Wheel coating offers long-lasting protection by forming a durable, hydrophobic layer that repels dirt, brake dust, and road grime, making wheels easier to clean. Wheel sealants provide a protective barrier but typically require more frequent reapplication due to their shorter lifespan and less robust chemical resistance. Choosing between wheel coating and wheel sealant depends on desired durability and maintenance frequency, with coatings favored for extended protection and sealants for quicker, budget-friendly use.

Table of Comparison

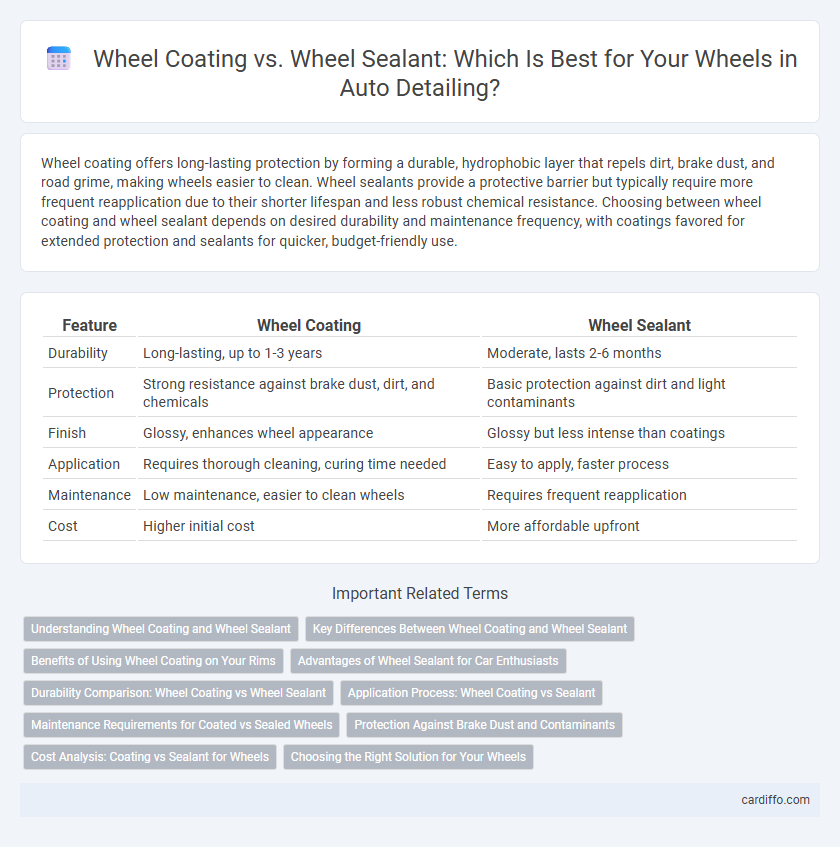

| Feature | Wheel Coating | Wheel Sealant |

|---|---|---|

| Durability | Long-lasting, up to 1-3 years | Moderate, lasts 2-6 months |

| Protection | Strong resistance against brake dust, dirt, and chemicals | Basic protection against dirt and light contaminants |

| Finish | Glossy, enhances wheel appearance | Glossy but less intense than coatings |

| Application | Requires thorough cleaning, curing time needed | Easy to apply, faster process |

| Maintenance | Low maintenance, easier to clean wheels | Requires frequent reapplication |

| Cost | Higher initial cost | More affordable upfront |

Understanding Wheel Coating and Wheel Sealant

Wheel coating offers a durable, long-lasting protective layer that shields wheels from brake dust, road grime, and UV damage by forming a chemical bond with the surface. Wheel sealant provides a protective barrier primarily by repelling water and contaminants, enhancing shine but typically lasting a shorter duration compared to coating. Understanding the key differences helps in selecting the right product for maintenance frequency, protection level, and desired finish on alloy or painted wheels.

Key Differences Between Wheel Coating and Wheel Sealant

Wheel coating offers a durable, long-lasting protective layer that bonds chemically with the wheel's surface, providing enhanced resistance against brake dust, road grime, and UV damage, typically lasting up to 12 months or more. Wheel sealant, on the other hand, creates a protective barrier by sitting on the surface, delivering water-repellent properties and moderate protection against contaminants but generally requires reapplication every 6 months. The main difference lies in longevity and bonding strength, with wheel coatings offering superior durability and deeper protection compared to the more temporary, surface-level defense of wheel sealants.

Benefits of Using Wheel Coating on Your Rims

Wheel coating offers superior protection for your rims by creating a durable, hydrophobic layer that resists brake dust, dirt, and road grime, reducing the frequency of cleaning. Unlike traditional wheel sealants, wheel coatings provide long-lasting resistance to corrosion and UV damage, preserving the appearance and structural integrity of your wheels. Enhanced chemical resistance and ease of maintenance make wheel coatings a cost-effective solution for maintaining pristine rims over extended periods.

Advantages of Wheel Sealant for Car Enthusiasts

Wheel sealants provide long-lasting protection against brake dust, road grime, and UV damage, preserving the wheel's finish for months with minimal maintenance. Their hydrophobic properties enhance water beading and make cleaning easier, reducing the frequency of detail sessions for car enthusiasts. Unlike traditional wheel coatings, wheel sealants offer flexibility in application and removal, allowing enthusiasts to maintain optimal wheel appearance without specialized tools.

Durability Comparison: Wheel Coating vs Wheel Sealant

Wheel coatings typically offer superior durability compared to wheel sealants, providing protection that can last up to 12 months or more under harsh conditions. Wheel sealants generally last between 3 to 6 months, making them a more frequent maintenance option but less resilient against brake dust and road salts. The enhanced chemical bonding properties of wheel coatings result in better resistance to corrosion and easier cleaning, ensuring long-term preservation of wheel finish.

Application Process: Wheel Coating vs Sealant

Wheel coating typically requires thorough surface preparation, including cleaning, decontamination, and curing time to ensure optimal bonding and durability. Sealant application is generally quicker, involving cleaning and wiping the surface before spreading a thin layer that dries faster but offers shorter protection. The coating process demands precision and patience for a chemical bond, while sealants provide a simpler, faster protective barrier suitable for regular maintenance.

Maintenance Requirements for Coated vs Sealed Wheels

Wheel coatings provide a longer-lasting protective layer requiring less frequent maintenance, typically needing reapplication every 12 to 24 months. Wheel sealants offer a durable barrier but demand more regular upkeep, with reapplication recommended every 3 to 6 months to maintain optimal protection. Proper maintenance for both involves routine cleaning with pH-balanced detergents to preserve the integrity of the coating or sealant.

Protection Against Brake Dust and Contaminants

Wheel coating provides a durable, long-lasting barrier that resists brake dust and contaminants more effectively than wheel sealant, which typically offers shorter-term protection. Advanced ceramic-based wheel coatings chemically bond to the wheel surface, creating a hydrophobic layer that repels dirt, grime, and brake dust buildup. Wheel sealants, while easier to apply, generally require more frequent reapplication to maintain a moderate defense against harsh environmental elements.

Cost Analysis: Coating vs Sealant for Wheels

Wheel coating typically costs between $150 and $300 due to its advanced ceramic formula and longer durability, offering protection that can last up to 12 months. Wheel sealants are more budget-friendly, generally priced around $30 to $70, but require reapplication every 6 to 8 weeks for effective protection. Considering cost per month of protection, wheel coatings provide better long-term value despite a higher initial investment.

Choosing the Right Solution for Your Wheels

Wheel coating offers long-lasting protection with a durable ceramic layer that repels brake dust, dirt, and road grime for up to two years, making it ideal for owners seeking minimal maintenance. Wheel sealants provide a more affordable and quicker option, forming a protective barrier that shields wheels from contaminants but typically require reapplication every few months. Selecting the right solution depends on factors such as desired longevity, budget, and how often you are willing to perform detailing upkeep on your wheels.

Wheel Coating vs Wheel Sealant Infographic

cardiffo.com

cardiffo.com