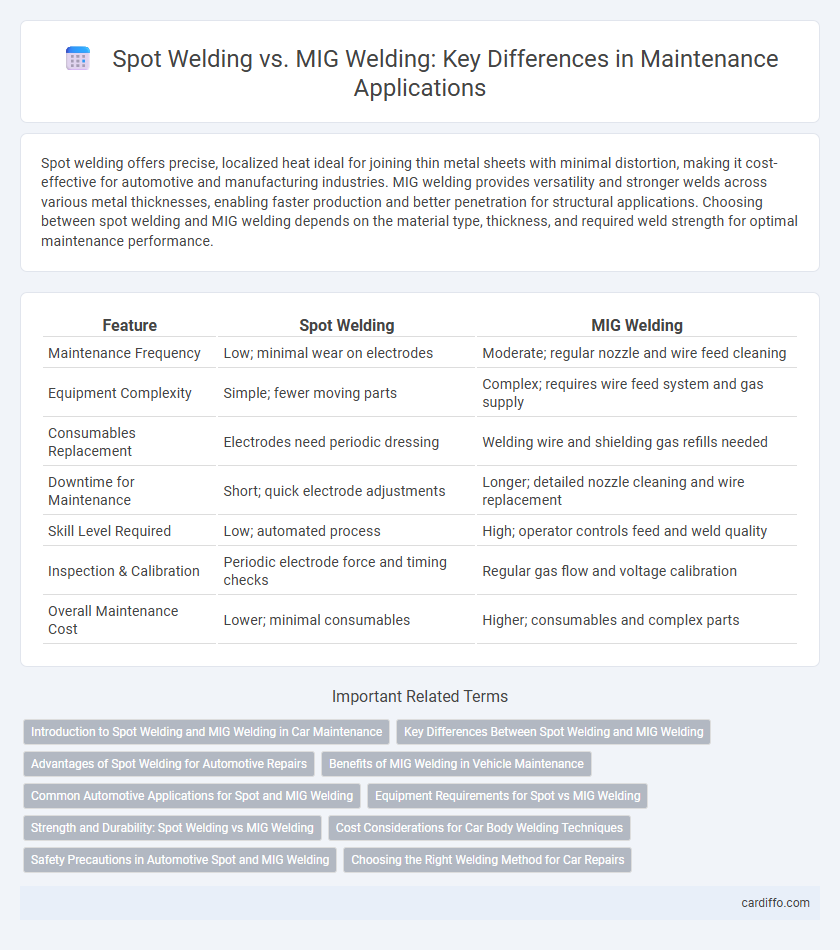

Spot welding offers precise, localized heat ideal for joining thin metal sheets with minimal distortion, making it cost-effective for automotive and manufacturing industries. MIG welding provides versatility and stronger welds across various metal thicknesses, enabling faster production and better penetration for structural applications. Choosing between spot welding and MIG welding depends on the material type, thickness, and required weld strength for optimal maintenance performance.

Table of Comparison

| Feature | Spot Welding | MIG Welding |

|---|---|---|

| Maintenance Frequency | Low; minimal wear on electrodes | Moderate; regular nozzle and wire feed cleaning |

| Equipment Complexity | Simple; fewer moving parts | Complex; requires wire feed system and gas supply |

| Consumables Replacement | Electrodes need periodic dressing | Welding wire and shielding gas refills needed |

| Downtime for Maintenance | Short; quick electrode adjustments | Longer; detailed nozzle cleaning and wire replacement |

| Skill Level Required | Low; automated process | High; operator controls feed and weld quality |

| Inspection & Calibration | Periodic electrode force and timing checks | Regular gas flow and voltage calibration |

| Overall Maintenance Cost | Lower; minimal consumables | Higher; consumables and complex parts |

Introduction to Spot Welding and MIG Welding in Car Maintenance

Spot welding is a resistance welding technique widely used in car maintenance to join metal sheets with precise, localized heat, making it ideal for assembling car body panels. MIG (Metal Inert Gas) welding uses a continuous wire feed and inert gas to create strong, clean welds suitable for repairing chassis components and structural parts. Both methods are essential in automotive repair, with spot welding preferred for factory-like sheet metal joints and MIG welding favored for versatile, durable repairs.

Key Differences Between Spot Welding and MIG Welding

Spot welding uses electric current to join metal surfaces at localized points, making it ideal for thin sheet metals and rapid assembly processes. MIG welding employs a continuous wire feed and shielding gas, allowing for deeper penetration and versatility across various metal thicknesses. Key differences include spot welding's focus on speed and precision in sheet metal fabrication versus MIG welding's adaptability for stronger, more extensive structural joins.

Advantages of Spot Welding for Automotive Repairs

Spot welding offers superior speed and efficiency in automotive repairs by creating strong, consistent welds at multiple points simultaneously, reducing labor time and improving structural integrity. This technique minimizes metal distortion and heat-affected zones compared to MIG welding, preserving the original material properties and ensuring better fitment of auto body panels. Its suitability for thin gauge metals commonly used in vehicle bodies makes spot welding an essential method for cost-effective and reliable automotive maintenance.

Benefits of MIG Welding in Vehicle Maintenance

MIG welding offers superior versatility and speed, making it ideal for vehicle maintenance where diverse metal types and thicknesses are common. Its continuous wire feed delivers consistent, high-quality welds, reducing repair time and improving structural integrity. The process produces cleaner welds with less spatter, minimizing post-weld cleanup and enhancing overall efficiency.

Common Automotive Applications for Spot and MIG Welding

Spot welding is extensively used in automotive manufacturing for joining sheet metal components such as car body panels, doors, and chassis parts due to its speed and strong, localized welds. MIG welding is commonly applied in automotive maintenance and repairs for fabricating exhaust systems, frames, and structural components where thicker metals require deeper penetration and flexibility. Both welding methods optimize durability and efficiency in automotive assembly and repair, with spot welding favored for mass production and MIG welding chosen for precision and versatility in maintenance tasks.

Equipment Requirements for Spot vs MIG Welding

Spot welding equipment requires a specialized resistance welding machine with electrode arms and a transformer to deliver high current in short bursts, emphasizing precision and minimal material distortion. MIG welding demands a welding power source, a wire feeder, a welding gun, and shielding gas delivery systems to enable continuous wire feeding and stable arc performance. The complexity and size of MIG welding setups generally exceed spot welding machines, reflecting differing operational needs and maintenance considerations.

Strength and Durability: Spot Welding vs MIG Welding

Spot welding offers superior strength and durability for joining thin metal sheets by creating localized welds that maintain the metal's integrity with minimal distortion. MIG welding provides robust, continuous welds suitable for thicker metals, delivering high tensile strength and enhanced durability in structural applications. Both methods ensure strong joints, but spot welding excels in precision and resistance to fatigue, while MIG welding is preferred for heavy-duty and multi-pass welding tasks.

Cost Considerations for Car Body Welding Techniques

Spot welding generally offers lower operational costs for car body welding due to faster cycle times and minimal material waste, making it ideal for high-volume production. MIG welding, while more expensive with higher consumable costs like shielding gas and wire, provides greater versatility for complex joint designs and repair work. Maintenance expenses for spot welding equipment tend to be lower compared to MIG welding systems that require regular calibration and consumable replacement.

Safety Precautions in Automotive Spot and MIG Welding

Spot welding in automotive applications requires strict safety precautions such as wearing insulated gloves and safety glasses to protect against electric shock and molten metal splatter. MIG welding demands proper ventilation to avoid inhalation of hazardous fumes, along with flame-resistant clothing and gloves to shield from high heat and UV radiation. Both welding methods necessitate regular inspection of equipment to prevent malfunctions and ensure operator safety on the job.

Choosing the Right Welding Method for Car Repairs

Spot welding excels in automotive maintenance for joining sheet metal panels quickly and with strong, localized heat, making it ideal for body repairs and frame assembly. MIG welding offers greater versatility and deeper penetration, suitable for structural repairs and thicker metals in car maintenance tasks. Selecting the right welding method depends on material thickness, repair location, and desired weld strength, optimizing durability and repair efficiency.

Spot Welding vs MIG Welding Infographic

cardiffo.com

cardiffo.com