Lean burn combustion reduces emissions by operating with excess air, leading to lower nitrogen oxide (NOx) and carbon monoxide (CO) levels compared to stoichiometric combustion. Stoichiometric combustion uses the exact air-to-fuel ratio for complete combustion but typically produces higher NOx due to increased combustion temperatures. Optimizing engine parameters to favor lean burn can significantly improve fuel efficiency and decrease harmful pollutants.

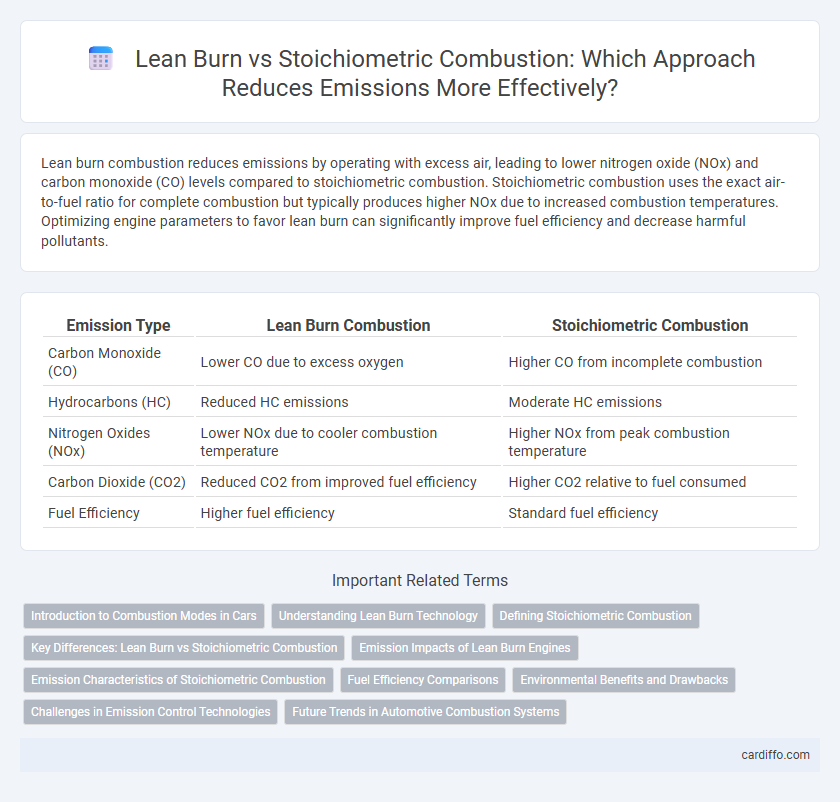

Table of Comparison

| Emission Type | Lean Burn Combustion | Stoichiometric Combustion |

|---|---|---|

| Carbon Monoxide (CO) | Lower CO due to excess oxygen | Higher CO from incomplete combustion |

| Hydrocarbons (HC) | Reduced HC emissions | Moderate HC emissions |

| Nitrogen Oxides (NOx) | Lower NOx due to cooler combustion temperature | Higher NOx from peak combustion temperature |

| Carbon Dioxide (CO2) | Reduced CO2 from improved fuel efficiency | Higher CO2 relative to fuel consumed |

| Fuel Efficiency | Higher fuel efficiency | Standard fuel efficiency |

Introduction to Combustion Modes in Cars

Lean burn combustion in cars operates with an excess of air compared to the stoichiometric ratio, resulting in lower fuel consumption and reduced carbon monoxide and hydrocarbon emissions. Stoichiometric combustion maintains an exact air-to-fuel ratio of 14.7:1, optimizing complete fuel oxidation for balanced performance and catalytic converter efficiency. Emission characteristics differ as lean burn reduces nitrogen oxide formation under specific conditions, while stoichiometric combustion promotes consistent emission control through precise exhaust after-treatment systems.

Understanding Lean Burn Technology

Lean burn technology reduces emissions by operating engines with excess air, promoting more complete combustion and lowering nitrogen oxide (NOx) and carbon monoxide (CO) outputs compared to stoichiometric combustion, which uses a precise air-fuel ratio. This approach enhances fuel efficiency and decreases particulate matter by minimizing unburned hydrocarbons through improved oxygen availability. Lean burn engines often utilize advanced sensors and control systems to maintain optimal air-fuel ratios, ensuring cleaner exhaust and compliance with stringent emission standards.

Defining Stoichiometric Combustion

Stoichiometric combustion occurs when fuel and oxygen are mixed in exact proportions, resulting in complete combustion with minimal unburned fuel or oxygen. This precise balance ensures optimal energy release and lower emissions of pollutants like carbon monoxide and hydrocarbons. In contrast to lean burn, stoichiometric combustion provides stable engine performance but may produce higher nitrogen oxide emissions under certain conditions.

Key Differences: Lean Burn vs Stoichiometric Combustion

Lean burn combustion operates with excess air, resulting in lower fuel consumption and reduced emissions of carbon monoxide and unburned hydrocarbons, while stoichiometric combustion uses the exact air-fuel ratio for complete combustion. Lean burn engines typically produce higher nitrogen oxide (NOx) emissions due to higher combustion temperatures, whereas stoichiometric engines facilitate better control of NOx through catalytic converters. The distinct air-fuel mixture strategies directly influence engine efficiency, emission profiles, and after-treatment system requirements.

Emission Impacts of Lean Burn Engines

Lean burn engines reduce nitrogen oxide (NOx) emissions by operating with excess air, resulting in lower combustion temperatures that inhibit NOx formation. However, they tend to increase hydrocarbon (HC) and carbon monoxide (CO) emissions due to incomplete combustion under lean conditions. Advances in catalytic converter technology and precise air-fuel mixture control help mitigate these emissions while maintaining the benefits of reduced NOx output.

Emission Characteristics of Stoichiometric Combustion

Stoichiometric combustion occurs when fuel and air are mixed in exact proportions, resulting in near-complete combustion and minimized unburned hydrocarbons and carbon monoxide emissions. However, this precise balance tends to produce higher nitrogen oxides (NOx) emissions due to elevated combustion temperatures. Emission control technologies like three-way catalytic converters are essential to reduce NOx while maintaining low hydrocarbon and CO emissions in stoichiometric combustion systems.

Fuel Efficiency Comparisons

Lean burn combustion achieves higher fuel efficiency by maintaining an air-to-fuel ratio greater than the stoichiometric ratio, resulting in more complete fuel oxidation and reduced fuel consumption. Stoichiometric combustion operates at an ideal air-to-fuel ratio where all fuel and oxygen theoretically react completely, but it often leads to higher fuel usage and increased emissions due to less optimized combustion conditions. Studies indicate lean burn engines can improve fuel economy by up to 15% compared to stoichiometric engines, especially under light-load driving conditions.

Environmental Benefits and Drawbacks

Lean burn combustion operates with excess air, reducing nitrogen oxides (NOx) and carbon monoxide (CO) emissions but can increase nitrogen oxide output if air-fuel ratios are not precisely controlled. Stoichiometric combustion achieves a balanced air-fuel ratio that maximizes fuel efficiency and minimizes unburned hydrocarbons but tends to produce higher NOx emissions due to hotter combustion temperatures. Environmental benefits of lean burn include lower greenhouse gases and improved fuel economy, while stoichiometric combustion offers easier implementation of catalytic converters despite higher NOx formation.

Challenges in Emission Control Technologies

Lean burn combustion reduces fuel consumption and NOx emissions but complicates emission control due to excess oxygen in the exhaust, which hampers the effectiveness of three-way catalysts. Stoichiometric combustion maintains an ideal air-fuel ratio, enabling optimal performance of catalytic converters but results in higher CO and HC emissions that require stringent after-treatment systems. Balancing these trade-offs presents significant challenges in developing advanced emission control technologies that meet strict regulatory standards while maintaining engine efficiency.

Future Trends in Automotive Combustion Systems

Lean burn combustion systems reduce fuel consumption and CO2 emissions by operating with excess air, enhancing engine efficiency and lowering nitrogen oxide formation through advanced catalytic converters. Stoichiometric combustion remains dominant due to tighter emission control compatibility, but future trends emphasize lean burn integration with hybrid and electrified powertrains to meet stringent global emission standards. Ongoing developments in sensor technology and real-time combustion control are critical for optimizing air-fuel ratios and minimizing harmful emissions in next-generation automotive engines.

Lean Burn vs Stoichiometric Combustion Infographic

cardiffo.com

cardiffo.com