaft and the gear housing. This system provides smooth, durable steering performance ideal for heavy-duty vehicles and off-road applications, differing from rack and pinion alignment, which is typically preferred for lighter, more responsive steering. Proper recirculating ball alignment ensures minimal play in the steering wheel, enhances vehicle stability, and extends the lifespan of steering components under high-torque conditions.

Key Differences Between Rack and Pinion vs Recirculating Ball

Rack and pinion steering systems provide direct and responsive control by converting the rotational motion of the steering wheel into linear motion, favoring precision in vehicle alignment. Recirculating ball steering relies on a gearbox mechanism with ball bearings to reduce friction, resulting in smoother but less precise steering feedback. Key differences in alignment involve the complexity of adjustment and maintenance, as rack and pinion systems require more precise calibration for optimal performance, while recirculating ball systems allow for greater tolerance but may develop play over time.

Performance Comparison: Handling and Responsiveness

Rack and Pinion alignment offers superior handling and responsiveness due to its direct steering mechanism, providing precise control and quicker feedback from the road. Recirculating Ball alignment, while robust and durable, tends to deliver less precise steering with slower response times, making it less suitable for high-performance driving. The increased mechanical efficiency in rack and pinion systems enhances vehicle agility, especially in tight turns and rapid directional changes.

Durability and Maintenance Considerations

Rack and pinion alignment offers superior durability due to fewer moving parts and simpler mechanics, reducing wear and tear compared to recirculating ball systems. Maintenance is typically easier and less frequent for rack and pinion, involving minimal lubrication and straightforward adjustments. In contrast, recirculating ball alignment requires more regular maintenance and can suffer from quicker component degradation due to complex internal mechanisms and higher friction points.

Alignment Adjustment Procedures: Step-by-Step

Rack and pinion alignment adjustment involves precise calibration of the steering gear to ensure minimal play and accurate steering response, typically starting with loosening the mounting bolts, centering the steering wheel, and adjusting the pinion depth or lash according to manufacturer specifications. Recirculating ball alignment adjustment requires setting the correct preload on the sector shaft bearings and adjusting the worm gear mesh to eliminate excessive free play, often involving stepwise tightening and measuring torque resistance within specified tolerances. Both procedures demand careful adherence to torque settings and alignment measurements to maintain steering accuracy and extend component life.

Common Issues and Troubleshooting Tips

Rack and pinion alignment often faces issues like uneven tire wear and steering wheel vibration, typically caused by worn tie rods or misaligned steering racks; checking for loose or damaged components and performing a precise steering geometry adjustment can resolve these problems. Recirculating ball alignment commonly encounters problems such as steering play and difficulty maintaining straight-line tracking, frequently resulting from worn sector shafts or faulty seals; regular inspection and lubrication of ball bearings combined with adjusting the steering box clearance aid in troubleshooting. Both systems benefit from routine maintenance and accurate measurement tools to ensure optimal steering response and vehicle stability.

Which Alignment System Is Best for Your Vehicle?

Rack and pinion alignment offers precise steering control and quicker response, making it ideal for modern vehicles and performance-focused driving. Recirculating ball alignment provides durability and better handling for heavy-duty and off-road vehicles due to its robust design. Choosing the best alignment system depends on your vehicle type, driving conditions, and desired steering performance.

Future Trends in Car Steering Alignment Technologies

Rack and pinion alignment systems are increasingly integrated with advanced electronic sensors and real-time diagnostics, enabling precise calibration that enhances steering responsiveness and safety. Recirculating ball alignment technologies are evolving to support adaptive steering mechanisms in autonomous and electric vehicles, emphasizing durability and workload distribution. Future trends highlight the convergence of AI-driven alignment adjustments and predictive maintenance to optimize steering performance and extend component lifespan.

Rack and Pinion Alignment vs Recirculating Ball Alignment Infographic

cardiffo.com

cardiffo.com