Brake pad replacement involves installing new pads to restore braking efficiency, while rotor machining resurfaces the existing rotors to eliminate grooves and warping. Choosing between the two depends on rotor thickness and damage severity; machining extends rotor life but may not be feasible if the rotor is too thin. Regular maintenance ensures safe and effective braking performance, especially important for service vehicles carrying pets.

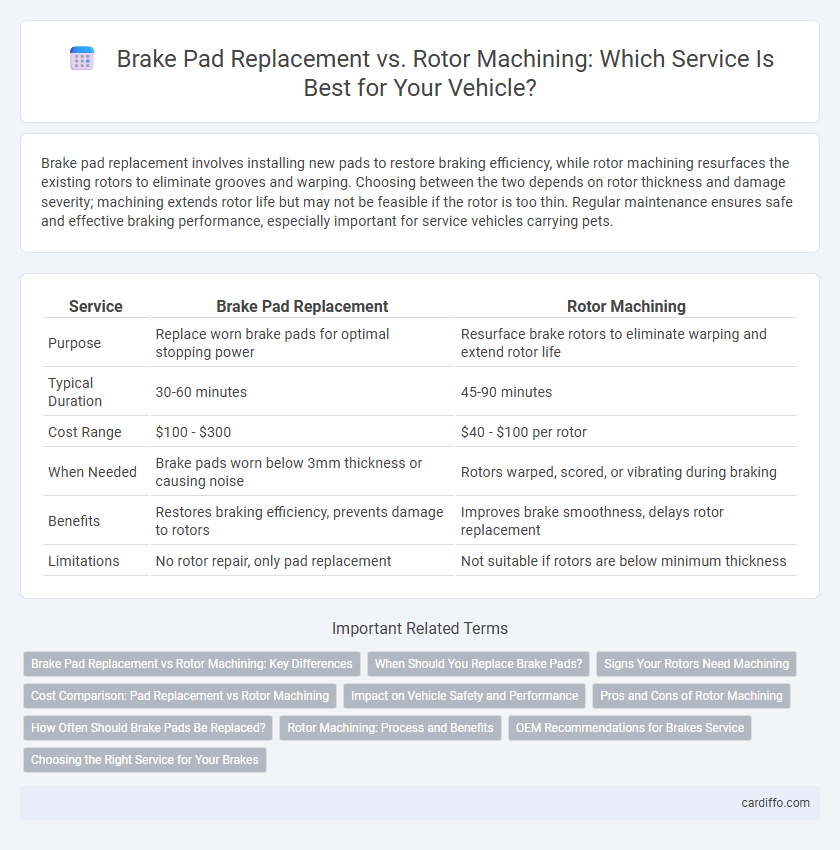

Table of Comparison

| Service | Brake Pad Replacement | Rotor Machining |

|---|---|---|

| Purpose | Replace worn brake pads for optimal stopping power | Resurface brake rotors to eliminate warping and extend rotor life |

| Typical Duration | 30-60 minutes | 45-90 minutes |

| Cost Range | $100 - $300 | $40 - $100 per rotor |

| When Needed | Brake pads worn below 3mm thickness or causing noise | Rotors warped, scored, or vibrating during braking |

| Benefits | Restores braking efficiency, prevents damage to rotors | Improves brake smoothness, delays rotor replacement |

| Limitations | No rotor repair, only pad replacement | Not suitable if rotors are below minimum thickness |

Brake Pad Replacement vs Rotor Machining: Key Differences

Brake pad replacement involves removing worn brake pads and installing new ones to ensure effective braking performance and safety. Rotor machining, or resurfacing, entails grinding the brake rotors to eliminate grooves, warping, and uneven surfaces, restoring smooth contact with the brake pads. Choosing brake pad replacement versus rotor machining depends on rotor thickness, damage severity, and manufacturer specifications to maintain optimal braking system functionality.

When Should You Replace Brake Pads?

Brake pads should be replaced when their thickness is less than 3 millimeters or if you hear squealing or grinding noises during braking, indicating wear. Replacing brake pads promptly prevents damage to the rotors, which can lead to more expensive repairs like rotor machining or replacement. Regular inspections every 10,000 to 15,000 miles help determine the optimal timing for brake pad replacement to maintain safe braking performance.

Signs Your Rotors Need Machining

Worn or scored rotors often cause vibrations during braking and uneven brake pad wear, indicating the need for rotor machining. Deep grooves, excessive thickness variation, or a pulsating brake pedal also signal rotor surface irregularities that machining can address. Machining restores a smooth surface, ensuring optimal brake performance and prolonging the life of both rotors and brake pads.

Cost Comparison: Pad Replacement vs Rotor Machining

Brake pad replacement typically costs between $150 and $300, making it a more budget-friendly option compared to rotor machining, which ranges from $200 to $400 per axle. Rotor machining extends the life of the rotors by resurfacing but may require future replacement sooner than new rotors paired with new pads. Choosing pad replacement over rotor machining often results in lower immediate expenses, while machining can delay the need for full rotor replacement, impacting overall maintenance costs.

Impact on Vehicle Safety and Performance

Brake pad replacement directly restores optimal friction levels, ensuring reliable stopping power and maintaining vehicle safety. Rotor machining smooths out surface imperfections to prolong rotor life but may reduce rotor thickness, potentially affecting heat dissipation and braking performance. Choosing the appropriate service balances safety and efficiency by preserving braking system integrity and preventing premature wear.

Pros and Cons of Rotor Machining

Rotor machining can restore uneven or slightly warped brake rotors by removing surface imperfections and extending rotor lifespan, offering a cost-effective alternative to replacement. However, this process reduces rotor thickness, potentially leading to diminished heat dissipation and increased risk of rotor failure if thickness falls below manufacturer specifications. Frequent machining may result in compromised braking performance and safety concerns, making rotor replacement a preferable option for severely damaged rotors.

How Often Should Brake Pads Be Replaced?

Brake pads should typically be replaced every 30,000 to 70,000 miles, depending on driving habits and vehicle type. Inspecting brake pads during regular maintenance helps determine if replacement is necessary to prevent rotor damage. Worn brake pads combined with rotor machining can restore braking efficiency and extend the life of the braking system.

Rotor Machining: Process and Benefits

Rotor machining involves resurfacing the brake rotors to restore a smooth, even surface by removing minor grooves and imperfections, improving contact with brake pads. This process extends rotor lifespan, reduces brake vibration, and enhances overall braking performance without the need for full rotor replacement. Proper rotor machining ensures cost-effective maintenance while maintaining vehicle safety and optimal stopping power.

OEM Recommendations for Brakes Service

OEM recommendations emphasize replacing brake pads while inspecting rotors for wear and damage to ensure optimal braking performance and safety. Rotor machining, or resurfacing, is typically advised only if the rotors meet minimum thickness specifications and exhibit minor surface irregularities. Strict adherence to OEM guidelines prevents compromised braking efficiency and extends the lifespan of braking system components.

Choosing the Right Service for Your Brakes

Brake pad replacement restores friction material essential for safe stopping, while rotor machining resurfaces the brake rotors to eliminate grooves and uneven wear. Choosing between the two depends on rotor thickness, damage severity, and manufacturer specifications, as excessively thin rotors compromise braking performance and safety. Prioritizing pad replacement when rotors remain within tolerance preserves braking efficiency, whereas machining is cost-effective only if rotors meet minimum thickness standards without structural issues.

Brake pad replacement vs Rotor machining Infographic

cardiffo.com

cardiffo.com