Dry ice blasting removes contaminants efficiently without damaging surfaces or leaving residue, making it ideal for delicate parts and complex geometries. Traditional degreasing often relies on harsh chemicals that can cause environmental harm and require extensive cleanup. Choosing dry ice blasting enhances sustainability and reduces downtime compared to conventional methods.

Table of Comparison

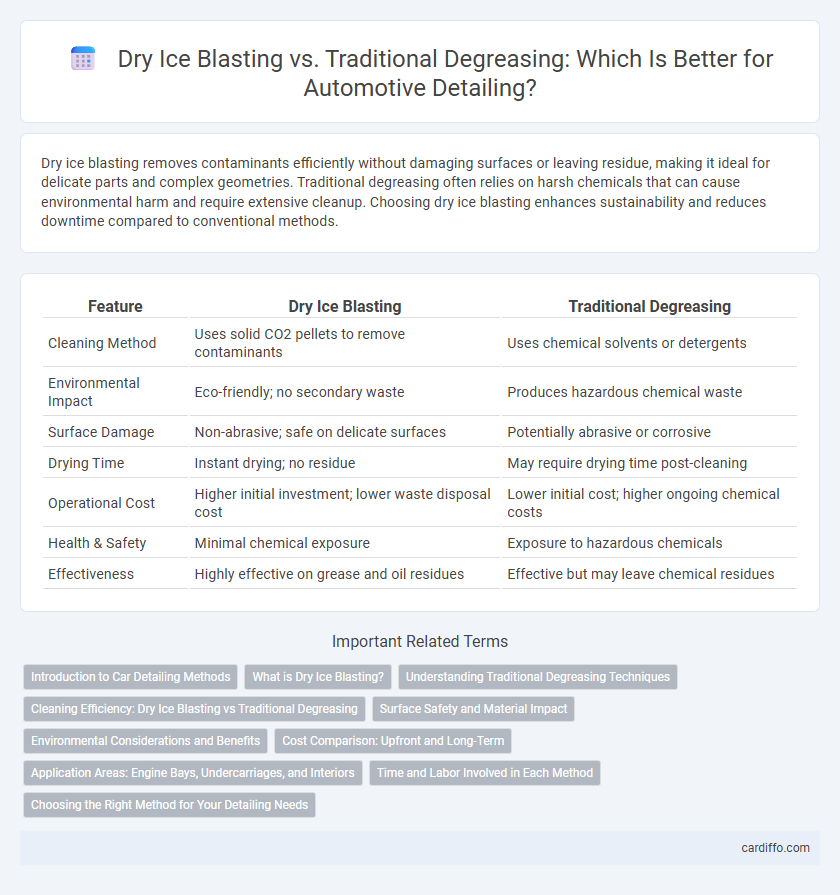

| Feature | Dry Ice Blasting | Traditional Degreasing |

|---|---|---|

| Cleaning Method | Uses solid CO2 pellets to remove contaminants | Uses chemical solvents or detergents |

| Environmental Impact | Eco-friendly; no secondary waste | Produces hazardous chemical waste |

| Surface Damage | Non-abrasive; safe on delicate surfaces | Potentially abrasive or corrosive |

| Drying Time | Instant drying; no residue | May require drying time post-cleaning |

| Operational Cost | Higher initial investment; lower waste disposal cost | Lower initial cost; higher ongoing chemical costs |

| Health & Safety | Minimal chemical exposure | Exposure to hazardous chemicals |

| Effectiveness | Highly effective on grease and oil residues | Effective but may leave chemical residues |

Introduction to Car Detailing Methods

Dry ice blasting uses solid CO2 pellets to remove grease and contaminants from car surfaces without water or chemicals, leaving no residue behind. Traditional degreasing typically involves chemical solvents and water, which can require additional rinsing and may pose environmental concerns. This advanced method offers a faster, eco-friendly alternative for deep cleaning during car detailing.

What is Dry Ice Blasting?

Dry ice blasting is an advanced cleaning method that uses solid carbon dioxide pellets propelled at high speeds to remove contaminants without abrasive damage. This environmentally friendly technique eliminates the need for chemical solvents and water, making it ideal for delicate surfaces and complex machinery. Its non-conductive, residue-free cleaning process significantly reduces downtime compared to traditional degreasing methods.

Understanding Traditional Degreasing Techniques

Traditional degreasing techniques typically involve the use of chemical solvents such as chlorinated hydrocarbons, alkaline cleaners, or emulsifiers to dissolve and remove grease, oil, and contaminants from surfaces. These methods often require extensive rinsing and produce hazardous waste, necessitating careful disposal and environmental considerations. Despite their effectiveness, traditional degreasing processes can be time-consuming, pose health risks to workers, and may damage sensitive components or surfaces.

Cleaning Efficiency: Dry Ice Blasting vs Traditional Degreasing

Dry ice blasting offers superior cleaning efficiency compared to traditional degreasing by rapidly removing contaminants without leaving residue or requiring secondary waste disposal. Unlike chemical solvents used in traditional degreasing, dry ice pellets sublimate on contact, effectively eliminating oils, grease, and grime from surfaces with minimal downtime. This method ensures thorough cleaning of intricate equipment and sensitive components, reducing maintenance time and improving overall operational productivity.

Surface Safety and Material Impact

Dry ice blasting offers a non-abrasive cleaning method that preserves surface integrity by avoiding scratches and wear common in traditional degreasing techniques using solvents or abrasive media. It effectively removes grease without moisture or chemical residues, reducing the risk of corrosion or material degradation on sensitive surfaces. This eco-friendly approach minimizes downtime and extends the lifespan of equipment by maintaining original surface properties.

Environmental Considerations and Benefits

Dry ice blasting eliminates the need for chemical solvents, reducing hazardous waste and minimizing environmental pollution compared to traditional degreasing methods that often rely on toxic chemicals. This environmentally friendly technique uses carbon dioxide pellets that sublimate upon impact, leaving no secondary waste and reducing water consumption. As a sustainable alternative, dry ice blasting helps businesses lower their carbon footprint while maintaining effective and safe cleaning processes.

Cost Comparison: Upfront and Long-Term

Dry ice blasting typically incurs higher upfront costs due to specialized equipment and materials but reduces long-term expenses by minimizing labor and waste disposal fees. Traditional degreasing methods often have lower initial investment but can lead to increased recurring costs from chemical purchases, hazardous waste handling, and downtime for drying. Evaluating cost efficiency involves analyzing total operational expenses, environmental compliance, and equipment lifespan over extended periods.

Application Areas: Engine Bays, Undercarriages, and Interiors

Dry ice blasting excels in engine bays, undercarriages, and interiors by providing a non-abrasive, chemical-free cleaning method that reaches intricate components without causing damage. Traditional degreasing relies on solvents and manual scrubbing which can leave residues and increase downtime due to drying requirements. The precision and eco-friendly nature of dry ice blasting make it ideal for automotive detailing where preserving sensitive parts and minimizing environmental impact are critical.

Time and Labor Involved in Each Method

Dry ice blasting significantly reduces time and labor compared to traditional degreasing by eliminating the need for disassembly and lengthy drying periods. Traditional degreasing often requires manual scrubbing and chemical application, increasing labor intensity and overall process duration. This efficient, non-abrasive method streamlines cleaning workflows, enhancing productivity in industrial maintenance.

Choosing the Right Method for Your Detailing Needs

Dry ice blasting offers a non-abrasive, eco-friendly cleaning option ideal for delicate surfaces and sensitive components in automotive detailing, as it eliminates residue without the use of chemicals or water. Traditional degreasing methods are effective for heavy grease and oil removal but may involve harsh solvents that could damage finishes or require extensive rinsing. Selecting the right method depends on the level of contamination, surface sensitivity, environmental considerations, and desired cleaning efficiency in your detailing process.

Dry Ice Blasting vs Traditional Degreasing Infographic

cardiffo.com

cardiffo.com