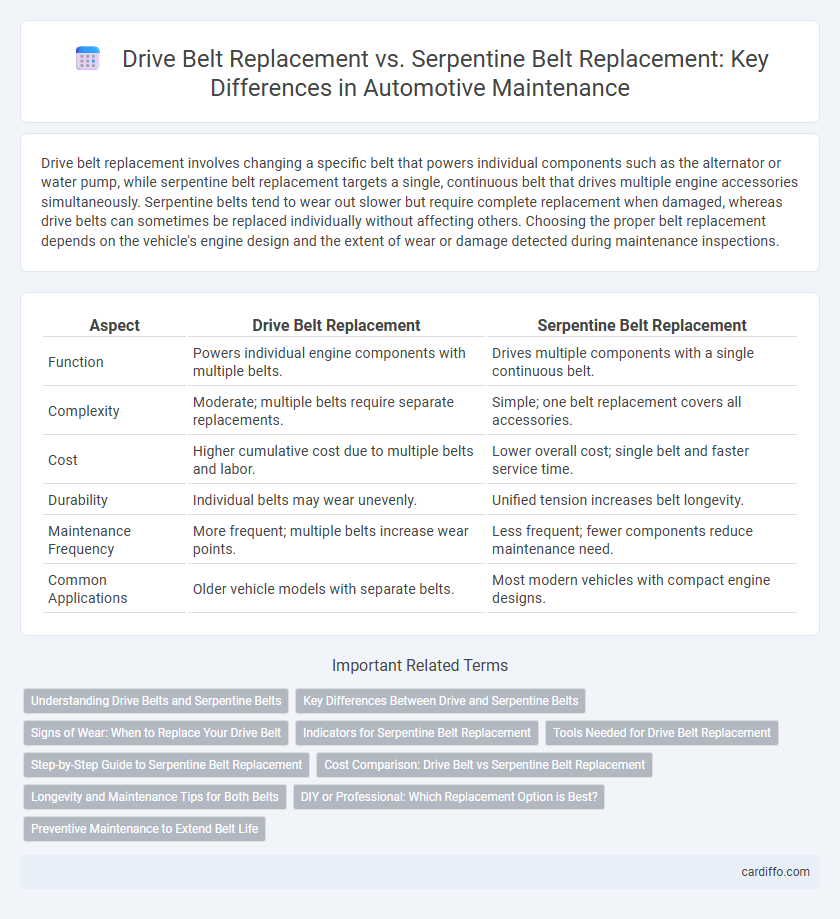

Drive belt replacement involves changing a specific belt that powers individual components such as the alternator or water pump, while serpentine belt replacement targets a single, continuous belt that drives multiple engine accessories simultaneously. Serpentine belts tend to wear out slower but require complete replacement when damaged, whereas drive belts can sometimes be replaced individually without affecting others. Choosing the proper belt replacement depends on the vehicle's engine design and the extent of wear or damage detected during maintenance inspections.

Table of Comparison

| Aspect | Drive Belt Replacement | Serpentine Belt Replacement |

|---|---|---|

| Function | Powers individual engine components with multiple belts. | Drives multiple components with a single continuous belt. |

| Complexity | Moderate; multiple belts require separate replacements. | Simple; one belt replacement covers all accessories. |

| Cost | Higher cumulative cost due to multiple belts and labor. | Lower overall cost; single belt and faster service time. |

| Durability | Individual belts may wear unevenly. | Unified tension increases belt longevity. |

| Maintenance Frequency | More frequent; multiple belts increase wear points. | Less frequent; fewer components reduce maintenance need. |

| Common Applications | Older vehicle models with separate belts. | Most modern vehicles with compact engine designs. |

Understanding Drive Belts and Serpentine Belts

Drive belts and serpentine belts are essential components in vehicle engine systems, responsible for transferring power to various accessories like the alternator, power steering pump, and air conditioning compressor. Drive belts are typically single V-shaped belts that operate individual components, whereas serpentine belts are long, continuous belts that wind through multiple pulleys, enhancing efficiency and reducing the need for multiple belts. Understanding the structure and function of each belt type is crucial for timely replacement and maintaining optimal engine performance.

Key Differences Between Drive and Serpentine Belts

Drive belts and serpentine belts differ primarily in design and function; drive belts typically power individual components with separate belts, while serpentine belts operate multiple accessories simultaneously using a single, continuous belt. Serpentine belts tend to be wider and smoother, improving durability and reducing slippage compared to the narrower, sometimes ribbed drive belts. Maintenance requirements also vary, as serpentine belts often feature automatic tensioners, whereas drive belts require manual adjustment.

Signs of Wear: When to Replace Your Drive Belt

Signs of wear on a drive belt include visible cracks, fraying, glazing, or a squealing noise during engine operation, indicating imminent failure. Serpentine belts, although more durable, show wear through these same symptoms as well as loss of tension or misalignment causing slippage. Regular inspection at intervals of 60,000 to 100,000 miles ensures timely replacement, preventing engine accessory malfunction and costly repairs.

Indicators for Serpentine Belt Replacement

Worn serpentine belts exhibit visible cracks, fraying, or glazing on the surface, indicating replacement necessity. Squealing noises during engine operation often signal belt slippage or deterioration, requiring immediate attention. Vehicle systems powered by the serpentine belt, such as the alternator or air conditioning compressor, losing functionality can also indicate the belt's imminent failure.

Tools Needed for Drive Belt Replacement

Drive belt replacement requires basic automotive tools such as a socket wrench set, a belt tensioner tool, and possibly a pry bar to relieve tension on the belt. Unlike serpentine belts that may need specialized tools for tensioner adjustment, drive belts often use manual tensioners that simplify the replacement process. Having accurate tools ensures proper installation and optimal engine performance.

Step-by-Step Guide to Serpentine Belt Replacement

Serpentine belt replacement involves a precise step-by-step process starting with locating the belt routing diagram, usually found under the hood or in the vehicle manual, to ensure proper installation. Begin by loosening the tensioner using a wrench or serpentine belt tool to relieve tension on the belt, then carefully remove the old belt from the pulleys. Install the new serpentine belt by following the routing diagram, ensuring it sits correctly on each pulley before releasing the tensioner to secure the belt in place, and finally inspect for proper alignment and tension to prevent premature wear or slippage.

Cost Comparison: Drive Belt vs Serpentine Belt Replacement

Drive belt replacement typically costs between $50 and $150, reflecting the lower complexity and fewer components involved compared to serpentine belt replacement, which ranges from $100 to $250 due to the belt's larger size and additional accessories it powers. Labor costs for serpentine belt replacement are generally higher because the process involves navigating multiple pulleys and tensioners, extending service time. Choosing between the two depends on vehicle type, belt condition, and repair urgency, with serpentine belts often requiring more frequent and costly maintenance due to their critical role in engine performance.

Longevity and Maintenance Tips for Both Belts

Drive belt replacement and serpentine belt replacement differ significantly in longevity, with serpentine belts typically lasting between 50,000 to 100,000 miles due to their durable EPDM rubber composition, while traditional drive belts often require replacement every 30,000 to 60,000 miles. Proper maintenance tips for both belts include regular inspection for cracks, fraying, and glazing, ensuring correct tension with a belt tension gauge, and keeping the belts free from oil or coolant contamination. Consistent maintenance and timely replacement prevent engine accessory failures and improve overall vehicle reliability.

DIY or Professional: Which Replacement Option is Best?

Drive belt replacement and serpentine belt replacement each require specific tools and mechanical knowledge, making professional service a safer choice for complex vehicles. DIY enthusiasts with moderate experience can handle drive belt replacement using a few hand tools and clear instructions, while serpentine belts often demand precise tensioning and belt routing that professionals can expertly manage. Evaluating your mechanical skill level and access to proper equipment is crucial when deciding between DIY and professional replacement to ensure vehicle safety and belt longevity.

Preventive Maintenance to Extend Belt Life

Regular inspection and timely replacement of drive belts and serpentine belts are critical preventive maintenance steps that significantly extend belt life by preventing cracks and wear from causing sudden failure. Proper tension adjustment and alignment during replacement reduce strain on the belts, enhancing durability and operational efficiency. Using high-quality, manufacturer-recommended belts ensures optimal resistance to heat and friction, further prolonging maintenance intervals and reducing downtime.

Drive Belt Replacement vs Serpentine Belt Replacement Infographic

cardiffo.com

cardiffo.com