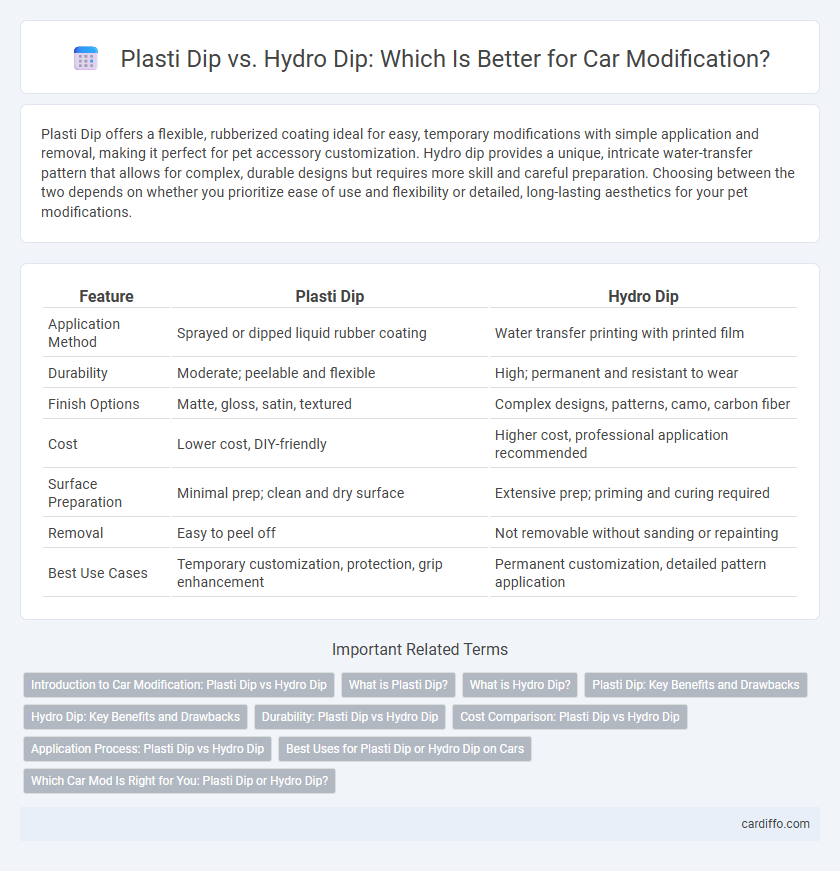

Plasti Dip offers a flexible, rubberized coating ideal for easy, temporary modifications with simple application and removal, making it perfect for pet accessory customization. Hydro dip provides a unique, intricate water-transfer pattern that allows for complex, durable designs but requires more skill and careful preparation. Choosing between the two depends on whether you prioritize ease of use and flexibility or detailed, long-lasting aesthetics for your pet modifications.

Table of Comparison

| Feature | Plasti Dip | Hydro Dip |

|---|---|---|

| Application Method | Sprayed or dipped liquid rubber coating | Water transfer printing with printed film |

| Durability | Moderate; peelable and flexible | High; permanent and resistant to wear |

| Finish Options | Matte, gloss, satin, textured | Complex designs, patterns, camo, carbon fiber |

| Cost | Lower cost, DIY-friendly | Higher cost, professional application recommended |

| Surface Preparation | Minimal prep; clean and dry surface | Extensive prep; priming and curing required |

| Removal | Easy to peel off | Not removable without sanding or repainting |

| Best Use Cases | Temporary customization, protection, grip enhancement | Permanent customization, detailed pattern application |

Introduction to Car Modification: Plasti Dip vs Hydro Dip

Plasti Dip offers a flexible, removable rubber coating ideal for temporary car modifications, providing protection and color changes without damaging the original paint. Hydro dip uses water transfer printing to apply intricate, permanent patterns and designs, allowing for highly detailed custom finishes on car parts. Both techniques enable unique aesthetic enhancements but differ significantly in application method, durability, and visual complexity.

What is Plasti Dip?

Plasti Dip is a versatile, rubberized coating composed of synthetic elastomer that provides a removable and protective layer on surfaces. It is commonly used in automotive modification to temporarily change color or texture without damaging the original paint. This air-dry coating is resistant to moisture, acids, corrosion, and skidding, making it ideal for customization and surface protection.

What is Hydro Dip?

Hydro dip, also known as water transfer printing, is a surface modification technique that applies intricate patterns onto three-dimensional objects by dipping them into a water film containing printed designs. This method allows for detailed customization on materials like plastic, metal, and wood, providing a durable and visually striking finish. Unlike plasti dip, which is a rubberized coating applied by spraying or dipping, hydro dipping embeds the design seamlessly under a clear protective layer.

Plasti Dip: Key Benefits and Drawbacks

Plasti Dip offers a flexible, rubberized coating that provides excellent protection against moisture, abrasion, and corrosion while allowing easy removal without damaging the original surface. It is ideal for temporary customization and maintenance tasks due to its quick drying time and affordability. However, its durability is lower compared to hydro dipping, especially in high-friction or outdoor environments where prolonged exposure can lead to peeling and fading.

Hydro Dip: Key Benefits and Drawbacks

Hydro dip offers intricate, customizable designs with a smooth, uniform finish that easily adheres to complex surfaces, making it ideal for automotive and consumer goods modifications. The process is efficient for large-scale, multi-color patterns but requires thorough surface cleaning and can be sensitive to environmental conditions, potentially affecting durability. Despite its versatility, hydro dipping may involve higher costs and longer curing times compared to alternatives like Plasti Dip.

Durability: Plasti Dip vs Hydro Dip

Plasti Dip offers strong resistance to peeling, chipping, and UV damage, making it ideal for temporary or semi-permanent vehicle customization. Hydro Dip provides a durable, permanent finish resistant to harsh weather conditions and daily wear, but it may be vulnerable to scratches without a clear coat layer. Both methods enhance surface protection, however, Hydro Dip generally delivers longer-lasting durability under heavy use.

Cost Comparison: Plasti Dip vs Hydro Dip

Plasti Dip typically costs between $15 to $30 per spray can, making it a budget-friendly option for DIY vehicle modifications, while hydro dip pricing ranges from $300 to $600 per panel due to professional application and specialized equipment. The overall expense for Plasti Dip is lower because it involves fewer materials and no need for outsourcing, whereas hydro dipping includes additional costs such as custom film design and dipping services. Choosing between these coating methods depends on budget constraints and desired finish complexity, with Plasti Dip favoring affordability and hydro dip offering premium aesthetics.

Application Process: Plasti Dip vs Hydro Dip

Plasti Dip application involves spraying multiple coats of a rubberized liquid coating, allowing each layer to dry for a peelable, flexible finish ideal for temporary or customizable protection. Hydro dipping requires submerging a primed object into water with a floating film of printed design, which adheres as the film dissolves, creating a durable, seamless patterned surface. Both processes demand surface preparation but differ significantly in equipment, curing time, and the complexity of achievable designs.

Best Uses for Plasti Dip or Hydro Dip on Cars

Plasti Dip is best used on cars for temporary customization, protection of wheels, badges, and trim with easy peel-off capability, making it ideal for seasonal changes or testing new colors. Hydro Dip excels in applying intricate, multicolor designs on smaller parts like interior panels, engine covers, and accessories, offering long-lasting, durable finishes with high visual impact. Both methods provide unique aesthetic enhancements but differ in permanence and complexity, suitable for distinct automotive modification needs.

Which Car Mod Is Right for You: Plasti Dip or Hydro Dip?

Plasti Dip offers a removable, cost-effective solution ideal for temporary or experimental car modifications, providing a matte or satin finish that protects the original paint. Hydro Dip, or water transfer printing, delivers intricate, permanent designs with a wide range of patterns and a glossy finish, making it suitable for detailed customization on various car parts. Choosing between Plasti Dip and Hydro Dip depends on your budget, desired durability, and the complexity of the design you want to achieve.

plasti dip vs hydro dip Infographic

cardiffo.com

cardiffo.com