Air suspension offers adjustable ride height and improved comfort by inflating air springs, making it ideal for daily driving and cruising. Hydraulic suspension provides faster response and greater load capacity by using fluid-filled cylinders, preferred for performance modifications and heavy-duty applications. Choosing between air and hydraulic suspension depends on whether you prioritize smooth ride quality or dynamic handling and load support.

Table of Comparison

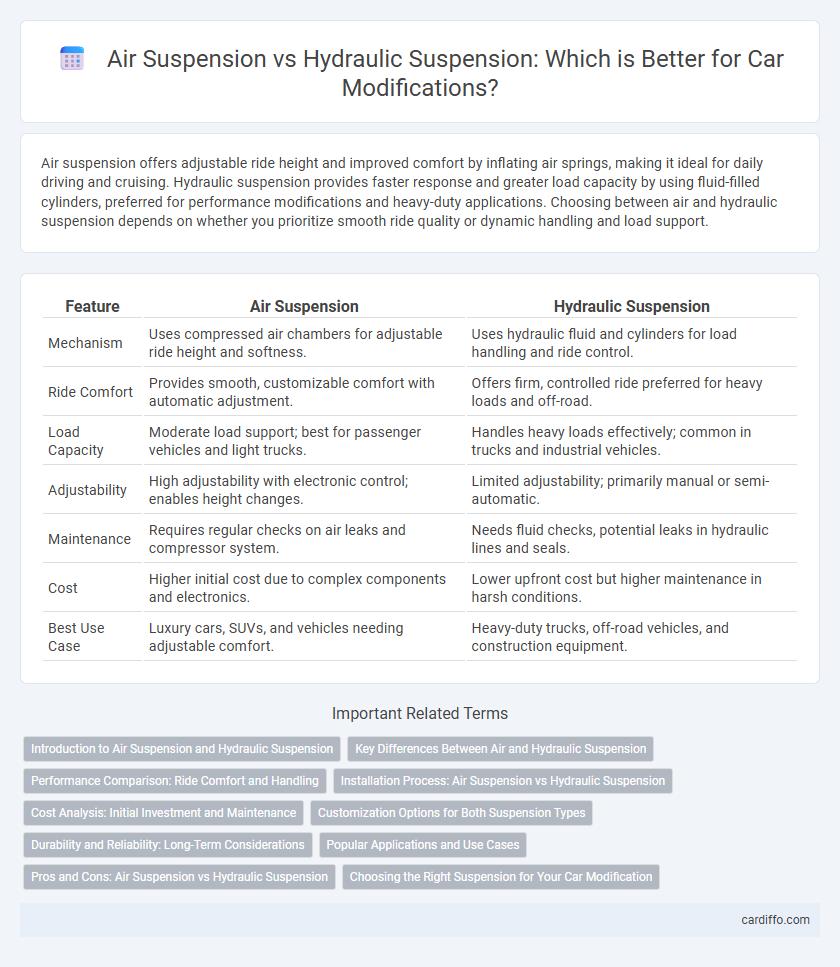

| Feature | Air Suspension | Hydraulic Suspension |

|---|---|---|

| Mechanism | Uses compressed air chambers for adjustable ride height and softness. | Uses hydraulic fluid and cylinders for load handling and ride control. |

| Ride Comfort | Provides smooth, customizable comfort with automatic adjustment. | Offers firm, controlled ride preferred for heavy loads and off-road. |

| Load Capacity | Moderate load support; best for passenger vehicles and light trucks. | Handles heavy loads effectively; common in trucks and industrial vehicles. |

| Adjustability | High adjustability with electronic control; enables height changes. | Limited adjustability; primarily manual or semi-automatic. |

| Maintenance | Requires regular checks on air leaks and compressor system. | Needs fluid checks, potential leaks in hydraulic lines and seals. |

| Cost | Higher initial cost due to complex components and electronics. | Lower upfront cost but higher maintenance in harsh conditions. |

| Best Use Case | Luxury cars, SUVs, and vehicles needing adjustable comfort. | Heavy-duty trucks, off-road vehicles, and construction equipment. |

Introduction to Air Suspension and Hydraulic Suspension

Air suspension and hydraulic suspension are advanced vehicle suspension systems designed to improve ride comfort and handling. Air suspension uses compressed air springs that adjust to different loads and road conditions, offering a smoother, more customizable ride. Hydraulic suspension employs fluid-filled cylinders to provide precise control of vehicle height and damping, enhancing stability and responsiveness during driving.

Key Differences Between Air and Hydraulic Suspension

Air suspension uses compressed air stored in flexible bags to provide adjustable ride height and smoothness, while hydraulic suspension relies on fluid-filled cylinders offering precise damping control and load-bearing capacity. Air suspension systems excel in comfort and adaptability for varying terrains, whereas hydraulic suspensions deliver superior stability and performance under heavy loads and high-speed conditions. The key differences center on air suspension's flexibility and ease of adjustment versus hydraulic suspension's strength and responsiveness.

Performance Comparison: Ride Comfort and Handling

Air suspension systems provide superior ride comfort by automatically adjusting to road conditions and vehicle load, ensuring a smoother experience over varied terrains. Hydraulic suspension, known for its precise handling and rapid response, excels in performance driving scenarios requiring quick adjustments and enhanced stability. Comparing the two, air suspension emphasizes comfort and adaptability, while hydraulic suspension prioritizes agility and control for performance-focused applications.

Installation Process: Air Suspension vs Hydraulic Suspension

The installation process of air suspension involves mounting air springs, compressors, air tanks, and intricate wiring for controls, requiring precise calibration for proper ride height and pressure management. Hydraulic suspension installation demands integrating pumps, reservoirs, hydraulic lines, and control valves, with careful attention to fluid sealing and pressure settings to ensure system responsiveness. Air suspension systems generally offer more modular installation with electronic controls, whereas hydraulic setups involve more complex plumbing and mechanical adjustments for durability and performance.

Cost Analysis: Initial Investment and Maintenance

Air suspension systems typically entail higher initial investment costs compared to hydraulic suspensions due to advanced components and technology. Maintenance expenses for air suspension can be more costly over time because of the need for specialized repairs and air compressor upkeep. In contrast, hydraulic suspension systems often have lower upfront costs and simpler maintenance, making them a cost-effective choice for budget-conscious modifications.

Customization Options for Both Suspension Types

Air suspension systems offer extensive customization through adjustable ride height, air pressure settings, and programmable damping, allowing precise control over vehicle comfort and performance. Hydraulic suspension customization includes adjustable fluid pressure and flow rates, enabling rapid height changes and enhanced load handling for specialized applications. Both suspension types support tailored tuning, but air suspension excels in ride smoothness and height variability, while hydraulic systems prioritize responsiveness and load-bearing adaptability.

Durability and Reliability: Long-Term Considerations

Air suspension systems offer enhanced adjustability but may experience more frequent maintenance issues due to air leaks and compressor wear, impacting long-term durability. Hydraulic suspension systems deliver robust performance with fewer moving parts, translating into higher reliability and extended lifespan under heavy-duty conditions. Choosing between the two systems depends on balancing performance needs against maintenance demands and durability expectations for long-term vehicle modification.

Popular Applications and Use Cases

Air suspension systems are widely used in luxury vehicles and performance cars for adjustable ride height and improved comfort, providing superior adaptability in urban driving and long-distance travel. Hydraulic suspension is popular in heavy-duty trucks and off-road vehicles where enhanced load-bearing capacity and shock absorption are essential for rugged terrain and towing. Both systems are favored in custom automotive modifications for their ability to tailor ride quality and vehicle stance according to specific use cases.

Pros and Cons: Air Suspension vs Hydraulic Suspension

Air suspension offers superior ride comfort, adjustable ride height, and improved load leveling, making it ideal for varying road conditions and heavy loads; however, it tends to be more expensive and requires regular maintenance due to potential air leaks. Hydraulic suspension provides excellent stability, rapid response, and enhanced handling performance, especially in off-road or high-performance applications, but it is often heavier, less adjustable, and can be prone to fluid leaks and mechanical complexity. Choosing between air suspension and hydraulic suspension depends on balancing the need for comfort, adjustability, and load capacity against cost, maintenance, and performance requirements.

Choosing the Right Suspension for Your Car Modification

Selecting the right suspension for your car modification hinges on factors such as ride comfort, load capacity, and adjustability. Air suspension systems offer superior ride quality and customizable height adjustments, making them ideal for urban driving and show cars. Hydraulic suspension provides more precise control and durability for heavy loads and off-road capabilities, suitable for performance-focused or rugged vehicle builds.

air suspension vs hydraulic suspension Infographic

cardiffo.com

cardiffo.com