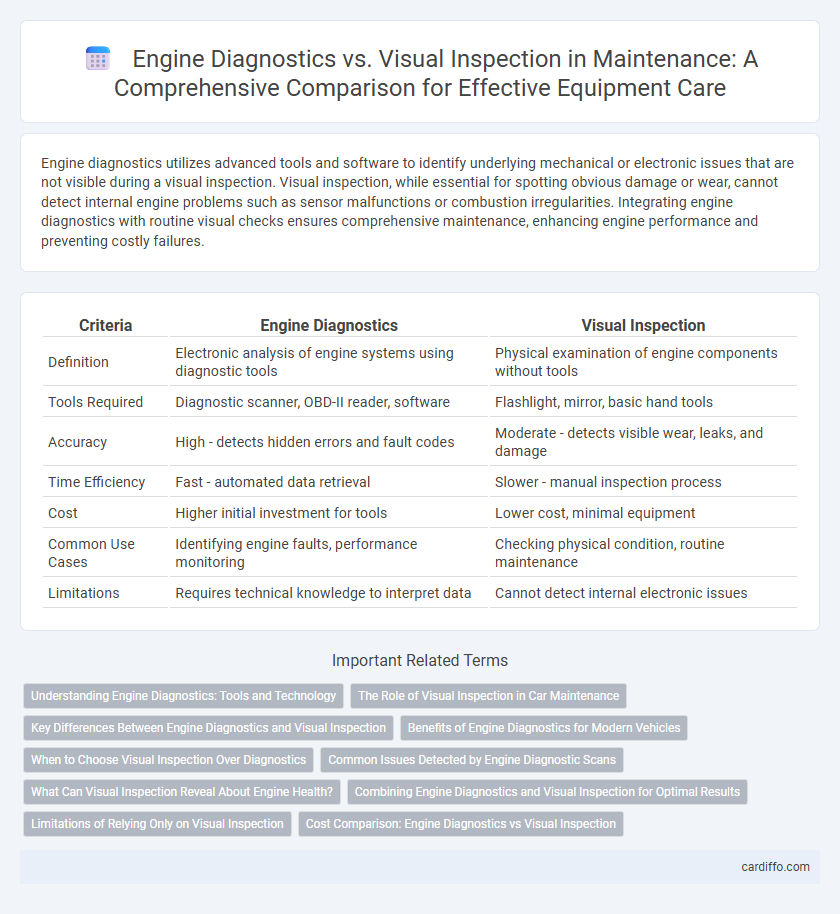

Engine diagnostics utilizes advanced tools and software to identify underlying mechanical or electronic issues that are not visible during a visual inspection. Visual inspection, while essential for spotting obvious damage or wear, cannot detect internal engine problems such as sensor malfunctions or combustion irregularities. Integrating engine diagnostics with routine visual checks ensures comprehensive maintenance, enhancing engine performance and preventing costly failures.

Table of Comparison

| Criteria | Engine Diagnostics | Visual Inspection |

|---|---|---|

| Definition | Electronic analysis of engine systems using diagnostic tools | Physical examination of engine components without tools |

| Tools Required | Diagnostic scanner, OBD-II reader, software | Flashlight, mirror, basic hand tools |

| Accuracy | High - detects hidden errors and fault codes | Moderate - detects visible wear, leaks, and damage |

| Time Efficiency | Fast - automated data retrieval | Slower - manual inspection process |

| Cost | Higher initial investment for tools | Lower cost, minimal equipment |

| Common Use Cases | Identifying engine faults, performance monitoring | Checking physical condition, routine maintenance |

| Limitations | Requires technical knowledge to interpret data | Cannot detect internal electronic issues |

Understanding Engine Diagnostics: Tools and Technology

Engine diagnostics utilize advanced tools such as OBD-II scanners, thermal imaging cameras, and vibration analyzers to detect internal issues that are not visible through a visual inspection. These technologies provide real-time data on engine performance, error codes, and system malfunctions, enabling precise identification of faults. Visual inspections, while essential for examining external components and physical damage, cannot match the depth of information extracted from electronic diagnostic tools.

The Role of Visual Inspection in Car Maintenance

Visual inspection plays a critical role in car maintenance by identifying obvious signs of wear, leaks, or damage that engine diagnostics may not detect. It allows mechanics to assess physical conditions such as belt tension, fluid levels, and corrosion, providing immediate insights without the need for specialized equipment. Regular visual checks complement engine diagnostics by ensuring potential issues are caught early, maintaining vehicle reliability and safety.

Key Differences Between Engine Diagnostics and Visual Inspection

Engine diagnostics utilize advanced electronic tools and software to detect and analyze engine performance issues, providing precise data on sensor readings and fault codes. Visual inspection relies on manual examination of engine components for visible signs of wear, leaks, or damage but lacks the ability to identify hidden or electronic malfunctions. Combining both methods enhances maintenance accuracy by addressing both mechanical condition and electronic system integrity.

Benefits of Engine Diagnostics for Modern Vehicles

Engine diagnostics offer precise identification of internal issues that visual inspections often miss, enabling targeted repairs and reducing downtime. Modern vehicles equipped with advanced sensors provide real-time data, allowing for predictive maintenance and preventing costly breakdowns. This technology enhances accuracy, efficiency, and overall vehicle reliability compared to traditional visual methods.

When to Choose Visual Inspection Over Diagnostics

Visual inspection is ideal when immediate, low-cost assessment is needed for obvious issues such as leaks, corrosion, or physical damage to engine components. It effectively identifies surface-level problems not easily detected by engine diagnostics, especially in older models lacking advanced sensor systems. Choose visual inspection when diagnostics yield ambiguous results or when quick on-site evaluation is essential to prevent downtime and expedite repairs.

Common Issues Detected by Engine Diagnostic Scans

Engine diagnostic scans effectively identify common issues such as misfires, sensor malfunctions, and fuel system irregularities that often go unnoticed during visual inspections. These scans detect error codes related to the engine control unit (ECU), enabling precise troubleshooting of ignition problems, oxygen sensor failures, and catalytic converter performance. Visual inspections, while useful for identifying external damages and fluid leaks, cannot match the depth of internal engine fault detection provided by diagnostic tools.

What Can Visual Inspection Reveal About Engine Health?

Visual inspection can reveal critical engine health indicators such as oil leaks, corrosion, worn belts, and damaged hoses, which may signal underlying mechanical issues. It helps identify visible signs of overheating, fluid contamination, and loose connections that can affect engine performance. Regular visual checks provide immediate detection of external damages that might not yet trigger diagnostic codes but require prompt attention to prevent severe engine failure.

Combining Engine Diagnostics and Visual Inspection for Optimal Results

Combining engine diagnostics and visual inspection enhances maintenance accuracy by leveraging real-time data analysis alongside direct component evaluation. Engine diagnostics identify fault codes, performance issues, and sensor data anomalies, while visual inspection detects physical damage, wear, and leaks. Integrating both methods ensures comprehensive troubleshooting, reduces downtime, and extends engine longevity.

Limitations of Relying Only on Visual Inspection

Visual inspection for engine diagnostics fails to detect internal faults such as sensor malfunctions, combustion irregularities, or subtle wear in engine components that do not present visible symptoms. Without the use of advanced diagnostic tools like OBD-II scanners and thermal imaging, critical issues like misfires, fuel injection problems, and software errors remain undiscovered, leading to potential engine failure. Solely relying on visual inspection compromises accuracy and may result in increased repair costs and unexpected downtime.

Cost Comparison: Engine Diagnostics vs Visual Inspection

Engine diagnostics typically involve advanced tools and software, resulting in higher initial costs compared to visual inspections, which rely on manual observation and require minimal equipment. Despite the higher upfront expense, engine diagnostics can identify hidden or complex issues more accurately, potentially reducing long-term maintenance costs by preventing major engine failures. Visual inspections, while cost-effective for routine checks, may miss subtle faults, leading to more costly repairs over time due to undetected problems.

Engine Diagnostics vs Visual Inspection Infographic

cardiffo.com

cardiffo.com