An orbital buffer uses a random orbit motion that reduces swirl marks and is ideal for beginners or light polishing tasks. A rotary buffer spins in a single, consistent direction, delivering more power and faster paint correction but requires advanced skill to avoid damaging the paint. Choosing between the two depends on the desired finish quality and user experience level in detailing.

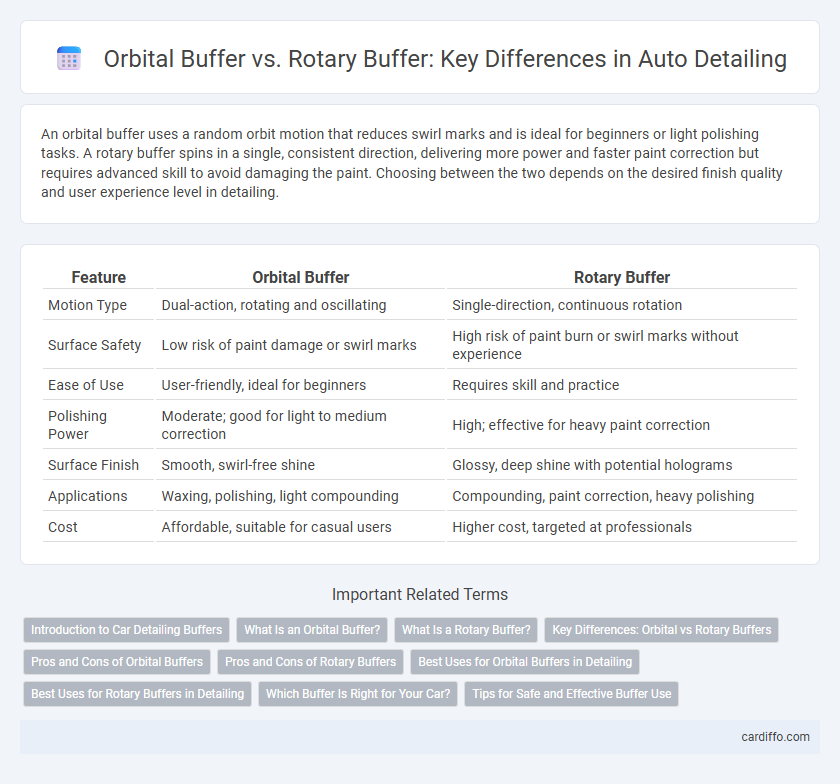

Table of Comparison

| Feature | Orbital Buffer | Rotary Buffer |

|---|---|---|

| Motion Type | Dual-action, rotating and oscillating | Single-direction, continuous rotation |

| Surface Safety | Low risk of paint damage or swirl marks | High risk of paint burn or swirl marks without experience |

| Ease of Use | User-friendly, ideal for beginners | Requires skill and practice |

| Polishing Power | Moderate; good for light to medium correction | High; effective for heavy paint correction |

| Surface Finish | Smooth, swirl-free shine | Glossy, deep shine with potential holograms |

| Applications | Waxing, polishing, light compounding | Compounding, paint correction, heavy polishing |

| Cost | Affordable, suitable for casual users | Higher cost, targeted at professionals |

Introduction to Car Detailing Buffers

Orbital buffers and rotary buffers are essential tools in car detailing, designed to enhance paint surface restoration and polishing. Orbital buffers operate with a dual-action motion, reducing the risk of paint damage by evenly distributing pressure, making them ideal for beginners and delicate finishes. Rotary buffers use a single spinning motion with higher speed and aggressiveness, offering faster correction of deep scratches and oxidation but require more skill to avoid paint swirl marks.

What Is an Orbital Buffer?

An orbital buffer is a power tool designed for paint correction and surface polishing, featuring a circular pad that moves in small, random orbits to minimize swirl marks and enhance finish quality. Its dual-action mechanism combines rotation and oscillation, making it user-friendly for beginners while delivering professional-grade results on automotive paint, glass, and metal surfaces. Compared to rotary buffers, orbital buffers generate less heat, reducing the risk of paint damage and providing greater control during detailing tasks.

What Is a Rotary Buffer?

A rotary buffer is a high-speed polishing tool that uses a circular, spinning pad to aggressively remove contaminants, oxidation, and imperfections from surfaces like automotive paint. Its consistent rotation allows for deep cutting and fast correction, making it ideal for heavy defects and smoothing rough surfaces. Unlike orbital buffers, rotary buffers do not oscillate, resulting in greater power but requiring skill to avoid swirl marks or paint damage.

Key Differences: Orbital vs Rotary Buffers

Orbital buffers feature a dual-action mechanism that combines spinning and oscillating movements, reducing swirl marks and making them ideal for beginners or light detailing. Rotary buffers spin in a single, consistent direction at higher speeds, offering aggressive cutting power suited for experienced users tackling heavy oxidation or deep scratches. The key difference lies in orbital buffers providing safer, user-friendly polishing with less risk of paint damage, while rotary buffers deliver more precise correction but require skill to avoid burn-throughs.

Pros and Cons of Orbital Buffers

Orbital buffers offer superior ease of use and reduced risk of paint damage due to their dual-action motion, making them ideal for beginners and delicate surfaces. They generate less heat and swirl marks compared to rotary buffers, enhancing paint protection and finish quality. However, orbital buffers are less aggressive and slower at removing deep scratches and heavy oxidation, limiting their effectiveness for more severe paint correction tasks.

Pros and Cons of Rotary Buffers

Rotary buffers offer superior cutting power and faster correction on heavily oxidized or scratched paint surfaces, making them ideal for professional detailers and advanced users. Their aggressive spinning motion can generate more heat, increasing the risk of paint damage or burn-through if not handled properly, which requires skill and careful technique. While rotary buffers excel in efficiency, they demand higher user experience and caution compared to the forgiving nature of orbital buffers.

Best Uses for Orbital Buffers in Detailing

Orbital buffers excel in automotive detailing by providing a swirl-free finish, making them ideal for applying wax, sealants, and sealant glazes on delicate surfaces. Their dual-action motion reduces the risk of paint damage and overheating, ensuring safe use on clear coats and softer automotive paints. Professionals often prefer orbital buffers for fine polishing and removing light oxidation, as their controlled movement preserves the vehicle's original finish while enhancing gloss.

Best Uses for Rotary Buffers in Detailing

Rotary buffers are best used for restoring heavily oxidized or severely damaged paint due to their high-speed rotary action, which delivers intense cutting power. They excel in correcting deep scratches, swirl marks, and sanding defects on hard, clear-coated surfaces when used with the appropriate compound and pad combinations. Professional detailers favor rotary buffers for their efficiency in paint correction, but they require skill to avoid burn-through or holograms on delicate finishes.

Which Buffer Is Right for Your Car?

Orbital buffers are ideal for beginners and detailers seeking a safe, swirl-free finish due to their random motion that reduces the risk of paint damage. Rotary buffers deliver faster results and are preferred by professionals for heavy oxidation and deep scratches but require skill to avoid burning the paint. Choosing the right buffer depends on your experience level, paint condition, and the desired finish quality.

Tips for Safe and Effective Buffer Use

Use an orbital buffer for beginners due to its controlled, random motion that reduces the risk of paint burning while a rotary buffer suits experienced users requiring aggressive compounding. Maintain moderate pressure and consistent speed with both buffers, wearing protective gloves and eye protection to prevent injuries from debris. Ensure the buffer pad is clean and properly attached, and avoid holding the buffer in one spot to prevent swirl marks and clear coat damage.

Orbital Buffer vs Rotary Buffer Infographic

cardiffo.com

cardiffo.com