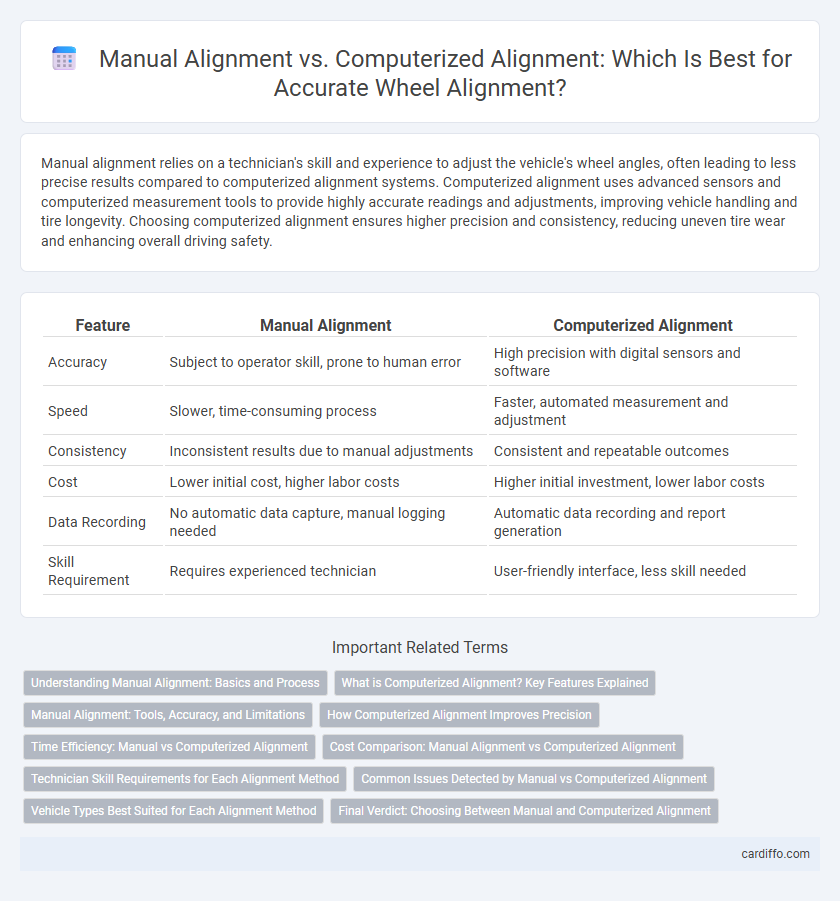

Manual alignment relies on a technician's skill and experience to adjust the vehicle's wheel angles, often leading to less precise results compared to computerized alignment systems. Computerized alignment uses advanced sensors and computerized measurement tools to provide highly accurate readings and adjustments, improving vehicle handling and tire longevity. Choosing computerized alignment ensures higher precision and consistency, reducing uneven tire wear and enhancing overall driving safety.

Table of Comparison

| Feature | Manual Alignment | Computerized Alignment |

|---|---|---|

| Accuracy | Subject to operator skill, prone to human error | High precision with digital sensors and software |

| Speed | Slower, time-consuming process | Faster, automated measurement and adjustment |

| Consistency | Inconsistent results due to manual adjustments | Consistent and repeatable outcomes |

| Cost | Lower initial cost, higher labor costs | Higher initial investment, lower labor costs |

| Data Recording | No automatic data capture, manual logging needed | Automatic data recording and report generation |

| Skill Requirement | Requires experienced technician | User-friendly interface, less skill needed |

Understanding Manual Alignment: Basics and Process

Manual alignment involves adjusting vehicle components by hand using physical tools such as wrenches and alignment gauges to ensure proper tire angles. This process requires skilled technicians to measure and correct camber, caster, and toe settings by visually inspecting and physically manipulating suspension parts. While more time-consuming, manual alignment allows for precise adjustments in situations where computerized systems may not be accessible or suitable.

What is Computerized Alignment? Key Features Explained

Computerized alignment uses advanced sensors and software to measure wheel angles and suspension geometry with high precision, ensuring accurate alignment settings. Key features include real-time digital feedback, automatic calibration, and the ability to store vehicle specifications for consistent results across different makes and models. This technology enhances efficiency, reduces human error, and improves overall vehicle handling and tire longevity.

Manual Alignment: Tools, Accuracy, and Limitations

Manual alignment requires basic tools such as wrenches, dial indicators, and feeler gauges to adjust mechanical components with direct human intervention. Its accuracy depends heavily on operator skill and experience, often resulting in variability and less precision compared to computerized methods. Limitations include time consumption, susceptibility to human error, and difficulty in achieving consistent alignment in complex systems.

How Computerized Alignment Improves Precision

Computerized alignment utilizes advanced sensors and real-time data processing to deliver precision levels unattainable through manual methods, reducing human error significantly. The system's ability to consistently measure alignment angles with increments as small as 0.01 degrees enhances vehicle performance and tire lifespan. Enhanced accuracy in computerized alignment leads to more balanced tire wear, improved fuel efficiency, and safer handling characteristics.

Time Efficiency: Manual vs Computerized Alignment

Computerized alignment significantly reduces time efficiency compared to manual alignment by automating measurements and adjustments with precision software, minimizing human error and repetitive tasks. Manual alignment requires extensive skill and experience, often leading to longer setup and calibration times due to manual measurements and adjustments. Advanced computerized systems can complete alignment processes in a fraction of the time needed for manual methods, improving operational productivity and reducing vehicle downtime.

Cost Comparison: Manual Alignment vs Computerized Alignment

Manual alignment typically incurs lower initial costs due to minimal equipment requirements but may result in higher labor expenses and longer service times. Computerized alignment demands a higher upfront investment in advanced diagnostic tools and software but offers greater precision, faster service, and reduced rework costs. Over time, computerized alignment proves more cost-efficient by minimizing tire wear and enhancing vehicle performance, ultimately lowering maintenance expenses.

Technician Skill Requirements for Each Alignment Method

Manual alignment demands high technician expertise with in-depth knowledge of vehicle suspension geometry and hands-on adjustment skills to achieve precise alignment. Computerized alignment systems reduce skill requirements by providing digital measurements and real-time data, enabling technicians to follow guided steps with greater accuracy. Despite automation benefits, successful computerized alignment still requires technicians to interpret results and perform adjustments accurately.

Common Issues Detected by Manual vs Computerized Alignment

Manual alignment often detects visual irregularities such as uneven tire wear, steering wheel misalignment, and suspension component damage, relying heavily on technician experience and physical measurements. Computerized alignment uses precise sensors and cameras to identify alignment angles like camber, caster, and toe more accurately, uncovering subtle discrepancies that manual methods may miss. While manual alignment can overlook minor deviations, computerized systems provide detailed diagnostics that improve vehicle handling and extend tire life.

Vehicle Types Best Suited for Each Alignment Method

Manual alignment is best suited for classic cars, vintage vehicles, and motorcycles where precision adjustments require hands-on expertise to preserve original specifications. Computerized alignment excels with modern cars, SUVs, and trucks equipped with advanced suspension systems, using sensors and cameras to deliver highly accurate, rapid alignment measurements. Fleet vehicles and commercial trucks benefit significantly from computerized methods due to the need for consistent, repeatable alignment to optimize tire life and vehicle handling.

Final Verdict: Choosing Between Manual and Computerized Alignment

Manual alignment offers precision based on a technician's expertise and is often preferred for unique or older vehicles requiring personalized adjustments. Computerized alignment utilizes advanced sensors and software to deliver consistent, fast, and highly accurate results, ideal for standard modern vehicles. For optimal vehicle performance and longevity, computerized alignment is generally recommended due to its efficiency and superior precision.

Manual Alignment vs Computerized Alignment Infographic

cardiffo.com

cardiffo.com